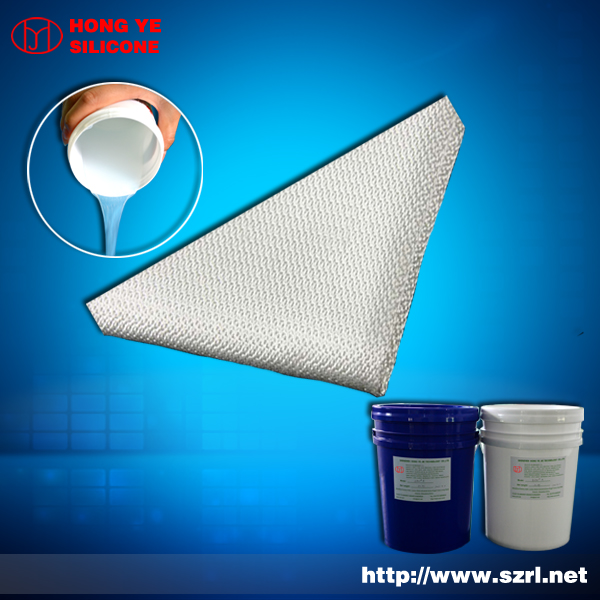

RTV molding silicone rubber for plaster products

Place of Origin: Guangdong China (Mainland) Brand Name: Hong Ye Silicone Rubber Min.Order Quantity: 200 Kilogram/Kilograms Supply Ability: 8 Ton/Tons per Day Port: shen zhen Payment Terms: L/C,T/T,Western Union Packaging Detail: 25kg/drum and 200kg/drum Delivery Detail: within 3 days after payment confirmed in our bank. Price: USD$6.88-8.98/KG RTV molding silicone rubber for plaster products application: RTV molding silicone rubber for plaster products with30 shore A, is specially suitable for plaster decoration duplication,gypsum sculpture reproduction,duplicating resin product with fine details,PU resin reproduction,wax molding,stone duplication ,epoxy moulds,pacrylic moulding,reproducing polyester craft. RTV molding silicone rubber for plaster products feature: (1)RTV molding silicone rubber for plaster products withSGSandROSHapproval (2)Curingagentarrangetogetherasfreecharged (3)Inliquidformandinvariouscolors (4)Withanexceptionalfluidityandgoodoperability. (5)Temperatureanddeformationresistanceaswellaslowshrinkage. (6)Highduplicationtimes. (7)Sampleordersareavailable RTV molding silicone rubber for plaster products datasheets: Model Color Mixing ratio (%) Pot life (mins) Demould time ( hrs) Hardness ( A0) Tensile-strength Tear-strength Viscosity (mPas) Shrinkage rate (%) Elongation (%) 630# white 100 :5 30-40 3-5 29-31 49kgf/cm2 ≥ 33kgf/cm 27000 ≤0.3% 490% Dowcorning3481 white 100 : 5 30-45 5-6 22-25 4.6Mpa 23kN/m 25000 ≤0.5% 520% Bluestar(3325 /585) white 100 : 5 20-60 6-24 25-28 4.2Mpa 26kN/m 35000 ≤0.7% 440% Wacker®M4503 white 100 : 5 30-90 10-20 25 5.0(N/mm² > 20N/mm 40000 ≤0.5% 350% SmoothonMoldMax®25 white 100 : 5 45 24 25 577psi 130pli 25000 002in./in. 375% RTV molding silicone rubber for plaster products operation way: Step One:Take 100g of part A and add 2g of part B and mix the silicone rubber and curing agent evenly. Step Two: vacuum pumping.Without exception, this step takes less than 10 minutes. Note: The time for vacuum-pumping should be less than 3—5 mins , otherwise, once the silicone rubber has cross-link reaction during vacuumizing, it will not be operated. Step Three: Brushing cast & Perfusion Molding operation RTV molding silicone rubber for plaster products frequentlyasked question: Why is the silicone rubber mold oily? Basically, molding silicone rubber doesn't contain any oil, so it won't be oily. The reasons for the oily molds can be deducted from the below 3 factors: 1. Added white oil, which is the compound of silicone oil and white oil. The white oil is not silicone oil but a kink of petrochemicals; 2.Added too much silicone oil. Normally, we donot advise our customers to add any silicone oil into silicone rubber. If necessary, the ratio must be 5%-10%; Any questions,please feel free to contact Rebecca: TEL : FAX : MOBILE : Gmail:Rebecca19921124@ Website: E-MAIL: hyjcc(at)

Other supplier products

供应产品

Same products