Scale Breaker

Scale-breaking tension leveller, also called scale breaker, is generally used for continuous pickling units. Scale breaker machine applies to bend stress to strip steel. The front and rear bridle roll applys tensile stress to the strip; Under the coordination of these two stresses, the strip can produce moderate elongation under the condition that the tensile stress is far below the yield limit of the material. On the one hand, this extension realized by scale breaker can improve the shape of the strip and eliminate the defects such as wave, buckling and camber, at the same time, the internal stress and yield platform are eliminated to improve the mechanical properties of the strip. On the other hand, due to the huge difference between the oxide layer on the surface of strip steel and the iron matrix in performance, under the action of bending and stretching, a large number of oxide layer will fall off, and the oxide layer still attached to the surface will also crack, so as to improve the efficiency of acid tank pickling descaling.

Scale Breaker Application Scope

Scale Breaker Tension Leveler (Dry Type) Application Scope

|

Material |

Material Thickness |

Strip Width |

Yield Strength |

Leveling Speed |

|

Carbon Steel, Stainless steel |

700-1850mm |

≤1000MPa |

≤360m/min |

Scale Breaker (Wet Type) Application Scope

|

Material |

Strip Thickness |

Strip Width |

Yield Strength |

Leveling Speed |

|

Stainless steel |

700-1550mm |

≤500MPa |

≤150m/min |

Scale Breaker Structure Advantages

Structure Advantage of Scale Breaker Tension Leveler (Dry Type)

Two sets of bending unit and one set of leveling unit of the flat rolling machine can effectively remove the oxide skin on the surface of the strip and improve the shape of the strip. Two sets of bending units can also be used for one use and another one as spare according to the conditions of incoming materials and process requirements.

Dry type scale breaker is equipped with blowing system, sealing system and dust collection and dust removal air net, to ensure the environment of equipment usage, at the same time to effectively collect the broken oxide scale.

The frame of scale breaker is an assembly part, each part is annealed separately to eliminate participating stress and ensure the frame is not deformed after long-term use. At the same time, it also provides convenience for later maintenance.

The roller changing device is safe and convenient. The dry type scale breaker is driven by hydraulic pressure. One or all of the roller boxes can be replaced at one time.

The top roller system of dry type scale breaker can be opened quickly to prevent the rolls being damaged when weld seam passing. The lower roller system is used for improving the version by adjusting the insertion amount of the lift. The ball cage coupling is used to connect the driving motor, the lift and the detection encoder to facilitate the flexible adjustment and maintenance.

Structure Advantage of Scale Breaker (Wet Type)

There are two sets of bending units and one set of leveling unit of scale breaker, which can remove the oxide skin on the surface of the strip effectively and improve the shape of the strip. Two sets of bending units of scale breaker can also be used for one use and another one as spare according to the conditions of incoming materials and process requirements.

The frame is an assembled part, and each part is annealed separately to eliminate participating stresses and ensure that the frame is not deformed for long-term use, which also provides convenience for later maintenance.

The roller changing device of the wet type scale breaker is safe and convenient. It adopts hydraulic drive and can replace one cassette or all cassettes at a time.

The top roll system can be opened quickly to prevent roll damaged when welding seam passing, and the top roll system is adjusted by the cylinder to improve the flatness.

The top roller system and the inner wall of the frame have taken effective medium anti-rust measures, which can effectively prevent rust water from dripping on the surface of the strip and affecting the quality of the strip.

Wet type scale breaker is equipped with spray device to clean the oxide scale on the surface of the strip and roll and to ensure the descaling effect.

The main machine of scale breaker has taken effective waterproof, anti-rust measures, good sprinkler and backwater system, which can ensure long-term reliable and stable operation of equipment.

As a professioal metal machinery supplier, we will try our best to keep every buyer updated with this highly competitive industry and the latest scale breaker trends. If you are looking for scale breakers, we will provide you with the latest technology and the competitive scale breaker price to enhance your sourcing efficiency in the business line of manufacturing & processing machinery.

Boya company, as an excellent tension levelermanufacturer, offers a wide range of flat rolling for you to choose from.

在线联系供应商

Other supplier products

| Tension Leveler for Galvanizing Line | Galvanizing line tension leveler is a continuous stretching bending straightening machine that is used in the continuous hot-dip galvanizing line. ... | |

| Scale Breake | Scale Breaker Scale-breaking tension leveller, also called scale breaker, is generally used for continuous pickling units. Scale breaker machineapp... | |

| Side Trimming Line | Side trimmer is the BOYA advantage product, in shear theory, tension control, BOYA has deep research, and is used in many patented technology. The ... | |

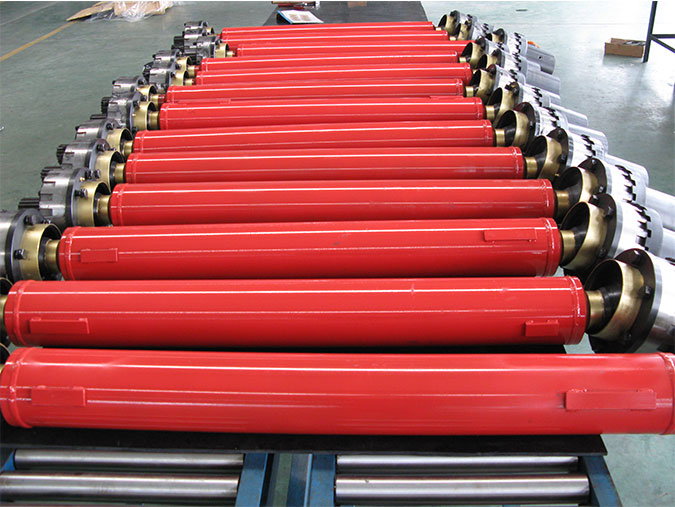

| CV Joint Bearing For Steel and Non-ferrous Metal Industries | The main CV jointbearing is ball cage type, designed and developed BJ, BHJ, BJS, BC, DOJ five categories, compared to NTN, the model specification ... | |

| Tension Leveling Line | Tension leveleris one of the most advantageous product of BOYA, BOYA has deep research in leveling theory, tension control and so on, and is used i... |

Same products

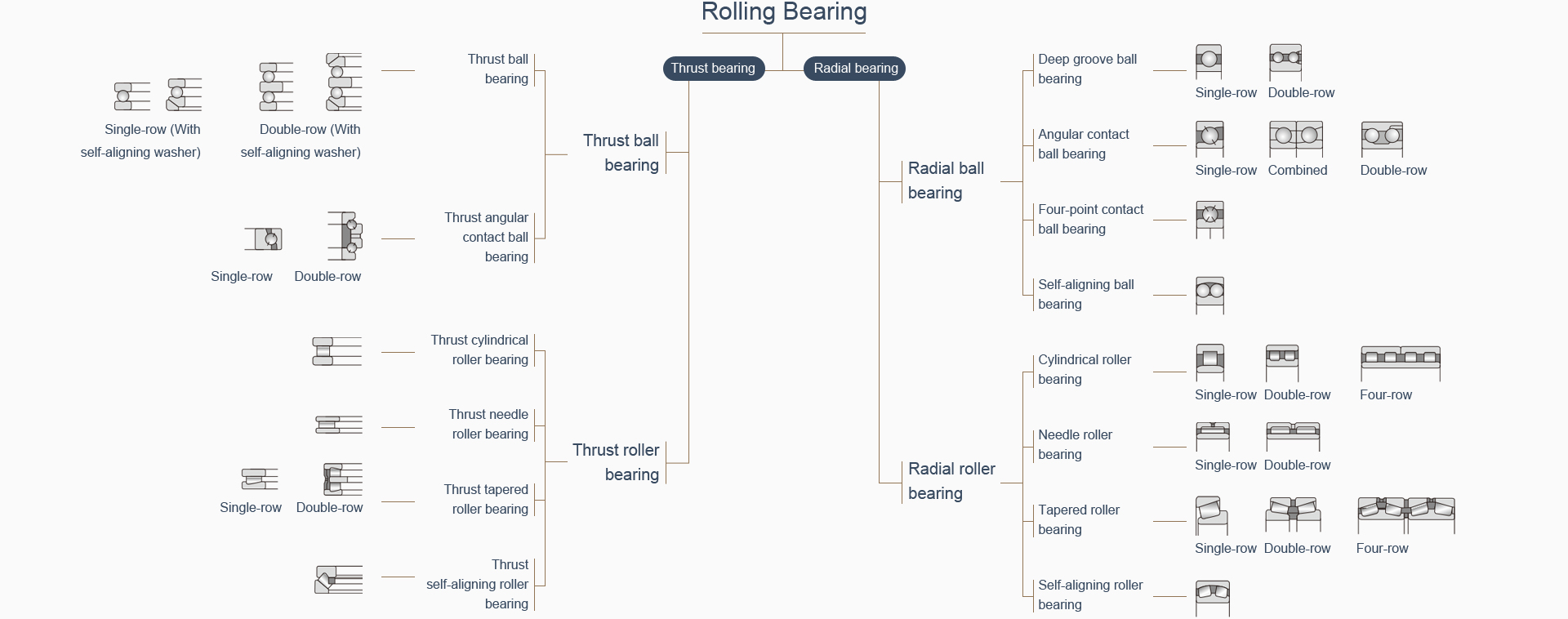

| Bearing Types And Applications | 卖方: DLAIAN GUANGYANG BEARING CO., LTD | Bearing Types and Uses Types of ball and roller bearings for sale Ball Bearings Ball bearings ... | |

| Constant Velocity Joint | 卖方: BOYA Precision Industrial Equipments Co.,Ltd | Constant Velocity Joint is the advantage product of BOYA, which is very welcomed by design instit... | |

| CV Joint Bearing For Steel and Non-ferrous Metal Industries | 卖方: BOYA Precision Industrial Equipments Co.,Ltd | The main CV joint bearing is ball cage type, designed and developed BJ, BHJ, BJS, BC, DOJ five ca... | |

| Ball Joint Bearing for Petrochemical Industry | 卖方: BOYA Precision Industrial Equipments Co.,Ltd | Ball Joint Bearingfor Petrochemical Industry BOYA's ball joint shaftare widely used in the field... | |

| Tension Leveler for Galvanizing Line | 卖方: BOYA Precision Industrial Equipments Co.,Ltd | Galvanizing line tension leveler is a continuous stretching bending straightening machine that is... |