EDM Sinking Mold Parts

Die sinking edm aluminum partsconsist of an electrode and the workpiece is submerged in an insulating liquid. The electrode and the workpiece of EDM machine spare parts are connected to a power supply in which the electrode is made according to the required shape. The machine uses the shape of the electrode to erode the inverse shape in the workpiece.

DESCRIPTION OF EDM SINKING

How sinker edm partsWorks

A “bridge” is created between the part and the electrode.

A spark is created.

The spark creates heat.

Plasma is created around the spark that melts the material.

The spark is turned off and the area implodes on itself, removing material.

The dielectric fluid flushes the zone to start again.

ADVANTAGES OF EDM SINKING

Improving Productivity

Having a productive die-sink EDM process is relatively straightforward: Create the correct work environment, use up-to-date technology of making mold spare parts, and eliminate rework.

Generator Technology

The EDM’s generator technology creates sparks while controlling electrode wear and optimizing cutting speeds. On certain die-sinking EDM equipment, the technology manages the electrical current between the fronts and sides of electrodes and controls its delivery to minimize lateral sparking that disrupts effective machining of areas such as the sides of mould cavities. The system allows the electrode to have maximum power in the front of the cavity without destroying or creating oversize gaps on the cavity side walls.

If you need any kinds of precision plastic molding, please contact us, as a professional precision moulding company, Fangling is willing to offer you high quality products.

在线联系供应商

Other supplier products

| Wire Cutting Mold Parts | We are an unparalleled name in offering a wide gamut of precision wire cutting parts. These wire cutting parts are amongst the most desirable and r... | |

| Standard Mold Parts | We provide DIN(Deutsche Industrie Normen) mold standard partsof high quality to our customers. The mold parts are applied to all kinds of mould bas... | |

| Wire Cutting Mold Parts | We are an unparalleled name in offering a wide gamut of wire cutting parts. These spare parts are amongst the most desirable and reliable products ... | |

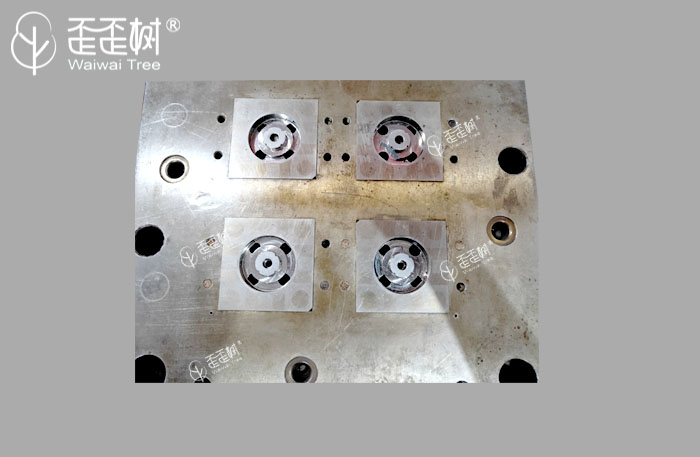

| PRECISION PLASTIC INJECTION MOLDS/TOOLS | When it comes to plastic injection mold parts, precise moulds and precision equipment are required for precision molding or PIM. Among the topics c... | |

| CNC High-Speed Milling Mold Parts | Precision CNC milling parts Completed by CNC milling and forming grinding Accuracy of our custom cnc machining milling partscan be achieved w... |

Same products

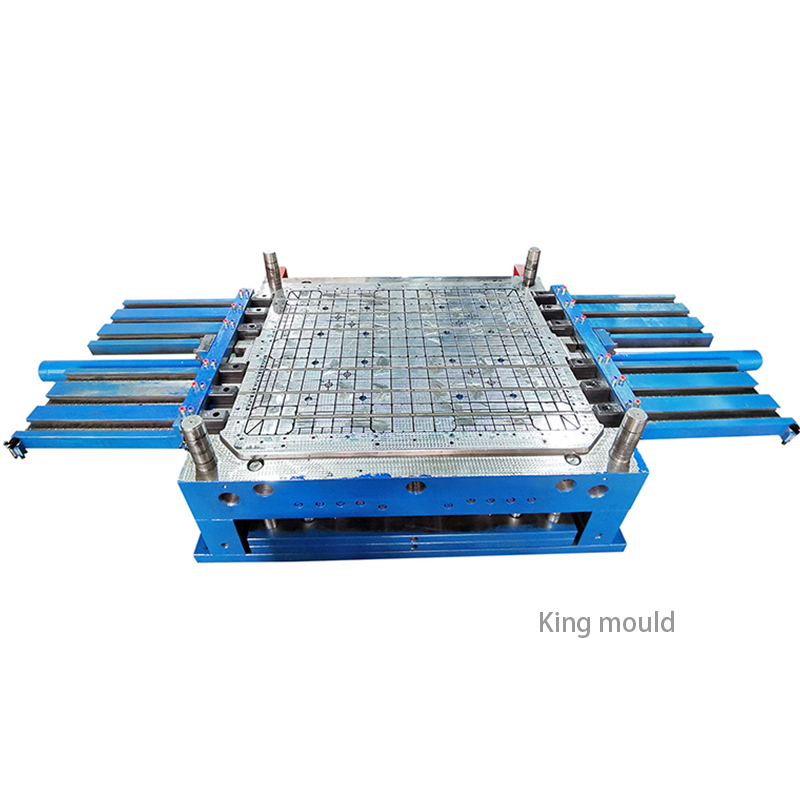

| Plastic Injection Lightweight Pallet Mould | 卖方: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | 卖方: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

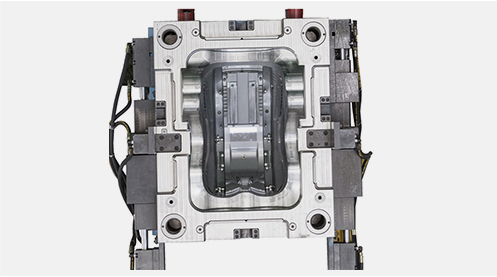

| Injection Mold Manufacturing | 卖方: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | 卖方: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | 卖方: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |