WATER-COOLED PANELS

CHNZBTECH, a professional water cooled panelssupplier, is committed to getting those standards, engineering and manufacturing water-cooled panels and equipment at our own facilities, especially for EAF, LF, and SAF, so as to achieve the high-quality standards now expected by steel furnace manufacturers.

Because the major causes of unscheduled downtimes in steel plant production are also failures of water-cooled panels a plant's availability index is increased significantly when CHNZBTECH's high-efficiency and high-reliability water-cooled components are mounted. This performance is reached by continuous quality monitoring of our standard manufacturing procedures and materials (boiler type / low-carbon steel tubes, copper tubes), assembling and welding procedures, and pre-delivery tests. All this is provided, together with the on-time delivery company policy.

FEATURES

CHNZBTECH WATER-COOLED PANELS FEATURES

EAF, LF SAF Steel and copper panels

EAF shell sidewall panels

LF/EAF roof panels

VD/VOD water-cooled shield

Fume-treatment plant water-cooled duct (primary water-cooling system).

CHNZBTECH strength:

Standard EAF shell panels: 4000 heats

Roof panels: 5,000 heats

Long-life energy saving panels: more than 11x`,000 heats

DESCRIPTIONS

WATER-COOLED PANELS DESCRIPTIONS

A water cooling panel forms a part of or substitute for the wall of a metallurgical furnace, such as an electric arc furnace, LF furnace, VOD, AOD furnace. These industrial furnace parts can be formed alternately as tube type coolers formed of parallel pipes connected at its ends in headers, with the latter having internal baffles to define a serpentine path, or as box type coolers formed of steel plates or sheet and having internal baffle plates defining a serpentine path for the cooling fluid. In either case, fluid orificies are provided to permit a minor amount of flow through the baffles or baffle plates where there is a direction change in the serpentine flow path. This serves to prevent stagnation and prevent the problems of hot spots and steam bubbles where there is a change of direction in the cooling flow. Projections welded along the furnace-facing side of the panel permit the panel to be covered with a layer of refractory material or solidified slag.

在线联系供应商

Other supplier products

| OXYGEN LANCE MANIPULATOR | The carbon-oxygen lance mainly refers to the EAF smelting, generally referring to the carbon-oxygen lance at the EAF furnace door, as well as the f... | |

| Submerged ARC Furnace | The saf submerged arc furnace(SAF) is a specialized heating system utilized to produce a range of iron alloys using electric power. The smelting pr... | |

| OXYGEN LANCE MANIPULATOR | The carbon oxygen lance mainly refers to the EAF smelting, generally referring to the carbon oxygen lance at the EAF furnace door, as well as the f... | |

| TOP CHARGING ELECTRIC ARC FURNACE | TOP CHARGING ELECTRIC ARC FURNACE Top EAF chargingis convention type, from 0.5t to 200t, each capacity requires a bucket charge from the top. The ... | |

| SCRAP BUCKET | In steelmaking equipment, the scrap bucketis a device for loading scrap steel, used to inject scrap steel into the steelmaking furnace. The steel b... |

Same products

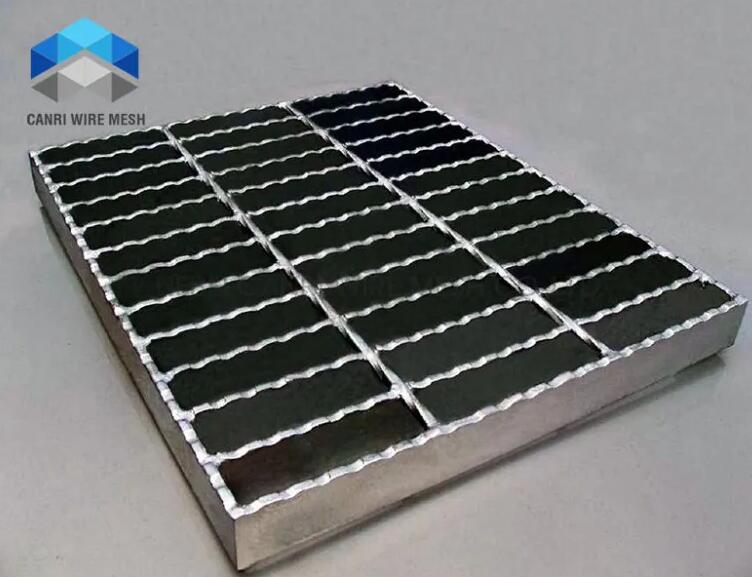

| Galvanized Steel Grating for Drainage | 卖方: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... | |

| Galvanized Steel Grating | 卖方: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating Galvanized steel gratingis an ideal product for wet, slippery situation... |