Organic Compound Comprehensive Tester RoHS 2.0 Tester LC-2800G Plus

Features of Organic Compound Comprehensive Tester RoHS 2.0 Tester LC-2800G Plus

It is equipped with JHT test V chromatography software to realize the whole process computer control of the instrument, reduce the manual sampling error and improve the accuracy.

The infusion pump, column temperature box, detector, etc. all have the real-time leakage alarm monitoring function, providing guarantee for users to realize unattended operation.

The plunger rod is automatically cleaned to realize automatic online cleaning and reduce instrument loss and failure rate.

Shimadzu automatic sampler is selected to realize 24-hour unmanned automatic test, which can effectively reduce the manual workload with the data batch processing function.

The appearance of the whole machine adopts piano baking paint, two-color indicator light, keyless design, beautiful and generous.

JHT test V chromatographic workstation is specially designed for RoHS testing, which is easy to operate and realizes human-computer interaction.

The whole machine is equipped with degasser module to avoid bubbles generated by injector or gradient mixing, reduce baseline noise and baseline drift.

Completely separate the 4P spectrum peak of o-benzene, and improve the accuracy of qualitative and quantitative analysis.

The chromatographic data processing system has strict authority management function, built-in database management data, which can achieve audit tracking, ensure the safety and reliability of data, and comply with relevant regulations.

1、 Industrial Applications

The organic compound comprehensive tester, abbreviated as HPLC, is an analytical method for separating organic substances. As an important branch of chromatography, liquid is used as mobile phase, and high pressure infusion system is used to pump mobile phase such as single solvent with different polarity or mixed solvent with different proportion and buffer solution into chromatographic column with fixed phase. After each component in the column is separated, it enters detector for detection, so as to realize analysis of sample. This method has become an important application of separation and analysis technology in the fields of chemistry, medicine, industry, agriculture, commodity inspection and legal inspection.

LC-2800G Plus is an upgraded liquid chromatography product based on LC-2800G, which mainly deals with RoHS 2.0 substance detection in the electronic and electrical industry. The product can realize the separation and detection of most organic compounds. These include dealing with polybrominated biphenyls and polybrominated diphenyl ethers in RoHS directive, phthalates in REACH directive, California 65 phthalate test, formaldehyde and polycyclic aromatic hydrocarbons in EN71 toy directive; And the test of organic substances: fumaric acid, bisphenol A, azo fuel, nonylphenol, aromatic amine and other substances.

2、Coping With Detection

Coping detection: phthalates (PAEs), polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), azo dyes (AZO), polycyclic aromatic hydrocarbons (PAHs), formaldehyde (Formaldehyde), fumaric acid (DMFU), dimethylformamide (DMFA), bisphenol A (BPA), nonylphenol (NP), RoHS 2.0 regulations, CP 65 regulations, REACH regulations should be equivalent

3、Product Overview

1. Detector

1) The flow cell with parallel double tapered holes greatly improves the signal-to-noise ratio, and the detection effect is better;

2) The power on self-test function is used to judge the accuracy of wavelength indication error through the positions of 254nm and 350nm on the spectrum, ensure the excellent wavelength accuracy, and ensure the best state of the instrument;

3) The control circuit adopts high-performance processor, and the software adopts multitask processing program control, which can realize the functions of switching the deuterium lamp, spectral scanning, starting the analysis program, etc.

4) Digital signal output mode to avoid distortion and interference caused by signals; The whole process digital filtering can reduce the baseline noise and drift, improve the signal-to-noise ratio and anti-interference capability;

5) Time wavelength program can be realized, with automatic baseline zeroing function, real-time switching operation of online analysis wavelength, and the maximum sensitivity of different absorbance compounds can be obtained;

6) Static wavelength scanning can scan the spectral information of the sample to obtain the UV characteristic spectrogram of the unknown compound and obtain the characteristic wavelength of the unknown compound;

7) The unique heat dissipation design of the deuterium lamp effectively reduces the thermal effect of the deuterium lamp and reduces baseline drift.

8) Meet GLP requirements, with automatic recording of instrument error, component replacement, deuterium lamp service time and other recording functions;

9) Wavelength range: 190~700nm; Spectral width: 8nm

10) Wavelength accuracy: ± 1nm

11) Wavelength repeatability: ≤ 0.1nm

12) Flow cell volume: 8 μ L

13) Baseline noise: ≤ 1 × 10-5

14) Baseline drift: ≤ 1 × 10-4AU

15) Minimum detection amount: 1 × 10-9g/mL

16) Size: 350 * 470 * 160mm

17) Weight: 16kg

4、Infusion Pump

1) The floating plunger installation mode is adopted to greatly extend the service life of the plunger rod and the sealing ring; The design of double plunger reciprocating tandem pump greatly reduces the failure rate of pump check valve (by 50%) and effectively saves maintenance costs;

2) The floating plunger rod driven by a small cam is adopted to greatly reduce the infusion pulsation and improve the flow accuracy; The double pump head design greatly reduces the pressure pulsation of the pump and increases the stability of infusion;

3) All pump heads are made of 316L imported stainless steel with strong wear resistance and corrosion resistance; The pump head is external for easy maintenance.

4) The seal ring is made of a new type of high polymer material with corrosion resistance and good sealing performance, which extends the service life of the seal ring and piston rod;

5) The peristaltic pump automatically cleans the plunger rod. Users can set different cleaning schemes to achieve automatic online cleaning; The plunger rod automatically retracts, facilitating the replacement of the sealing ring;

6) Process detection and alarm functions, real-time display of operating parameters;

7) The flow range that can be set is 0.001~9.999mL/min, and the increment is 0.001 mL/min

8) Flow accuracy: ≤ 0.2%; Flow precision: ≤ 0.06%

10) Pressure range: 0~42MPa; Display pressure error: ≤ 0.5MPa; Upper and lower limits can be set and automatic alarm can be given

11) Pressure pulsation ≤ 1.0%

11) Gradient mixing accuracy: ± 0.5%

12) Gradient mixing precision: ± 0.1%

13) Size: 350 * 470 * 160mm

17) Weight: 18kg

5、Nti Control Column Temperature Box

1) The chromatographic workstation reverses the column temperature box and displays the real-time temperature.

2) Temperature control range (oC): room temperature to 100oC;

3) Upper limit temperature protection (oC): 110 oC;

4) Temperature control accuracy (oC): ± 0.1;

5) Temperature stability (oC): ± 0.1;

6) Size: 350 * 470 * 160mm

7) Weight: 11kg

6、Software workstation

1) Instrument control, including the control of various parameters of pumps, detectors, automatic samplers, column temperature boxes and other instruments, and the instrument achieves full back control;

2) Status feedback, which can feed back the status of pump (flow, pressure), detector (wavelength, lamp on/off status, running time, opening times, energy, etc.) and column temperature box (real-time temperature display) in real time;

3) Many functions such as baseline monitoring, sequence analysis, data processing and report printing can be realized through software to realize software analysis automation

4) The chromatographic data processing system has strict authority management function, built-in database management data, which can realize audit tracking, ensure the safety and reliability of data, and comply with relevant regulations.

5) Software name: organic comprehensive test software, version: V1.0 or above.

6、 Reverse Version Automatic Sampler (Optional)

1) The chromatographic workstation has a fully reverse control version of the automatic sampler, providing guarantee for unattended sample testing.

2) Injection mode: Full Loop, Partial Loopfill, uL Pick up;

3) Injection volume: 0 – 100 μ L;

4)Injection precision: full quantitative ring<0.3% RSD, injection volume greater than 5 uL; Semi quantitative ring<0.5% RSD, injection volume greater than 5 uL; Microliter<1.0% RSD, injection volume greater than 5 uL;

7、Equipment Accessories

8、Technical Support And After-Sales Service

1. The product is guaranteed for 12 months, with lifelong maintenance

2. Provide customers with considerate technical support services before, during and after sales.

3. Pre sales consultation: pay attention to customer application needs, provide reasonable and professional solutions, and invite customers to experience operation on site.

4. On site installation training for professional engineers, training contents: background of hazardous substances, instrument operation to report, daily maintenance and cleaning of instruments, laboratory operation specifications and waste liquid treatment, sample classification and rating.

5. Operation training: provide a complete product manual, with pictures and videos, professional after-sales a training class every 1-3 months. Customers can receive professional training at home for free.

6. Customer return visit: visit customers quarterly to listen to their suggestions and help them solve problems encountered in the actual operation.

7. Service response: 4-hour response, 24-hour problem solving or standby instrument use.

8. Upgrade service: provide customers with free software upgrade service for life.

Comprehensively provide detection and control scheme services to respond to various environmental protection instructions, which can provide unlimited scalability.

According to user requirements and specific requirements of controlled materials, in combination with the technical characteristics of HPLC analysis, instrument analysis methods are incorporated into the user's quality control system to provide users with the best detection scheme and assist in establishing material acceptance standards; It also provides risk analysis methods for special materials.

For mor info about hplc testing machine and bga rework, contact us.

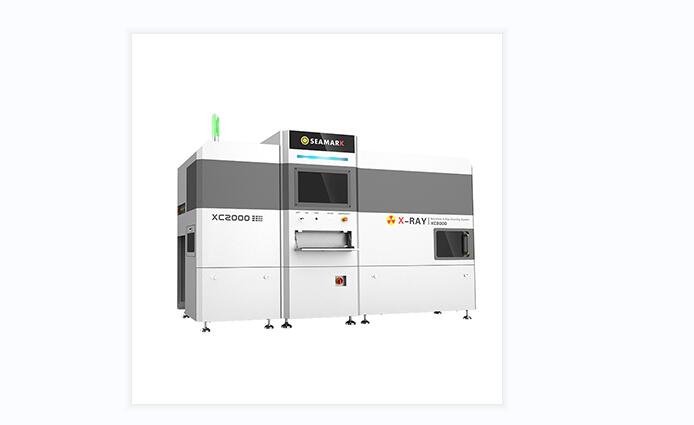

If you are looking for a reliable x ray inspection machine manufacturer, don't hesitate to contact us!

Other supplier products

|

|

Offline X-Ray Inspection Machine |

Seamark's 2D industrial x ray machine adopts a closed microfocus X-ray tube with voltage 90KV, 110KV, and 130KV, which meet different product inspe... |

|

|

Online Reel Counter |

X-Ray smd counter, also known as SMD component counter . The equipment adopts the principle of photoelectric sensing and uses the corresponding rel... |

|

|

Inline Inspection Machine for Winding Battery |

Seamark has three models of automated x ray inspection machines: the XB7100, XB7300, and XB8100. Inline automated X-ray inspection machines are pop... |

|

|

Microfocus X-Ray Inspection Machine |

Microfocus X-ray inspection is widely used in the LED/automobile/aerospace/EMS ETC field and become a necessity for modern PCBA inspection. As a pr... |

|

|

ZM-R8650 Fully Automatic BGA Rework Station |

R8650C fully bga rework station automaticis a fully automatic visual alignment BGA rework station. This BGA repair station can be used as an automa... |

供应产品

Same products