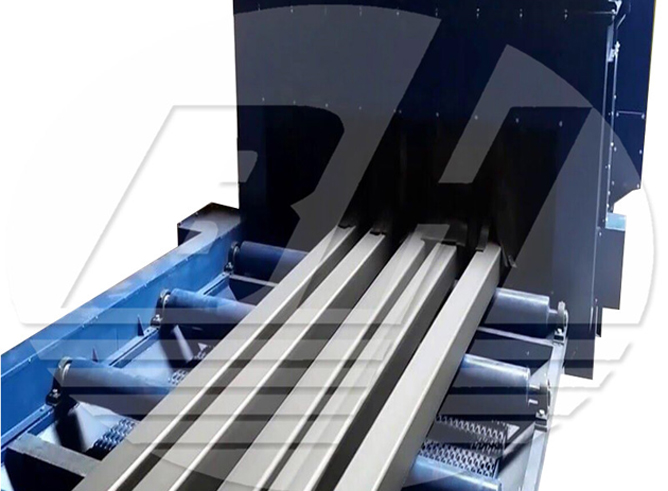

Steel Structure Shot Blasting Machine

Steel Shot Blasting Equipmentis built to clean profiles welded, pipes, H-Beam and I Beam, and other similar workpieces. It strongly blasts different kinds of shaped steel metal profiles to remove surface rust, welding slag and scale, making it slow uniform metal color, improve coating quality and corrosion prevention effect.

Advantages of Steel Ball BlastingMachine

The steel is hoisted into the feeding roller table and sent to the closing shot blasting cleaning room by the roller table conveyor system. The impeller rotating at high speed is used to accelerate the steel wire shot (Abrasive) to the surface of the workpiece and impact the surface of the workpiece, scraping to remove the rust and dirt on the surface of the workpiece, and then use the roller brush, the collecting screw and the high-pressure blowpipe to clean the accumulated particles and floating dust on the surface of the workpiece, and then it is sent out of the purge chamber by the roller conveyor system to the delivery roller. Then transport it to the designated unloading rack via forklift or crane.

Features of Steel Shot Machine

Workpiece detection device, effectively control the opening and stopping time of the shot blasting machine, avoid the emptying of the steel shot blaster, save energy, and improve the lives of the wearing parts such as the room guard plate and the shot blasting machine.

This machine is equipped with functions such as automatic fault detection and alarm, and automatic stop after the delay.

Dust removal system adopts high-efficiency filter drum dust collector, the dust emission is within 100mg / m3, and the workshop dust emission is within 10mg / m3, which greatly improves the worker's operating environment.

The bearing protection at both ends of the elevator, separator, and screw conveyor adopts a labyrinth sealing device and a U-shaped boss structure. The separation screw and screw conveyor discharge ports are arranged at a distance from the end, and at the end of the screw Add reverse conveying blades.

The hoist adopts special polyester wire core hoist transmission belt, and the upper and lower reels of the hoist adopt chambered squirrel cage structure, which not only increases friction to avoid slipping, but also prevents scratching of the belt. Each power point of the Abrasive circulation system is provided with a fault alarm function.

The large nut fixed by our company adopts cast special iron nut, its structure and the contact surface of the protective plate are larger, and it is more effective to prevent the broken ring caused by the Abrasive entering the shell due to the loosening of the nut.

Abrasive cleaning: in order to meet the requirements of higher production efficiency, we use abrasive cleaning.

First-level cleaning: high-strength nylon roller brush + pill collecting screw; cleaning brush life ≥5400h

Secondary air blowing: high-pressure fan blows shots and blows dust inside and outside the cleaning chamber to ensure that there are no shots on the surface when the steel plate is cleaned out of the cleaning room.

The abrasive circulation purification system is composed of a circulation system and a separation and purification system. These two parts are further divided into a pill silo, a sliding tube, an abrasive controller, (shot blaster,) screw conveyor, a bucket elevator, a separator, etc. The system's abrasive controller, screw conveyor, bucket elevator and pellet separator are interlocked in the electronic control system: the post-process does not work, and the pre-process cannot run, thus avoiding equipment failure due to abrasive blockage.

Roller drive adopts step-less frequency conversion speed regulation (using a frequency converter, the manufacturer is generally Mitsubishi, can also be specified), instead of speed regulation motor, the entire workpiece conveying system frequency conversion step-less speed regulation. (Speed range 0.5-4m / min)

Input, output and segmented transmission of the chamber roller table, step-less speed regulation, that is, it can run synchronously with the entire line, and can also run quickly, so that the steel can quickly travel to the work position or quickly exit to the discharge station purpose.

Adopt full line PLC programmable controller power, automatic detection and automatic search for fault point, sound and light alarm.

The equipment has a compact structure, a reasonable layout, and is very convenient for maintenance.

Roller cleaning

The roller brush cleaning system is equipped with a high-elastic nylon roller brush, a pill screw conveyor and its lifting mechanism. The high-strength nylon roller brush sweeps the projectiles during the rotation and sweeps them into the pill-receiving screw conveyor, and then the pill-receiving screw conveyors discharge the projectiles into the chamber and are taken away by the bottom of the shot blasting machine. Among them, the key component nylon roller brush has the following advantages: The composite nylon material with high elasticity Φ3mm is used, the hardness is moderate, the elasticity is large, the wear resistance is good, the bristles are firmly clamped, and the special tooling is used to stamp the bristles into blocks, and the bristles are not lost in the work. After the entire nylon roller brush is installed, the precision axle head guarantees the coaxiality. Good dynamic balance and stable work.

Working Principe of Steel Structure Shot Blasting Machine

The steel is hoisted into the feeding roller table and sent to the closing shot blasting cleaning room by the roller table conveyor system. The impeller rotating at high speed is used to accelerate the steel wire shot (Abrasive) to the surface of the workpiece and impact the surface of the workpiece, Scraping to remove the rust and dirt on the surface of the workpiece, and then use the roller brush, the collecting screw and the high-pressure blowpipe to clean the accumulated particles and floating dust on the surface of the workpiece, and then it is sent out of the purge chamber by the roller conveyor system to the delivery roller Then transport it to the designated unloading rack via forklift or crane. We have steel shot blaster for sale, welcome to buy our steel grit blasting equipment.

As the shot blasting equipment suppliers, Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. It is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. Sand blasting Machines clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on.

在线联系供应商

Other supplier products

| Shot Blasting | BH has a variety of parts and blasting equipment for sale and our customers are from all over the world. More than 2000 active customers domestic a... | |

| Tumble Steel Belt Shot Blasting Machine | This crawler shot blasting machineis one of the standard series of cleaning equipment. It can be used to clean casting, forging and welding parts, ... | |

| QXY Steel Plate Pretreatment Line | QXY Steel Plate preservation line is mainly used for surface treatment (namely preheating, rust removal, paint spraying and drying) of the steel pl... | |

| Steel Pipe Shot Blasting Machine | Steel pipe shot blasting machineis a new type of special shot blasting equipment designed to user requirements, which is specially used for cleanin... | |

| Shot Blasting Room | Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cind... |

Same products

| AEMK 588 Loader | 卖方: 烟台欣祥国际贸易有限公司 | 驾驶室高度:2670毫米 整车尺寸(长*宽*高):5700*2000*2670毫米 前轮配重:4250毫米 轴距:2500毫米 离地间隙:480毫米 最大卸料高度:3500毫米 最大... | |

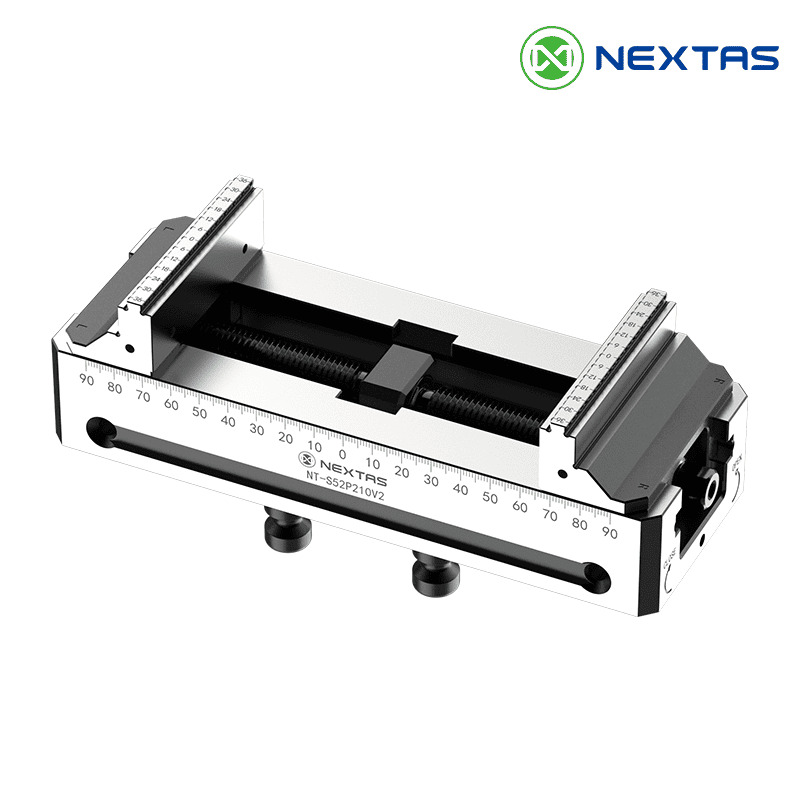

| Quick Change Worktable | 卖方: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

| Self Centering Vise | 卖方: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | 卖方: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | 卖方: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |