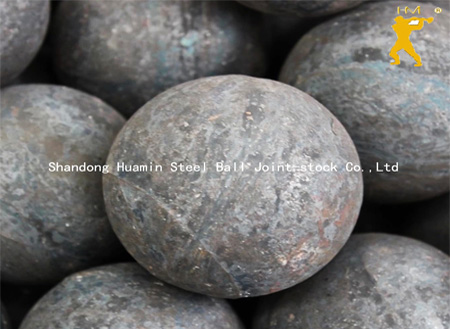

Forged Steel Grinding Balls

The forged steel grinding ball is excellent in surface quality, toughness, and resistance to impact and abrasion. It won't crack and lose circularity easily. The forging and stamping method that we use is that heating the metal until the temperature reaches 1050ºC (±50 ºC), and utilizing the metalforming machinery to exert pressure onto the metal blank, then the metal blank coming out with plastic deformation to become the forge piece with certain mechanical properties, shape and dimension.

The forging can eliminate the defects such as porous as-cast microstructure generated during the smelting process of the metal, and optimize the microstructure. Meanwhile, as a result of the preservation of the complete metal flow line, the forge piece has superior mechanical performance to the casting with the same material. The forged steel grinding ball must use the super wear resistant material to ensure the abrasion resistance, such as the high-carbon steel materials compliant with the national standard, or the high wear resistant alloy steel material researched and developed independently by some companies themselves.

We utilize the steel material manufactured by the national large steel mill. Even using the same material, different steel mills would produce the steel having different quality. The quality of the forge piece depends on the quality of the material by 80%. For example, the forge piece fabricated by using the high manganese steel has good toughness and resistance to impact and abrasion. It also won't crack easily. The forged steel grinding ball is favored by the majority of customers for low price, high economic durability, etc. Many large-scale related enterprises all utilize the product, such as the international mining giant of Rio Tinto, BHP Billiton, AngloGold Ashanti, etc.

Our product has precise size, high roundness, high hardness and mechanical properties. It is resistant to abrasion, and won't deform and crack. That can be fully shown from the aspects of high overall hardness, high surface hardness of up to 57HRC to 67HRC, high volume hardness as large as 56HRC to 64HRC, uniform hardness distribution, high impact toughness of greater than 12J/cm

We make a comparison of the consumption of the cast type and our forged rolled type steel grinding balls in a domestic iron ore plant with the result of 0.9kg/t and 0.6kg/t respectively. From the data, we can see that by using our product, the consumption for grinding every ton of ore is reduced by 33.3%.

在线联系供应商

Other supplier products

| Forged Grinding Balls | Forged Grinding Ball Features and Advantages:1. Surface hardness of up to 60HRC2. High volume hardness as large as 55HRC to 60HRC,uniform hardness ... | |

| Patented Automatic Steel Grinding Rod Production Line | By using the patented automatic steel grinding rod production line, the steel grinding rod has high straightness and toughness. It has high mechani... | |

| Steel Grinding Rods | Currently, most of the enterprises utilize the round bar steel rolled by the steel mill as the steel grinding rod directly. The round bar steel has... | |

| Grinding Steel Rod | Grinding steel rod, our company manufacture and export is as follows: 1. Specifications: 1) Size: Dia. 40 - 120mm, Length 3000-6000mm 2) Hardnes... | |

| Patented Automatic Steel Grinding Ball Production Line | The self-developed automatic steel grinding ball production line is our qualified product, and it has won Chinese invention patent. It uses electri... |

Same products

| HM Pumex Grinding Machine | 卖方: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro 电动研磨笔 IC 抛光工具 | 卖方: 深圳维客修科技有限公司 | XZZ Z1 Pro 电动抛光笔,配备多种磨头,满足不同类型的手机主板 CPU IC 研磨和维修需求。2025 XINZHIZAO XZZ USB 充电式抛光研磨笔,适用于手机维修。 XZZ ... | |

| Scraper Grinding Machine | 卖方: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| IC抛光用小型电动研磨笔 | 卖方: PHONEFIX technology Co.,Ltd | 描述E288-02小型手持研磨机迷你主板CPU IC抛光笔雕刻工具。电动研磨笔适用于手机维修,IC CPU抛光,玉石玛瑙,核雕,木雕,研磨铝板,印刷电路板和环氧板以及手机液晶屏残留OCA胶去除。... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | 卖方: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |