HIGH-QUALITY ROLL FORMING MACHINE FOR YOU

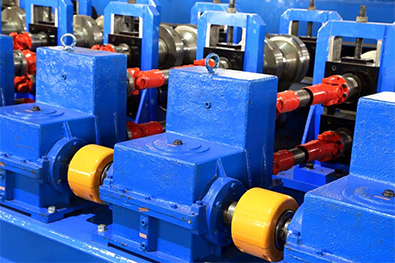

Roll Design and Manufacturing Features of Automatic Cold Roll Forming Machine, uprightrollformingmachine:

Each roller power for each roller is average, total production line is stressed, the wear is balanced, and the service life of the roll is extended.

Roller material good material is to use its wear resistance, but the specific strength and hardness are contradictory, the red hardness should be utilized during heat treatment, and the hardness can be achieved after two or even three times of tempering after quenching.

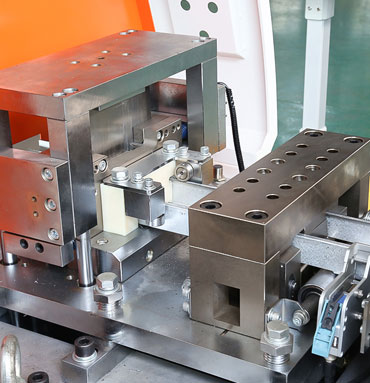

The arc part of the track is the core part of the slide rail. The arc position of the first few passes after the press forming, in the subsequent pass rolling the vertical edge, the formed arc should be formed, and the effective tube bundle protection is carried out by the upper and lower rolls or the horizontal wheel.

Otherwise, the arc position of the material will change during the stretching process, R becomes smaller and becomes a triangle, the steel ball is not in the end, the two points contact the noise, and when the R becomes large, the coordination rail is swayed, and the track is blurred when used. Uneven force, deformation of the slide rail and shortened life.

How to solve the stability problem when using the roll forming equipment?

Rolling stability problem, the production often encounters the problem of material yaw in the raceway, in fact, the single set of rollers is asymmetrical, the left side is strong, the material is yaw to the right; the right side is strong, the material Deflection to the left.

We have corrugated roll former for sale, the pop channel machine priceof our company is affordable,If you need, please contact us in time.

BOSJ estabilished in 2004, As a leading producer of many types of china cold roll forming machine, BOSJ has won worldwide reputation in this field. Our products have broad markets in Southeast Asia, India, North and South America,Western Asia, Russia and Australia. We guarantee first-rate after-sale service and product quality. Establishing abiding friendship with any customers interested in roll forming machines is our goal. Sincerely, we invite you to pay a visit to our company.

在线联系供应商

Other supplier products

| SHEET ROLL FORMING MACHINE | BOSJ steelsheetrollformingmachinehave a reasonable design structure, beautiful appearance, convenient operation, adjustment and maintenance. The fu... | |

| Profile Roll Forming Machine | In the BOSJ Plant, you will get an exciting look behind the scenes of china cold roll forming machineparts manufacturing and installation. The tour... | |

| STEEL SILO ROLL FORMING MACHINE | BOSJ develops and produces auxiliary equipment such as metal granary, steel silo, water tank line and supporting ladder, upper and lower vertebra, ... | |

| BILLET COMPRESSOR WHEELE | The impeller of billet compressor consists of hub, blade and cover. The cover of the submerged pump impeller and the rear cover are divided. The co... | |

| Standing Tube Cutting Machine | Main Function It is mainly used in tube cutting. Basic Parameter Length:0.6~3m Tube diameter:¢33m、¢48mm and ¢60mm Length tolerance:≤0.5mm BOSJ e... |

Same products

| Cable Pulling Sock | 卖方: 00000 | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | 卖方: 00000 | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | 卖方: 00000 | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | 卖方: 00000 | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | 卖方: 00000 | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |