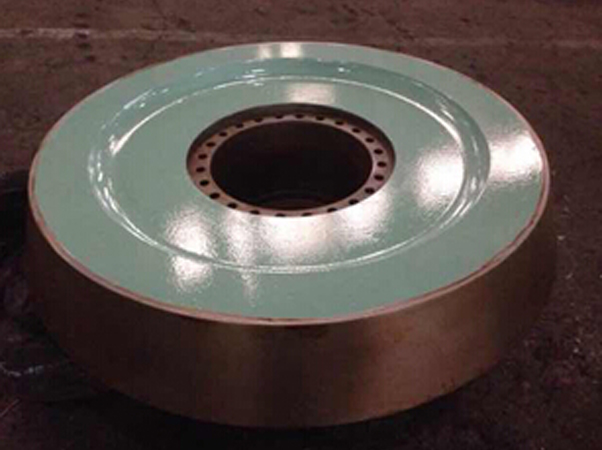

Supporting Roller

CIC is a more than 30 years manufacturer and reputed supplier of support roller used in rotary kilns, rotary type driers and so on. CIC has been specialized in designing, producing whole set of rotary machinery, so also has rich experience in supplying support device, such as support roller, support roller assembly and so on. CIC possesses professional design teams, advanced equipments and detecting method, strict quality control system to meet all your customized requirements of support roller. High quality, excellent performances and competitive price will make you rely on us and choose us. CIC has manufactured spheroidal cast iron supporting rollerwith max. diameter 1.5m, and high quality alloy steel support roller of max. diameter 2.1m.

Feature of Supporting Roller

Material: spheroidal cast iron, cast steel, forged steel and as your requests.

Standard: ANSI, API, ASTM, BSI, DIN, GB, ISO, JIS and more standards.

Mechanical Properties: customized requirements are accepted.

Hardness: customized requirements are accepted.

Surface treatment: rust preventive oil and according to your requirements.

Application: mainly used for supporting devices of rotary kilns, rotary type driers and so on.

QA and DOC: chemical composition report, mechanical properties report, sphere iodization rate report, UT report, PT report, heat treatment report, dimensions check report, hardness report and more.

We can offer third-party inspection.

Process: raw material purchasing - casting- rough machining - heat treatment - semi machining - finish machining - shrinkage fitting - painting and packing.

Various process conditions are available.

Certificates: ISO 9001:2008.

Products ability: Max OD: 2.5m.

Heat treatment: quenching and tempering, normalizing and tempering.

QC: fabrication schedule, fabrication process chart, inspection and test plan.

Packing: coated with rust preventive oil, wood- steel frame, seaworthy packing.

Our Advantage of Supporting Roller

More than 30 years of experience

ISO 9001:2008 Standard certified

Custom-made design

Strict quality control

Prompt delivery

More wearable

Lower noise

Longer service life

As one of the most professional heavy machinery manufacturers, CIC has high-quality sludge drying machinefor sale. Welcome to contact us if needed.

在线联系供应商

Other supplier products

| Thrust Roller | CIC is a more than 30-year manufacturer and reputed supplier of thrust roller used in rotary kilns, rotary type driers and so on. CIC has been spec... | |

| Furnace Tap Hole Machine | The manipulator is applied to the opening and plugging of the slag port in a copper smelting furnace. According to the copper smelting furnace slag... | |

| SAG Mill | Semi autogenous millor SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screen... | |

| Dry Ball Mill | Dry ball mill is suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and oth... | |

| Rotary Kiln | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... |

Same products

| HM Pumex Grinding Machine | 卖方: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro 电动研磨笔 IC 抛光工具 | 卖方: 深圳维客修科技有限公司 | XZZ Z1 Pro 电动抛光笔,配备多种磨头,满足不同类型的手机主板 CPU IC 研磨和维修需求。2025 XINZHIZAO XZZ USB 充电式抛光研磨笔,适用于手机维修。 XZZ ... | |

| Scraper Grinding Machine | 卖方: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| IC抛光用小型电动研磨笔 | 卖方: PHONEFIX technology Co.,Ltd | 描述E288-02小型手持研磨机迷你主板CPU IC抛光笔雕刻工具。电动研磨笔适用于手机维修,IC CPU抛光,玉石玛瑙,核雕,木雕,研磨铝板,印刷电路板和环氧板以及手机液晶屏残留OCA胶去除。... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | 卖方: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |