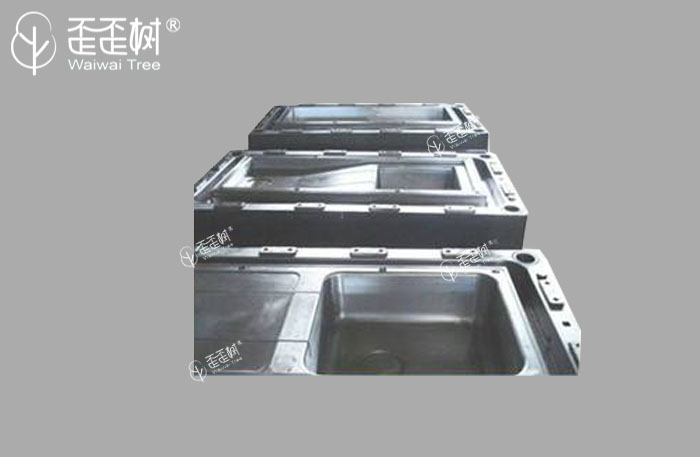

Household Mould

Household Mould Description

Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting surface. The exhaust should be smooth, the position of the discharge, the shape, and the flow of the material should be fully considered, especially for some small ribs. For the movable exhaust, there must be a overflow trough. Vacuuming structure, the mold temperature balance is consistent. The appearance and strength of the product are guaranteed.

Household Mould List

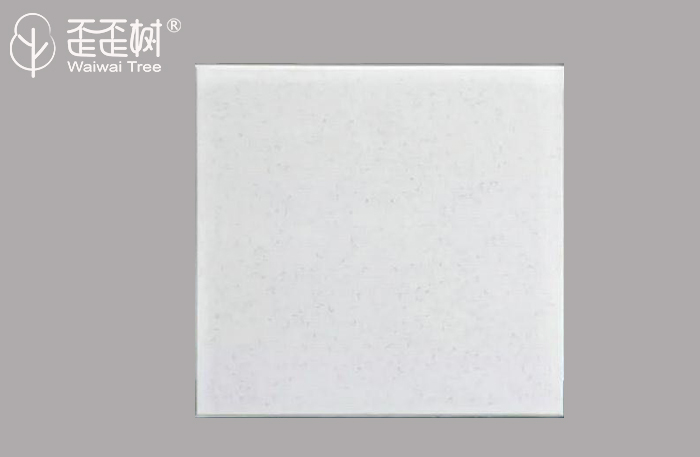

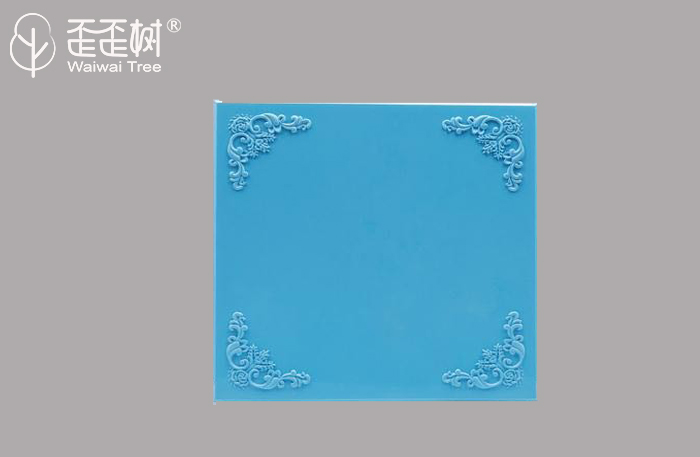

Housing mouldinclude: washbasin mold, laundry basin mold, trash can mold, platen mold, ceiling mold

Household MouldAdvantages

SMC (sheet molding compound) materials are revolutionary materials in the health industry. It is waterproof and does not absorb moisture. It is ultra-light compared to traditional materials used to make sinks or shower trays. SMC materials have a very high strength to weight ratio and are resistant to impact. Compared to acrylic materials, SMC has several times the impact strength. When you drop the SMC shower tray from a height of 1 meter, you won't even break it. It is stain-free and easy to clean. The SMC shower tray provides you with a guaranteed life of more than 30 years.

The advantage is:

High impact strength

High gloss

long lasting

Easy to install, no water leakage in life

Beautiful appearance, no formaldehyde, no harmful substances

High fire performance

acid and alkali resistant

Waterproof and moisture proof

The mold has a high degree of standardization, reasonable flow channel design, small cavity pressure, balanced temperature, no handle, and low power consumption.

Zhejiang Aobang Technology Co., Ltd., established in 2010, is a backbone enterprise that manufactures bmc compositeat home and abroad. We sincerely hope to establish long-term and strong partnership with domestic and foreign businesses and business circles. We hope to gain recognition and support from our customers and to develop mutual cooperation. Just feel free to contact us!

在线联系供应商

Other supplier products

| BMC/SMC Insulation | High-strength, wear-resistant, fire-resistant, color SMC Insulationfor medium and low voltage insulators such as SMC Insulated. Typical application... | |

| BMC/SMC Insulation | BMC Insulation High-strength, wear-resistant, fire-resistant, color BMC compositematerial for medium and low voltage insulators such as SMC Insu... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent p... | |

| BMC, SMC, GRP, GFK Roof Tiles | BMC, SMC, GFK, GRPRoof Tiles BMC, SMC, GFK, GRP roofing materialsare glassfiber reinforced plastic, also known as glassfiber roof, which are compo... | |

| BMC/SMC Insulation | High-strength, wear-resistant, fire-resistant, color BMC material for medium and low voltage insulators such as SMC Insulated. Typical application... |

Same products

| Hose | 卖方: SUZHOU SEAPEAK CO.,LTD | Concrete PU Layflat Hose BUY qualified lay flat concrete pump hose from SEAPEAK! Our lay flat c... | |

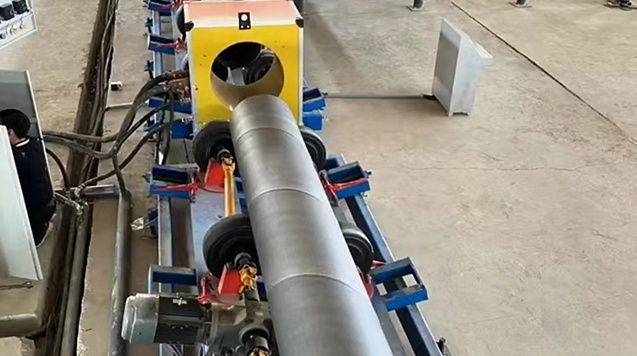

| HIGH FRENQUENCY WELDED STEEL PIPE PRODUCTION LINE | 卖方: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | A high frequency pipe welding machineis a system used for manufacturing steel pipes with high-fre... | |

| ANTI-CORROSION AND INSULATED STEEL PIPE PRODUCTION LINE | 卖方: Hebei tianxianghao metallurgical equipment manufacturing co.,ltd | An anti-corrosion and insulated internal pipe coating equipmentproduction line is a specialized s... | |

| Bronze Globe Valve | 卖方: Zhejiang Carbo Bronze Co., LTD | Bronze Globe Valve Factory The closing component (disc) of a bronze globe valve rotates along th... | |

| Stainless Steel Capillary Tubes | 卖方: WENZHOU HUASHANG STEEL CO.,LTD | Product description Stainless Steel Capillary TubeDescription: Whether you need to exchange d... |