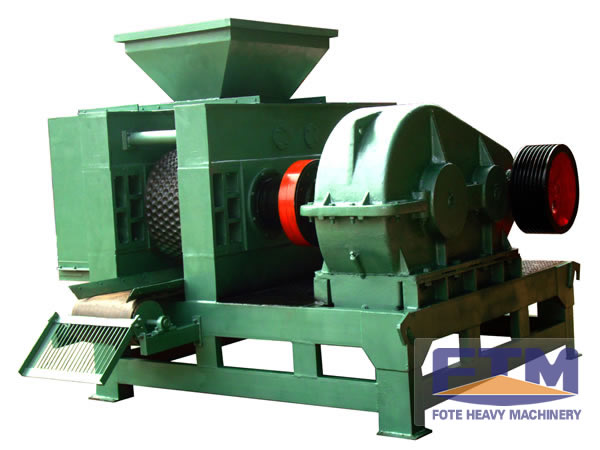

Wood Briquette Machine for Sale/Wood Pellet Machine Price

In furniture factories or other woodworking plants, there are plenty of waste wood produced every day. If not made use of, the waste wood pieces, chips or sawdust will remain worthless. But as a matter of fact, these waste woods are great fuel sources. One of the best ways to take their advantages is to make them into briquettes by briquette press machine.

The woo briquette machine for sale/wood pellet machine price is used to press crushed wood powder into high density hexogen sticks with hole in center.

The forming principle of wood briquette machine for sale/wood pellet machine price: All biomass contains large proportion of lignin and cellulose. The lignin itself has no melting point but it has softening point. When temperature reaches 120-160℃, the hot-water-soluble substance in lignin will melt, while at 180℃, lignin will soften and reshape. Under such condition, if some pressure is exerted onto the biomass, the lignin and cellulose inside will adhere each other and bond tightly. This is how biomass briquette is extruded by heating.

The forming conditions of wood briquette machine for sale/wood pellet machine price: Although we can utilize such biomass forming principle, it is realized under certain conditions. Since different biomass raw materials have different moisture content, volume and relative density, the requirement of forming conditions are not the same and their processing technologies vary.

1. Raw material moisture content: it greatly influences the briquetting process and briquettes quality. If moisture content is too high, the heating procedure will generate too much vapor which cannot smoothly be excluded through the middle hole of briquettes. As a result, the briquettes surface will crack, sometimes briquettes cannot form. But if the moisture content is too low, briquettes also won’t form, since certain amount of moisture will promote lignin soften. So the best moisture content for briquetting is 6-12%.

2. Forming temperature: it affects the briquette making speed, density, appearance and quality. Therefore, the temperature must be adjusted to meet the raw material, so as to guarantee the quantity and quality of briquettes. If the temperature is too low, it cannot soften the lignin, as a result cause blockage to the extruding drum; if too high, the biomass will severely decompose, which will cause briquette surface carbonization or even can’t form briquettes.

From what we talked above, we can come to a conclusion that to use the briquette press machine correctly, both the raw material moisture content and forming temperature should be controlled properly. As long as you operate it according to the Instructions, you will find it so easy to use briquette press machine.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

在线联系供应商

Other supplier products

| Carbide Ball Mill/Ball Mill Filling Rate | Ball mill is the key equipment for regrinding the materials after they are coarsely crushed.It is widely used in the field of the dry or wet grindi... | |

| High Capacity Barite Jaw Crusher Price/250mm X 500mm Jaw Crusher | The jaw crusher is mainly used for crushing the stones of which largest compression resistance is 320MPa. This series is complete in specifications... | |

| New Type Charcoal Briquette Making Machine for Sale | With the rapid development of the economy, the world's demand for charcoal has risen over the years. The annual demand in chemical and metallurgica... | |

| Professional New Ring Die Wood Pellet Mill Supplier | Basic Information of Professional New Ring Die Wood Pellet Mill Supplier It is a kind of bevel-gear wood pellet machine and a new-type product of d... | |

| High Quality Lime Powder Briquette Maker Price | The high quality lime powder briquette maker, also known as high pressure briquetting press, belongs to the dry powder briquetting machine series. ... |

Same products

| Wood engraving cnc machine for sale | 卖方: Shandong EAAK Machinery Co., Ltd | Feature ofwood cutting machine:The mechanical and electrical components of this model are interna... | |

| 大产量木片机 | 卖方: 山东宇冠机械有限公司 | 木材削片机用于切碎木材原木,废木材,废纸箱成木屑。 大产量。 只需告诉我们您的要求和材料最大直径。 | |

| Portable 1.1KW 1.5KW Woodworking Industrial Dust Extractors Machinery for Woodworkers Dust Collection | 卖方: SUZHOU RICO MACHINERY CO., LTD | From: | |

| 3D Wavy Board Carving Machine MDF Wall Panels Cutting Machine W1325VC | 卖方: SUZHOU RICO MACHINERY CO., LTD | From: | |

| MDF Board Cutting CNC Router Machine with Vacuum Table W1325V | 卖方: SUZHOU RICO MACHINERY CO., LTD | From: |