Crystallizer

Hongvadar is advanced in many areas, such as being the corn starch production plant and small scale tomato processing plant.

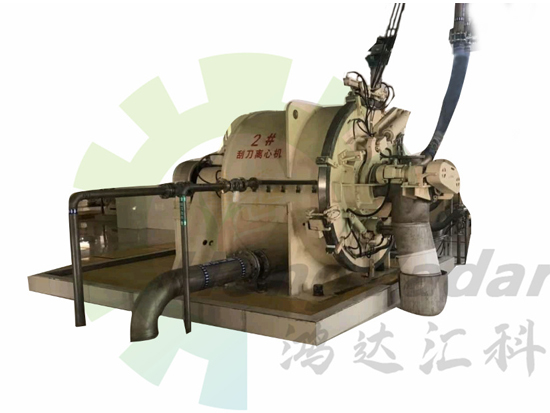

Horizontal Crystallizer

HVD-HCR-V horizontal agitated batch vacuum crystallizer is a piece of cooling crystallisation equipment. The source medium of crystallization coolingis operated under atmospheric pressure. The crystallization temperature is determined by the process and the crystallization process is discontinuous. Its crystallization control has outstanding characteristics are simple structure, energy-saving, and comfortable operation.

The crystallizer meaning is a horizontal closed cylinder structure, with packing sealing device and reduction gear installed on both end covers. The tank wall has a cooling water interlayer. The hollow shaft is arranged in the center of the tank to fix the cooling coil and agitating spiral belt. Both ends of the shaft heads have the function of cooling water circulation.

Application of Horizontal Crystallizer

lCrystallization of liquid glucose.

lCrystallization of glutamic acid, xylose, and xylitol.

lCrystallization of tartaric acid and malic acid.

lCrystallization of salts in the chemical industry.

lCrystallization of sodium gluconate, calcium carbonate.

Features of Horizontal Crystallizer

lCustomized design of equipment used in crystallizationto meet the needs of various customers.

lThe transmission device has a compact structure, stable operation, high efficiency, and low noise.

lReliable mechanical seal, shortstop time.

lThe small gap between the spiral belt and the barrel body, uniform stirring, not blocked.

lAdvanced circulating water cooling system with good cooling effect and high crystallization effect.

lStainless steel inner cylinder, corrosion resistance, long service life.

Cooling Different Types of Crystallization

HVD-VCR-V vertical continuous crystallizer is used to crystallize solids from the supersaturated solution by liquid crystallization. The solution is entered through the feed pipe at the top of the crystallizer. Through the cooling module in vertical and the cooling module in series to form a pre-designed temp. the gradient to cool the material. After the crystallized material reaches the bottom of the equipment, it reaches a certain temp. and particle size, and then it is discharged through the outlet with an insulation jacket at the bottom of the equipment into the next process for processing.

The seed needed for the surface cooled crystallizerprocess is supplied from the seed tank.

Application of Cooling Type Vertical Continuous Crystallizer

lCrystallization of liquid glucose.

lCrystallization of fructose, mannitol, and maltitol.

lCrystallization of glutamic acid, xylose, and xylitol.

lCrystallization of tartaric acid and malic acid.

lCrystallization of salts in the chemical industry.

lCrystallization of sodium gluconate, calcium carbonate.

Features of Cooling Type Vertical Continuous Crystallizer

lContinuous and large-scale production.

lAutomatic control to ensure stable product quality.

lThis equipment used for crystallisation can save floor space.

lSimple and convenient operation.

Crystallizer Technical Parameter

Horizontal Crystallizer Technical Parameters

|

Model |

HVD-HCR-V25 |

HVD-HCR-V30 |

HVD-HCR-V36 |

HVD-HCR-V40 |

HVD-HCR-V45 |

|

Volume (m3) |

25 |

30 |

36 |

40 |

45 |

|

Working pres. (Mpa) |

≤0.16 |

||||

|

Feed DS % |

70%~75% |

||||

|

Power (kw) |

3 |

4 |

|||

|

Rotary speed (r/min) |

|||||

|

Overall dimension (mm) |

5880×2980×3545 |

6680×2980×3545 |

7165×3250×3833 |

6305×3833×4045 |

6805×3600×4045 |

|

Weight (kg) |

13500 |

15200 |

18232 |

171000 |

18420 |

Cooling Type Vertical Continuous Crystallizer Technical Parameters

|

Model |

HVD-VCR-V110 |

HVD-VCR-V178 |

|

Volume (m3) |

128 |

178 |

|

Material loading volume (m3) |

110 |

160 |

|

Effective cooling area (m2) |

250 |

380 |

|

Material |

SS304 |

SS304 |

|

Cooling modules qty. |

11 (10 groups coil + head jacket) |

12 (11 groups coil + head jacket) |

|

Cooling control circuit |

5+1 (jacket) |

5+1 (jacket) |

|

Reducer power (kW) |

||

|

Power of hydraulic station (kW) |

15 |

22 |

|

Total height around (m) |

21 |

|

|

Barrel body (mm) |

Φ3300×8 |

Φ3800×8 |

在线联系供应商

Other supplier products

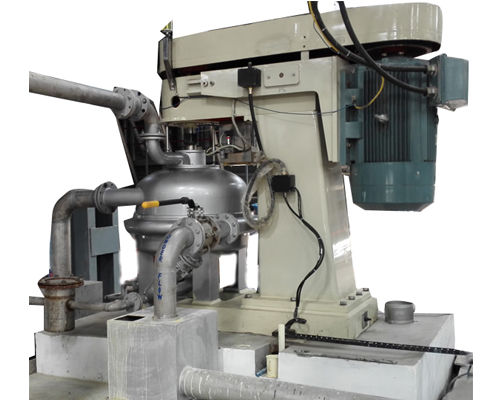

| Peeler Centrifuge | HVD-PC-P series horizontal peeler centrifuge working principle: after full running, opens the feed valve, the separated suspension through the ho... | |

| Full Automatic Intelligent Ion Exchange System | HongVadar Co. abides by the business philosophy of "Take honesty as the foundation and Keep credit to develop", adheres to the practice principles ... | |

| 12-stage Hydrocyclone System | VD-HC-D series 12 stage starch washing hydrocyclone systemis mainly used to extract refined starch milk, that is, to remove soluble and insoluble p... | |

| Disc Separator | In the starch separation process, HVD-SP-P series high speed separatorproduces very high centrifugal force due to high speed rotation, which improv... | |

| Chromatography System | Hongvadar is advanced in many areas, such as being the corn starch production plant and small scale tomato processing plant. HVD-CHRO-Q series chr... |

Same products

| Scaffold Sleeve Coupler | 卖方: SHIJIAZHUANG LANGHENG COMMERCE&TRADING CO., LTD | Scaffold Sleeve Coupler Scaffold Sleeve Couplersare known by various names depending on region o... | |

| Optical Brightener OB | 卖方: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Optical Brightener OB Optical brightener OB is poorly soluble in water, and soluble in alkane, m... | |

| Solvent Blue 36 | 卖方: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Solvent Blue 36 Solvent Blue 36is an industrial colorant with excellent tinting power and transp... | |

| Fast Scarlet G Base | 卖方: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Fast Scarlet G Base Basic informationof Fast Scarlet G Base: Product name: Fast Scarlet G Base ... | |

| Sulphur Black BR 200% | 卖方: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Sulphur Black BR 200% Product Name:Sulphur Black BR 200% :Sulphur Black 1 CAS No.:1326-82-... |