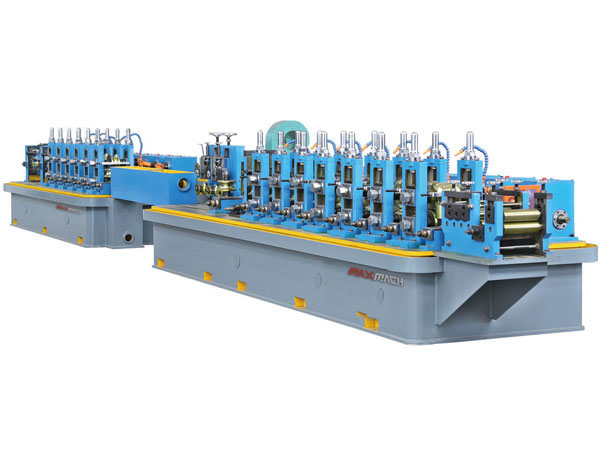

Maxtube 50 Welded Pipe Making Machine

Description

Welded pipe making machine is the main equipment for the welded tube production line. It is designed to form pipes and tubes on one continuous line with steel strip, which is slit by slitting line to fit diameter of pipe and tube. Our Maxtube 50 tube mill line is specially designed to produce Φ15-Φ63.5 mm and δ0.8-2.5 mm high-frequency straight seam welded tube, square tube and special-shaped tube (δ≤2.0mm). In addition, we can produce as per customers’ requirements.

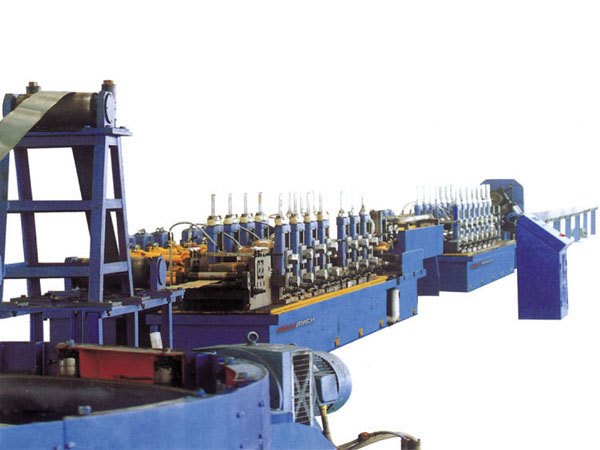

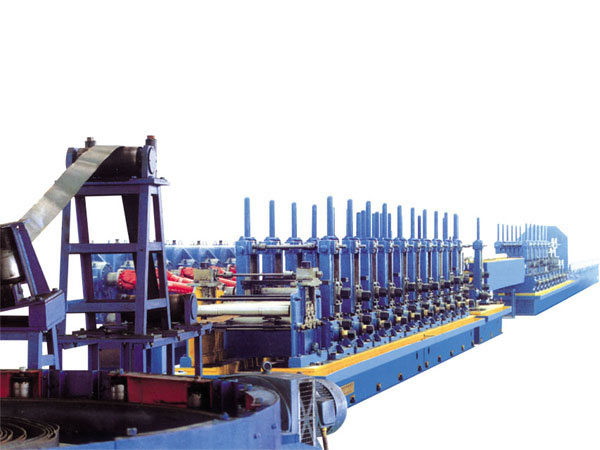

Working principle of welded pipe making machine

Hydraulic cylinder of strip feeding unit holds down steel strip. The feeding motor drives the feeding roll to fill strip into the accumulator by friction force. The main motor rotates supply roll of the accumulator cage to store steel strip in inner and outer storage area. The drive motor stops after one coil finishes and continues feeding after cutting and welding another coil.

Features

- 2.Our welded pipe making machine is with long working life. 3.All of our products are with excellent performance at low cost. 4. By absorbing advanced pipe making technology from domestic and overseas, our products are both economical and practical.

Technical specifications of welded pipe making machine

|

Description |

Maxtube 50 tube mill line |

|

Diameter of welded tubes |

Φ15-63.5mm |

|

Wall thickness of welded tubes |

|

|

Speed of tube welding |

40-80M/min |

|

Power of major motor) |

110KW |

|

Power of high frequency welder |

150KW |

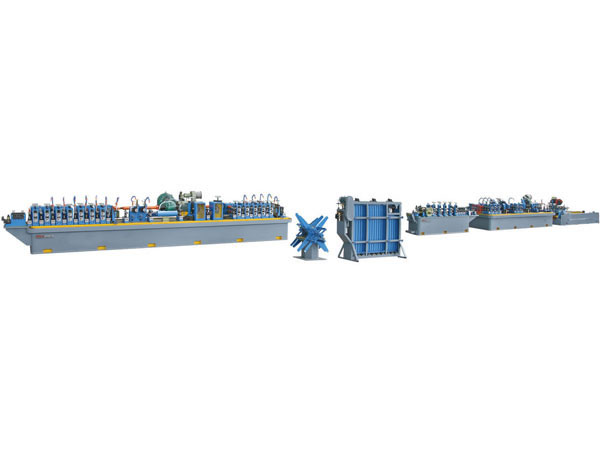

Basic components for Maxtube 50 welded pipe making machine

- Uncoiler→ Shearing and butt-welder →Vertical-type accumulator → Forming machine →Water cooling tank →Sizing machine→ Computer cutting saw →Run-out table 2. Hydraulic uncoiler →Shearing and butt-welder →Horizontal-type accumulator →Forming machine →Water cooling tank →Sizing machine →Cold saw →Run-out table Our well-trained sales team is ready to assure the quality and effectiveness of your machine purchase. We will pay close attention to your orders and enquiries so as to fully assist you in choosing tube mill line with high performance and low cost. In addition, we provide elaborate after-sales service, since we believe that after-sales service is of high importance in satisfying customers.

在线联系供应商

Other supplier products

| Maxtube 219 Welded Steel Pipe Making Machine | Description We are famous with our Maxtube 219 welded steel pipe making machine which is specially designed to produce Φ114-Φ219mm and &... | |

| Φ38.1-76.2mm stainless steel tube making machine | Description We are manufacturer and seller of tube making machine in China. Maxtube-bg60 tube making machine is designed to produce stainless ... | |

| Φ32-127mm metal tube making machine | Description Tube making machine is the main equipment for the tube production line. As a specialized manufacturer, our diameter Φ32-127mm pi... | |

| Φ8-25.4mm stainless steel welded pipe mill | Description We are renowned for our diameterΦ8-25.4mm stainless steel welded pipe mill which is specially designed to produce Φ8-Φ25... | |

| Maxtube 28 Pipe Production Line | Description we are famous for our production line for pipe manufacturing, and our Maxtube 28 pipe production line is specially designed to produ... |

Same products

| 1435mm 数显轨距尺 | 卖方: 武汉联科瑞际轨道设备有限公司 | 铁路数显轨距尺主要用于铁路线路轨距、超高、查照间隔、护背距离 的测量。可供工务维修、大修、工程测量及其他有关部门线路作业时使用。 该仪器测量速度快、使用方便,白天、夜间均可使用,是工务、工程部门... | |

| NE-1525 Featuring Automatic Reset Battery Hydraulic Pipe Plumbing Tool | 卖方: Zhejiang Huaqi Information Technology Co., LTD | ● The automatic reset battery hydraulic pipe crimping tool is an industry- solution designed for ... | |

| DC series high efficiency european jaw crusher | 卖方: Shanghai Dongmeng Road and Bridge Machinery Co., Ltd. | Jaw crusher is widely used in ore crushing, construction aggregate production, construction waste... | |

| Internal Combustion rail drilling machine for rail construction | 卖方: 834406 | NZG-31型汽油机轨道钻孔机 该机器是铁路维护、施工和紧急维修作业中不可或缺的工具。采用空心钻头,具有快开功能的螺母夹紧机构,夹紧速度快,定位准确,钻孔快,操作简单,使用... | |

| Brown Fused Alumina For Abrasive | 卖方: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | Cooled and smelted under an electric arc at a high temperature above 2000 degrees, brown fused al... |