Hot Rolled Steel Coil

Description of Hot Rolled Steel Coil

Hot rolling is a mill process that involves rolling the steel at a high temperature (typically at a temperature over 1700° F), which is above the steel’s recrystallization temperature. When steel is above the recrystallization temperature, it can be shaped and formed easily, and the steel can be made in much larger sizes. As one of the professional hot rolled coil suppliers and cold rolled steel coil manufacturers , HUARO offers high-quality hot rolled steel coil and cold rolled steel coil for sale, come and buy hot rolled steel coil at HUARO.

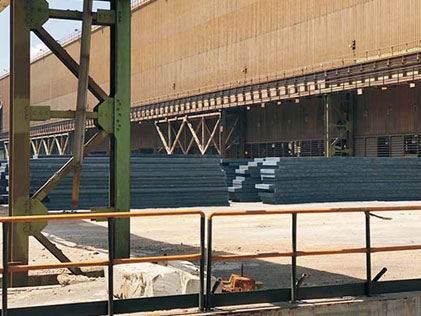

As we all know, the steel slab is made from the continuous casting machine after the steel pellets melted in the EAF furnace and the removal of the impurities. The production of hot rolled steel coil is the first procedure for the steel slab. After the first mill and finish mill, the thickness will reduce and finally get the hot rolled steel sheet in coil.

HRC Main Feature and Production Process

Hot steel coils production is a rolling process that involves rolling steel at high temperatures (usually above 1700°F) above the recrystallization temperature of steel. When the steel is higher than the recrystallization temperature, it can be formed and shaped easily, and the steel can be made to larger sizes. Hot rolled steel is usually cheaper than cold rolled steel because of the fact that it is usually manufactured without any delays and then does not require reheating of the steel (as with cold rolling). As steel cools, it contracts slightly compared to cold rolling, so there is less control over the size and shape of the finished product.

The Advantage of Hot Rolled Steel Coil

The hot rolled coil as known as HRC. The slabs are heated in a natural gas-fired furnace before processing it through a hot rolling mill. This process reduces the thickness. Once it is cooled, the plate is cut into the desired length and the coil is further processed through the cold rolling mills. HUARO Steel offers a range of Hot Rolled Coils with diverse specifications. All our products meet international standards. They fulfill a wide range of market needs like deep drawing, bending, laser cutting, welding, and forming. As a hot rolled steel coil manufacturer / hot rolled steel coil factory / hot rolled steel sheet factory, we offer the Hot Rolled Coils in the form of coils and cut to length sheets.

Application of Hot Rolled Steel Coil

Commercial steel like steel commercial tubes, general fabrications, steel sheets, and corrugated steel.

Structural steel for the electrical industry.

For sour and non-sour applications in oil and gas pipelines as well as water pipelines.

Gas cylinders and presser vessel tanks.

Carton steel can be used for atmosphere corrosion applications like open steel containers.

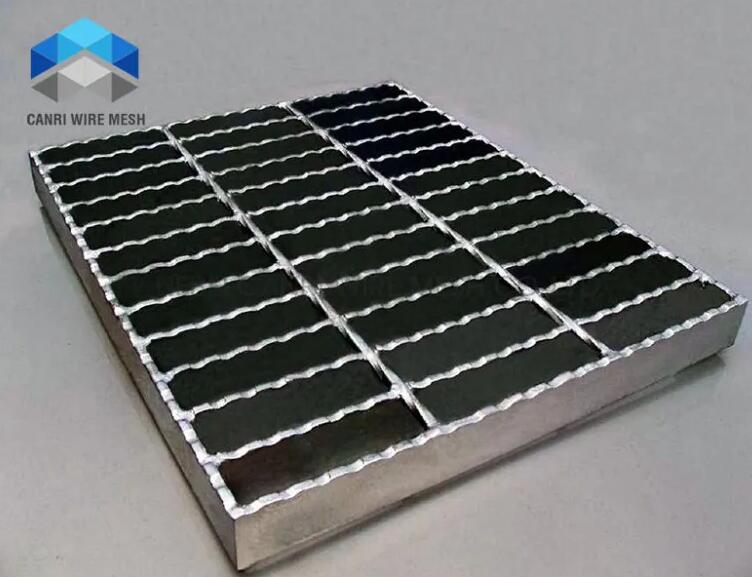

The Chequered form of Hot Rolled Coils can be used for Anti-slip applications like floors.

Other supplier products

|

|

Cold Rolled Coil |

Description ofCold Rolled Coil

Cold rolled coil, as known as CR coil, CRS or CRC. Cold rolled steel coils are a farther product that uses hot roll... |

|

|

Galvanized Steel Coils |

Description of Galvanized Steel Coils Hot-dip galvanized steel coils are produced by passing the acid-washed and calendered full hard plate through... |

|

|

Steel Product |

Importance of steel products list

Steel is one of the oldest metals forged by humans and is still the most reliable and widely used material in ma... |

|

|

Graphite Electrode |

Definition of Huaro Graphite Electrode Graphite electrode is high temperature resistant graphite conductive material. It is made of petroleum coke ... |

|

|

Pickled Coils |

Description of Pickled Coils

Pickling is a production procedure to remove the oxide scale on the cold rolled steel coil surface during steelmaking.... |

供应产品

Same products