Calcium Aluminate Cement

Description of Calcium aluminate cementCalcium aluminate cement, alumina cements or high alumina cements are obtained by the reaction at high temperature of lime (from limestone) and alumina (contained in natural minerals like bauxite). The product obtained after cooling is a hard mineral: calcium aluminate clinker. Ground into a fine powder, the clinker becomes calcium aluminate cement (CAC) which forms a paste when mixed with water. This has the ability to harden very quickly: it forms a rigid solid within 24 hours.Application of calcium aluminate cementThere are two distinct ways to use calcium aluminates: as high-performancebindersand asmineral reagents in a variety of industries.As binders, calcium aluminates are used in concretes and mortars for specialized applications for their properties of resistance to corrosion, abrasion and heat combined with rapid hardening and the ease of controlling grading variations.Calcium aluminate cements are also used in combination with other fine components. Hydraulic binders with new properties are then obtained. In this way, aluminates act as both a complex hydraulic binder and a mineral reagent interacting with the other components in the mix.As reagents, calcium aluminatesare found in non-hydraulic systems. This is the case in metallurgical treatments (iron and steel industry, foundry) where specific grades of calcium aluminate are used for their low-temperature melting properties and for trapping molten metal impurities.

Calcium Aluminate Cement Construction method:1. When preparing refractory concrete, fix on the aggregate according to using condition. Choose the proper capacity graduation to make maximum density. Be noted to match and adapt with cementing material.2. According to certain proportion, add water and mix by man or machine into mortar and then begin casting construction. Use up the ready mortar within 40 min. Calcium Aluminate Cement’s hydration heat concentrate on early stage. Casting thickness should not exceed 3 cm each time. Water curing immediately when concrete goes hardening and the curing time should not less than 3 days.3. When prepare expanding cement, Calcium Aluminate clinker’s dosage is 73-76%, CaSO4·2H2O dosage is 24-27%. When prepare self-stressing cement, the mixing ratio of CaSO4·2H2O should be increased.Calcium Aluminate Cement Notice:1. In order to avoid uncontrollable setting time, do not mix with Portland cement, lime etc of which separate out calcium hydroxide cementing material. Before use, clean all the mixing machinery.2. Steam curing to accelerate concrete’s hardening. The curing temperature should not higher than 50℃.3. Refractory concrete’s late strength decline big, design should according to the lowest stable strength. CA-50 bonded concrete’s lowest stable strength should be determined by the lowest strength of 7-14 days of demoulding sample curing in 20℃±1℃ water.

Calcium aluminate Cement Packing:by 50kgs bag. Store in shady, cool and dry place. Avoid stamp and mix with other substance.

Where toBuy Calcium Aluminate Cement

We are professional inhigh alumina cement manufacturing process andproduce excellentCalcium Aluminate cement, high alumina cement and high temperature alumina cement supplier, please feel free to contact us.

Oreworld trade (Tangshan) co., Ltd. has been engaged in exporting business for about 20 years.It is a professional cement supplier. If you want to know more details or want a quotation, just feel free to contact us!

在线联系供应商

Other supplier products

| Calcium Aluminate Cement | Description of Calcium Aluminate Cement High temperature alumina cement, alumina cements or high alumina cements are obtained by the reaction at h... | |

| Calcium Aluminate Cement | Description of Calcium Aluminate Cement Calcium high temperature alumina cement, alumina cements or high alumina cements are obtained by the react... | |

| Clay Insulation Brick | Thermal Insulation Bricksare high porosity refractories with low thermal conductivity and high porosity (no less than 45%) used to reduce heat loss... | |

| Calcium Aluminate Cement | Description of Calcium Aluminate Cement Calcium aluminate cement, alumina cements or high alumina cements are obtained by the reaction at high tem... | |

| High Alumina Cement | What is High Alumina Cement High alumina cement concrete(HAC, sometimes known as calcium aluminate cement (CAC) or aluminous cement) is composed o... |

Same products

| High Alumina Cement | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | What is High Alumina Cement High Alumina Cement (HAC, sometimes known as calcium aluminate cemen... | |

| Calcium Aluminate Cement | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | Description of Calcium AluminateCement Calcium aluminate cement, alumina cements or high alumina... | |

| CSA Cement | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | What Is CSA Cement? CSA (Calcium Sulfoaluminate Cement) cement is a special cement used in many ... | |

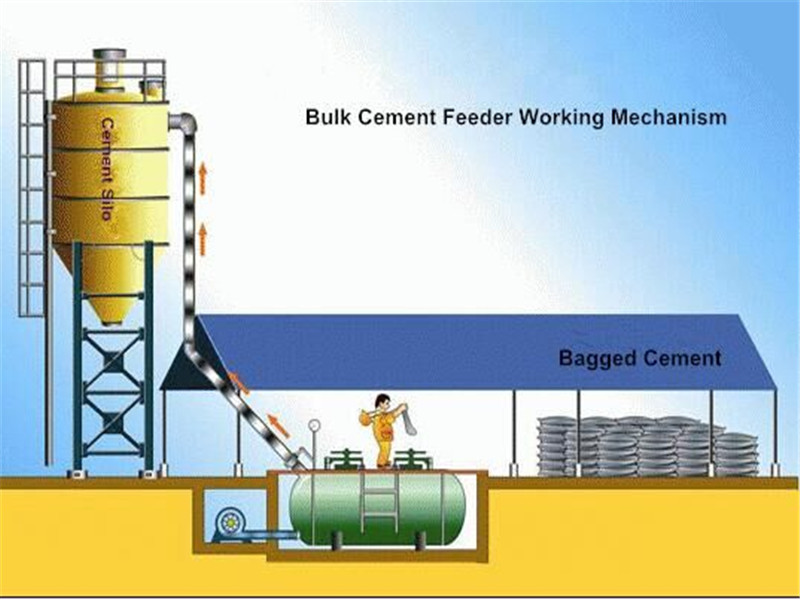

| bag cement feeding system | 卖方: Henan Shengmao Machinery Co., Ltd | Normally, we use bulk cement tanker to deliver cement to the concrete batching plant. On the bu... | |

| CSA Binder | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | CSA Binder Introduction: Calcium Sulfoaluminate binder is pure CSA clinker that grinded withou... |