SWIR Cameras and Accessories in Machine Vision

Industrial Machine Vision cameras are the hearts of any vision system, no vision system is complete without it. For the last 10 years, Machine Vision industries have been reinventing itself to cope with the ever-increasing demands of manufacturing processes. From higher quality, higher speed, increasing complexities to cost-effectiveness.

HOW SWIR CAMERAS WORK IN MACHINE VISION?

At that glass inspection stage, rejects are identified, then shunted aside and reprocessed efficiently, greatly reducing scrap.

SWIR camera can detect the imaging quality of laser spots in industry, like detect the centroid energy of the spot.

Whether the laser spot meets the gaussian distribution and other purposes allowing operators to inspect both the interior and exterior walls of the bottle, as well as monitor the temperature uniformity and cooling rate of the material.

Objects may be the same color in the visible, but outside the visible wavelength band, their reflective properties can be very different. This enables SWIR cameras to detect the contaminants and allow systems to remove them from the processing line.

SWIR CAMERAS IMAGE

Beam tracking

Hot glasses imaging

Human Identification

Industrial Inspection

Agricultural Inspection

WHAT IS A MACHINE VISION CAMERA?

Machine vision is the use of a camera or multiple cameras (mostly SWIR cameras) to inspect and analyze objects automatically, commomly used in an industrial or production environment. The data acquired by the industrial machine vision cameras can be used to control a process or manufacturing activity.

A lot of manufacturers and factories use automated machine vision camera systems instead of human inspectors to do the work because the camera system is better suited to mechanical inspection tasks. Machine camera vision systems works continuously. It can inspect hundreds or even thousands of parts per minute, and provides more consistent and reliable inspection results than human inspectors, thus manufacturers can save money and increase profitability. high resolution machine vision cameraand high speed machine vision camerais their best choice.

Applications of machine vision system for automatic inspectionInclude:

Quality assurance

Robot/machine guidance

Test and calibration

Real-time process control

Data collection

Machine monitoring

Sorting/counting.

WHY CHOOSE SWIR CAMERAS AS MACHINE VISION CAMERAS?

Machine Vision cameras require cameras that can see the smallest defects, operate at fast frame rates, and image with wide field-of-view. Industrial inspection camera imaging also requires cameras with the lowest cost per megapixel.

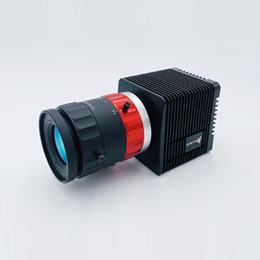

SWIR cameras features indium gallium arsenideInGaAs sensors in a compact format suitable for machine vision.

SWIR camera delivers responsivity and low noise, and enables machine vision camera systems designers to inspect beyond the visible light range.

GHOPTOis athe most professional machine vision camera manufacturers and machine vision system companies, we provide high quality machine vision cameras for clients. Feel free to contact us and get machine vision system price!

GHOPTO is aprofessional image sensor companies, we provide machine vision surface inspection, machine vision system in robotics ppt, SWIR Sensors, SWIR Cameras, SWIR Lenses & Accessories and etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| 640 SWIR InGaAs High Cost-Performance Camera USB3.0 | This camera using SWIR technologyindependently developed and designed by GHOPTOhas a resolution of 640×512, 15μm pixel pitch, and is equi... | |

| GH-SW640Pro-U3 SWIR Camera | GH-SW640Pro-U3 SWIR Camera The SWIR Cameraseries feature a 640 x 512 pixel InGaAs focal plane array (FPA) with a pitch of 15μm. The camera oper... | |

| GH-SW320-U2 & GH-SW320-Gnet SWIR Camera | The SWIR Camera series feature a 640 x 512 pixel InGaAs focal plane array (FPA) with a pitch of 15μm. The camera operates in the 900nm – 1... | |

| 640 SWIR InGaAs High Cost-Performance Camera USB2.0 | The 640 series is based on an InGaAs detector with a 640 x 512 pixel resolution. Our USB vision cameracamera is offered with a full-frame rate of... | |

| SHORT WAVE INFRARED IR CAMERAS | Specialist in Indium Gallium Arsenide (InGaAs) imaging technology, GHOPTOmanufactured a wide range of high-quality short wave infrared (SWIR) camer... |

Same products

| HBVCAM Sony IMX317 8M Pixle HD 4K CMOS Camera Module | 卖方: Huiber Vision Technology Co., Ltd | The HBVCAM Sony IMX317 8M Pixel4k Usb Camera Moduleis a cutting-edge imaging solution designed to... | |

| FOV 100 degree distortionless lens OV2710 HD CMOS camera module | 卖方: Huiber Vision Technology Co., Ltd | HD CMOS camera module from- the ultimate solution for high-quality imaging and video capture! Thi... | |

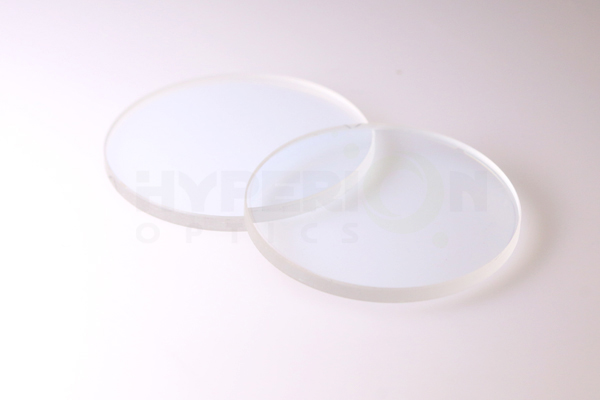

| Sapphire Lenses | 卖方: Hyperion Optics | Sapphire is the best medium for sapphire glasslenses that require a broad spectrum of light trans... | |

| Magnesium Fluoride Lenses | 卖方: Hyperion Optics | Uses of Magnesium Fluoride CVD magnesium fluoride (MgF2-CVD) has good mechanical properties, che... | |

| Germanium Lenses | 卖方: Hyperion Optics | In the range of 2-12 μm, germanium is the most commonly used material for the production of sp... |