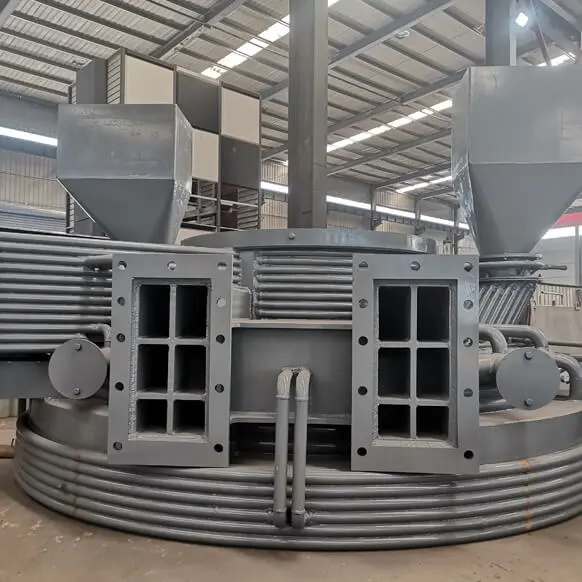

Furnace Auxiliary Equipment

Steelmaking is a continuous process. The meltshop is a hazardous environment, filled with intense heat, suffocating dust, glowing metal, and open flames. Auxiliary machines are equipment or devices that support and facilitate the various processes involved in steel production. These machines play a crucial role in ensuring the efficiency, safety, and quality of the steelmaking process.

TYPES OF FURNACE AUXILIARY EQUIPMENT

The specific auxiliary machines used in a meltshop can vary based on the size of the facility, the steelmaking processes employed, and the level of automation and technology used. Here are some common steel production machinery.

HOW TO ENHANCING STEELMAKING EFFICIENCY AND SAFETY

Crucial Support for Steel Production

Taming the Hazardous Environment

Advancing Innovation and Sustainability

Crucial Support for Steel Production

steel mill equipment for salein the meltshop, including electric arc furnaces and ladle refining furnaces, play a pivotal role in refining raw materials. These machines ensure the quality, composition, and temperature of molten steel, leading to superior end products.

MELTSHOP AUXILIARY MACHINES: ENHANCING PRODUCTION AND ENSURING SAFETY

Meltshop auxiliary machines are vital components within the steel manufacturing process. These machines, ranging from electric arc furnaces and ladle refining equipment to continuous casting machines, play a crucial role in refining raw materials and controlling steel properties. By meticulously managing factors such as composition and temperature, these devices contribute to the production of high-quality end products.

However, the meltshop environment is fraught with hazards, including extreme heat, swirling dust, molten metal, and open flames. Consequently, cooling water systems, dust collection units, and other safety measures are indispensable in minimizing risks and optimizing production processes.

With advancements in technology, innovative steel mill equipmentlike continuous casting systems and vacuum degassing units not only enhance steel quality but also promote sustainable practices by minimizing waste and energy consumption. As stewards of quality and safety, meltshop auxiliary machines remain pivotal in shaping the steel industry's future.

FAQS OF MELTSHOP AUXILIARY MACHINE

HOW DO MELTSHOP AUXILIARY MACHINES CONTRIBUTE TO SUSTAINABILITY?

Innovative auxiliary machines like continuous casting systems and vacuum degassing units contribute to the steel industry's sustainability by reducing waste generation and energy consumption. These machines enhance production efficiency and product quality while minimizing environmental impacts, pushing the industry towards a more environmentally-friendly direction.

WHAT ARE MELTSHOP AUXILIARY MACHINES?

Meltshop auxiliary machines are machinery and equipment that support and facilitate various processes in the steel production industry. They include electric arc furnaces, continuous casting machines, vacuum degassing units, among others. These machines optimize steel production processes, improve product quality, and ensure employee safety.

WHAT ROLES DO THESE MACHINES PLAY IN THE STEELMAKING PROCESS?

Meltshop steel manufacturing machineryplay crucial roles in refining raw materials, adjusting alloy compositions, and controlling steel temperature. For instance, electric arc furnaces melt scrap metal, continuous casting machines shape molten steel into continuous billets, and vacuum degassing units remove gas impurities from the molten steel.

IS THE ENVIRONMENT IN THE MELTSHOP HAZARDOUS?

Yes, the meltshop environment is filled with high temperatures, molten metal, swirling dust, and open flames. These factors pose potential risks and hazards to workers. Thus, equipment like cooling water systems and dust collection units are crucial for ensuring safety in the workplace.

There are many steel mill equipment manufacturers, but we are one of the best choices for you.

For more informationabout steel making machine priceand steel machinery manufacturing, please feel free to contact us!

Contact us to buy furnace in metallurgy.

在线联系供应商

Other supplier products

| OXYGEN LANCE MANIPULATOR | The carbon oxygen lance mainly refers to the EAF smelting, generally referring to the carbon oxygen lance at the EAF furnace door, as well as the f... | |

| LADLE FURNACE ROOFING | LF roofing is round-shaped and has a tube-type water-cooled structure. It is divided into a large furnace roof, a small ramming roof, an offgas exh... | |

| WATER COOLED CABLE | WATER COOLED CABLE Large cross-section water cooled power cablesare used for the connection between the busbar system and the EAF arm, transmittin... | |

| SLAG POT | Both ferrous and non-ferrous metallurgical enterprises produce a large amount of high-temperature liquid slag, and the vast majority of steel furna... | |

| LADLE PRE-HEATER | ladle pre heaterare suitable for different types of gas or liquid fuels. Such as blast furnace gas, mixed gas, natural gas, propane, acetylene, etc... |

Same products

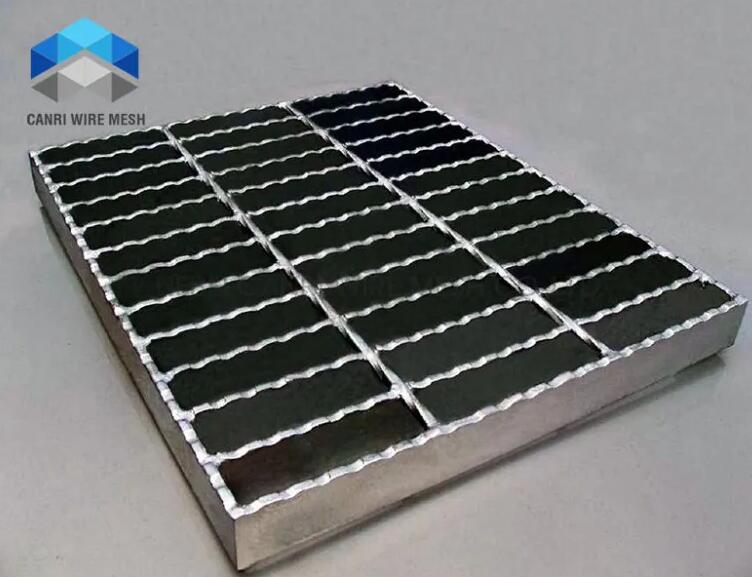

| Galvanized Steel Grating for Drainage | 卖方: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |