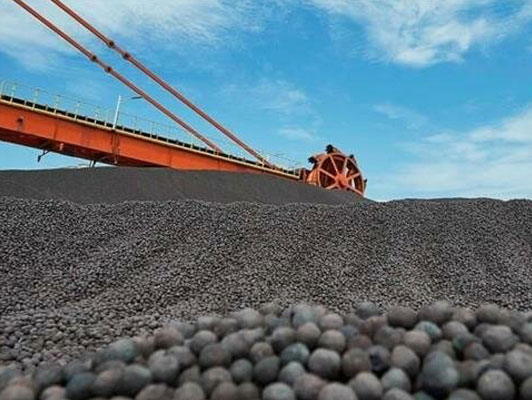

Direct Reduced Iron (DRI Steel)

Description of Direct Reduced Iron (DRI in Steel Plant)

Direct reduced iron (DRI), also called DRI sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) to iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suitable for making direct reduction iron.

Direct reduction refers to solid-state processes that reduce iron oxides to metallic iron at temperatures below the melting point of iron. Reduced iron derives its name from these processes, one example being heating iron ore in a furnace at a high temperature of 800 to 1,200 °C in the presence of the reducing gas syngas, a mixture of hydrogen and carbon monoxide. DRI direct reduced iron, is produced through the removal (reduction) of oxygen from iron ore in its solid-state. This technology encompasses various processes based on different feedstocks, reactors, and reducing agents. DRI processes can reduce CO2 emissions by using natural gas instead of coal due to the replacement of carbon reductant by hydrogen from methane.

Basic characteristics of Direct reduced iron (DRI)

1. Stable chemical composition can effectively dilute the residuals and metal elements in steel thus improve the steel quality.

2. Low content of harmful elements, such as P and s and it can shorten refining time.

3. Reduce the loading times, power cut operation and heat loss. Fast melting speed and low power consumption can improve efficiency and reduce cost.

4. During the melting period, with a stable electricity supply, high power supply is allowed.

5. Low cost and high economic benefit.

Direct Reduction Iron Process / Direct Reduced Iron Process

Indirect reduction plant, the oxide pellets produces in the pelletizing plant enters the reduction plant from the top into the furnace after it has had its chemical and physical properties checked, and loses its oxygen to the reducing gas which flows upwards from the bottom of the module.H2 and CO and H2O is the initial mixture of the reducing gas with the radio of 1.5 to 1.7. This mixture absorbs the oxygen content of the pellets and changes into CO2 and H2O and gets out of the furnace from the top.

As a direct reduction iron company, we will do our best to meet all the needs of customers.

HUARO offers high-quality steel product, steel raw material and other raw material. We depend on Huaruo worldwide supply chain to introduce and export our superior products.

We can also offer sorts of steel billets for sale, if you have needs, please contact us.

Other supplier products

|

|

Hot Rolled Strip |

Description of Hot Rolled Steel Strip

Hot Rolled Steel Strip generally refers to a coiled steel strip having a thickness of 1 to 20 mm, and the wid... |

|

|

Hot Rolled Strip |

Description of Hot Rolled Steel Strip

Hot rolled stripgenerally refers to a coiled steel strip having a thickness of 1 to 20 mm, and the width is ... |

|

|

Steel Making Raw Material |

Description of Steel Raw Material

Steel is one kind of alloy, made of iron and carbon. The carbon content is usually less than two percent and for... |

|

|

Prepainted Galvanized Steel Coil |

General Description of Prepainted Galvanized Steel Coil

Pre-coated coil is a product obtained by chemical surface treatment (coating) of hot-dippe... |

|

|

Hot Rolled Strip |

Description of Hot Rolled Steel Strip

Hot Rolled Stripgenerally refers to a coiled steel strip having a thickness of 1 to 20 mm, and the width is ... |

供应产品

Same products