LARGE DIAMETER SPIRAL PIPE MILL

A spiral pipe mill machineis used to roll the low carbon steel/ low alloy steel strip into a tube by a certain forming angle and further weld it into a steel pipe by submerged arc welder. With the assistance of our spiral tube forming machines, large diameter pipes can be produced with a narrow steel strip.

We are your reliable China spiral welded pipe factory. If you are looking for spiral pipe making machine for spiral welded steel pipe, don't hesitate to contact us. As one of the professional spiral pipe manufacturers in China, Hangzhou Roll Forming Technology sells welded tube mills at reasonable prices.

Large Diameter Spiral Pipe Mill Technical Parameters

|

Model |

Specification |

Coil Width |

Thickness |

Coil Weight |

Capacity(Kw) |

Area |

|

(mm) |

(mm) |

(mm) |

(ton) |

(Estimate M) |

||

|

RFT-426 |

Φ219~Φ426 |

400~750 |

5~8 |

10 |

200 |

20×96 |

|

RFT-529 |

Φ219~Φ529 |

400~800 |

5~10 |

15 |

300 |

20×96 |

|

RFT-630 |

Φ219~Φ630 |

450~1050 |

5~12.7 |

15 |

400 |

20×96 |

|

RFT-720 |

Φ219~Φ720 |

500~1250 |

5~12.7 |

15 |

500 |

24×108 |

|

RFT-820 |

Φ219~Φ820 |

500~1300 |

6~12.7 |

20 |

500 |

24×108 |

|

RFT-1020 |

Φ219~Φ1020 |

500~1300 |

6~12.7 |

20 |

800 |

24×108 |

|

RFT-1420 |

Φ325~Φ1420 |

500~1560 |

6~18 |

30 |

1000 |

26×126 |

|

RFT-1620 |

Φ426~Φ1620 |

500~1560 |

6~20 |

30 |

1500 |

26×126 |

|

RFT-1820 |

Φ508~Φ1820 |

1100~1600 |

8~25.4 |

30 |

1500 |

30×180 |

|

RFT-2020 |

Φ508~Φ2020 |

1200~2000 |

8~25.4 |

40 |

1500 |

30×180 |

|

RFT-2400 |

Φ508~Φ2400 |

1200~2000 |

8~25.4 |

40 |

1800 |

30×180 |

|

RFT-3000 |

Φ508~Φ3000 |

1200~2000 |

8~25.4 |

40 |

1800 |

30×180 |

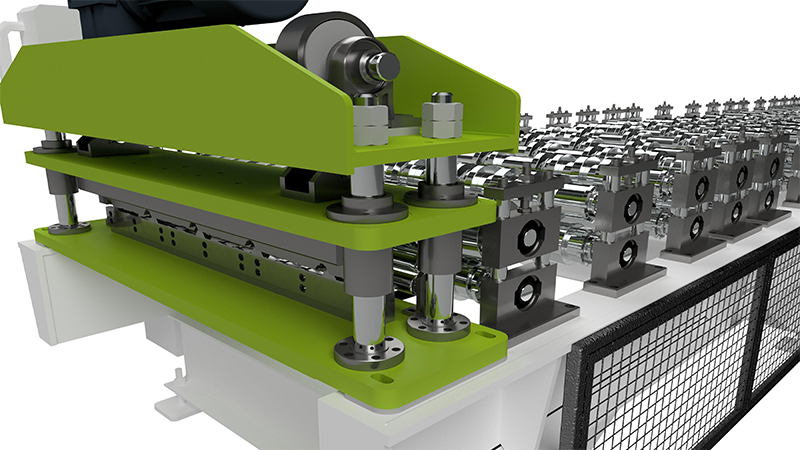

Main Equipment Components of spiral welded pipe making machine

Decoiler

Pinching & leveling machine

Manual/Electrical roll

End - Cutting & butt-welding machine

Rotary shear

Delivery machine

Guide board

Forming unit

Front bridge

Inside/outside welding device

Rear bridge

Flying saw cutter

Buried parts

Hydraulic system

Electric system

Inside/outside welder

Butt-weld car

Plasma cutter

Weld flux processing device

Beveling & end-facing machine

Hydraulic tester

Finishing equipment

Working Flow of Large Diameter steel welding pipe forming machine

Large Diameter Spiral Welded Steel Pipe Applications

For liquid delivery: water supply& drainage;

For gas delivery: coal gas, steam, and LPG;

For structural use: piling pipe, structural pipe in the field of bridge, dock, road, and construction, etc.

Finished large diameter spiral welded steel pipeby Spiral Tube Forming Machine

Specification of Spiral Pipe Making Machine

|

Machine Condition |

Fully New, A-Grade quality |

|

Size |

As requests |

|

Power Supply |

220V/380V/415V/460V/480V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 30ton-300ton |

|

Dimension |

40m–400m (length) x 3.8m-40m (width) |

|

LOADING SIZE |

Normally need 4-30 x 40' containers |

|

Equipment Color |

normally Blue/Green/White, or as requests |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

HZrollforming, as a professional tube mill manufacturer, offers a wide range of tube roll forming machinefor you to choose from.

在线联系供应商

Other supplier products

| AG Panel Roll Former | This AG panel roll forming machineseries is used to make high-quality AG panels. As a professional roof and wall panel roll forming machine manufac... | |

| API PIPE MILL FOR OIL TRANSPORTATION | API Pipe MillFor Oil Transportation is a series of machines that build longitudinal weld seam tubes and pipes with steel strips of certain width. ... | |

| High Speed Roofing Tile Making Machine | The high-speed roofing tile machinesis for continuously roll forming and pressing step tilessheets. Thesteplength of this series can be set up andt... | |

| CABLE TRAY ROLL FORMING MACHINE | Well designed by engineers at Hangzhou Roll Forming Technology, this series of cable punching machines can produce cable trays and caps from 50-350... | |

| Double Layer Roll Forming Machine | Double layer cold roll forming machine, also called double deck roll forming machine. To meet the requirements for roll forming two different profi... |

Same products

| Cable Pulling Sock | 卖方: 00000 | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | 卖方: 00000 | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | 卖方: 00000 | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | 卖方: 00000 | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | 卖方: 00000 | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |