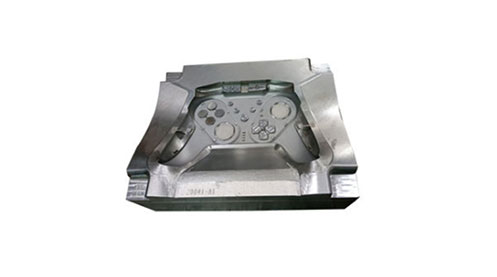

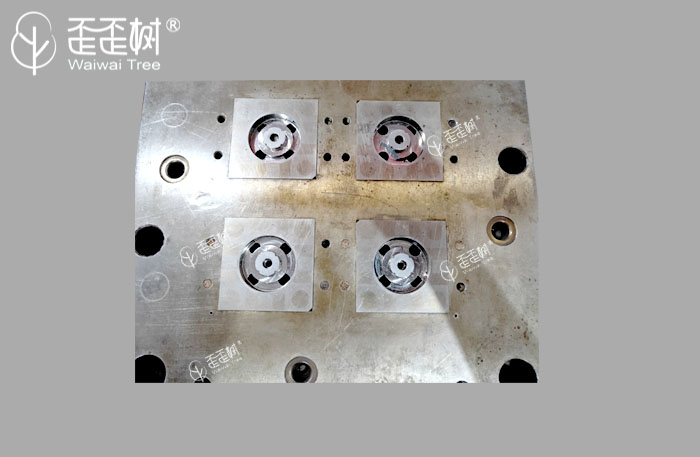

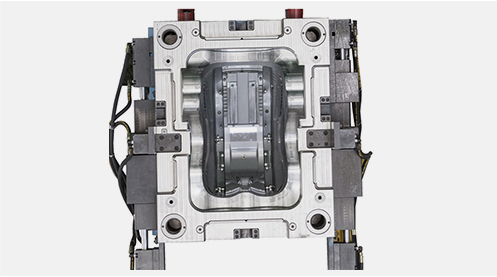

Game Controller Mold

To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time will be saved and the production efficiency increased. Green Vitality concerns a lot on mold cooling system and production stability. Our aim is to make customer run molds as less as possible for mold repair work, the best condition is free of repair work during mass production.

High-quality Game Controller Mould

To produce a high qualifed Gamepad mold, we need to work hard on mold design and analyze injection, ejection and cooling system, so that the gamepad is without flash, sinkmark, deformation and easy demoulding. These are very important factors when making gamepad mold and injection the parts. Some gamepad mold is textured on the surface, while some are glossy. Green Vitality has rich experience in making both textured molds and polished molds. Except mold building, we also provide injection molding, painting, printing, electroplating, ultrasonic welding, assembly service.

Why Choose Us To Make Your Electronic Molds And Molding Parts?

Green Vitality offers a turnkey plastic molding solution from concept ideas to actual products. We make 3d printing, mold design, mold making, parts injection, surface treatment, and post-molding operation services.

State of art mold processing and parts testing equipment.

Professional engineers, technicians, workers, sales, and after-sales teams.

ISO9001:2015 quality control system and modern Japanese management

24hours a day, 7days a week, two shifts working to meet your output demands.

25years experience in plastic injection mold and molding field.

Our motto is Quality is First, Customer is Frist.

For more information about injection molded parts,please feel free to contact us!

在线联系供应商

Other supplier products

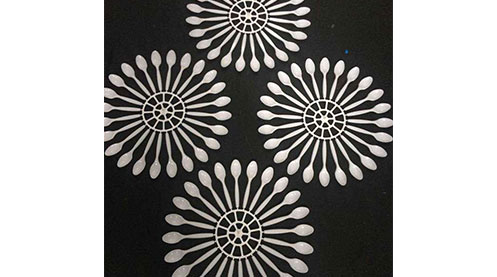

| Plastic Spoon Mould | lastic spoon mainly used for eating, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental protectionso, w... | |

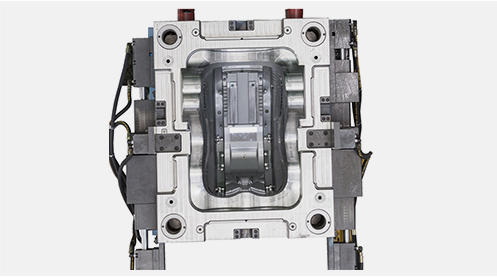

| Industrial Plastic Injection Mold | The injection molding part is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial ... | |

| Teeth Tray Mold | A dental impression is a mold removed from a tooth to diagnose and treat dental conditions. They are also used in forensic science. Impressions are... | |

| Car Seat Mould for Kids | Child safety mouldy car seatsare seats specially designed to protect children from injury or death in a collision. The main structure of the child ... | |

| Filter and Flow Limiting Apparatus | The family mold is used to produce injection parts for liquid filtration and flow monitoring and control systems. These accessories are custom... |

Same products

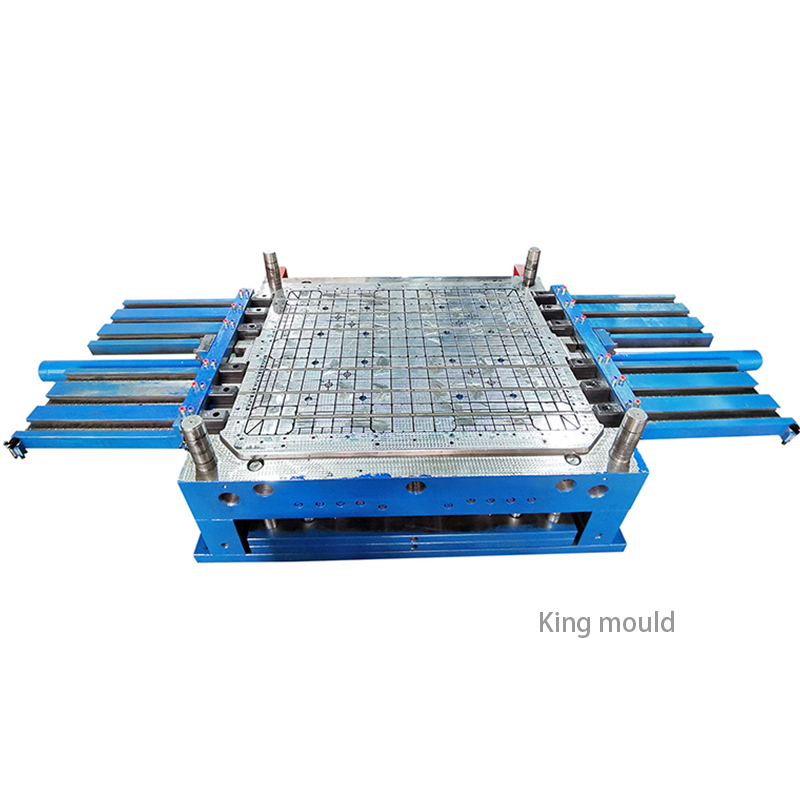

| Plastic Injection Lightweight Pallet Mould | 卖方: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | 卖方: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Injection Mold Manufacturing | 卖方: HANKING MOULD ENGINEERING LTD. | HanKing Mouldhas the advantages of low labor cost, short mold manufacturing lead time, excellent ... | |

| Car Seat Mould for Kids | 卖方: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | 卖方: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |