PCB Prototype

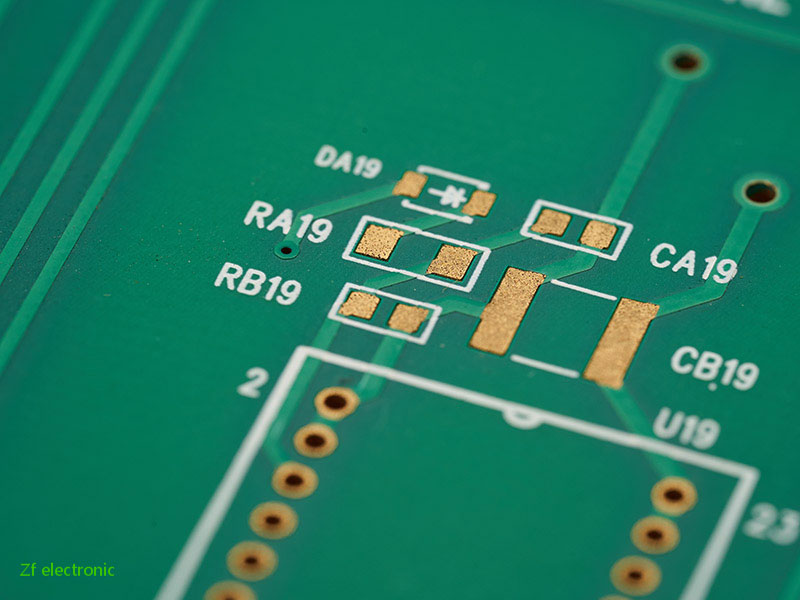

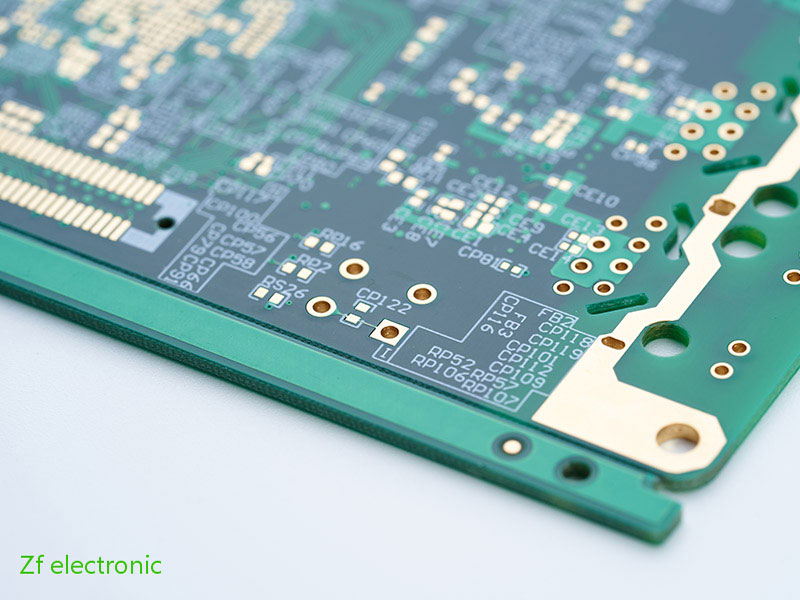

ZF Electronics, as one of the top pcb assembly supplierin China, can provide customers with single-sided PCB, double-sided FR4 PCB, metal core PCB, heavy copper PCB, rigid PCB and rigid-flex PCB. It provide pcb board, single layer pcb, multi layer board, rigid flex pcb, aluminum pcb,etc.

Are you creating a new printed circuit board design? Printed circuit boards have many technical uses. However, it is more cost-effective to conduct a concept test before entering the PCB manufacturing stage. The PCB prototype allows the idea to be approved in a cheaper way before the full printed version is manufactured. Even if you may feel that you know exactly how to design a PCB, you must first have a prototype board PCB.

The two primary stages in developing products such as electronic circuit boards are simulation and prototyping. Although sometimes overlooked, it is done through software, and its purpose is to verify whether the circuit design meets its performance and functional design criteria. An electronic circuit simulation is a valuable tool as it reduces the need to build unnecessary boards that have little chance of meeting design goals. Passing the simulation test is only the first step in electronic design, as the hardware device or PCB must also be tested. Such tests, called PCB prototypes, can be defined by their purpose, process, and result.

The purpose of PCB prototype is to build and test its functionality, operation, and physical implementation of the design, as well as its structural integrity. Structural integrity refers to the quality and reliability of the PCB, which is usually regulated according to its intended use.

PCB prototyping is usually divided into three stages. In the same way that several simulations are required before final parameters are determined and requirements are met, prototyping is cyclical and usually requires several iterations before the final PCB construction is completed.

For each PCB prototype iteration, an assembled PCB is created and tested, and the test results determine whether additional iterations are required. Usually, further iterations mean redesigns or design changes and the need to build and test new boards. The result of the PCB prototype is a design that can be used for the PCB, depending on the intended application of the board.

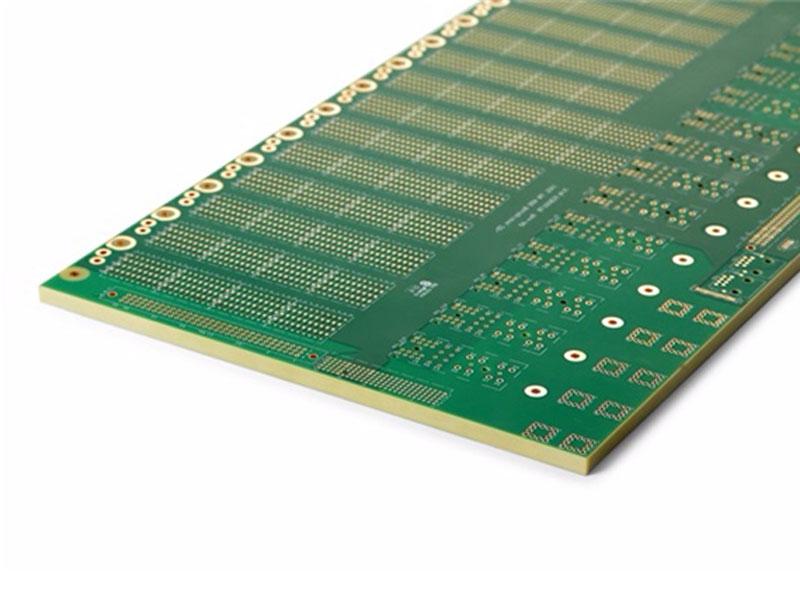

As mentioned above, PCB prototyping is usually an iterative process requiring multiple design changes and rebuilding before the final design is completed. In practice, design quality is proportional to the number of iterations, as each iteration produces a better quality design. Although these cycles can be anticipated, it is usually desirable to keep their number to a minimum. The larger the number of iterations, the more time and cost it takes to develop. However, in most cases, time and cost are limited. For example, most developers have a delivery schedule, which may vary depending on the clients.

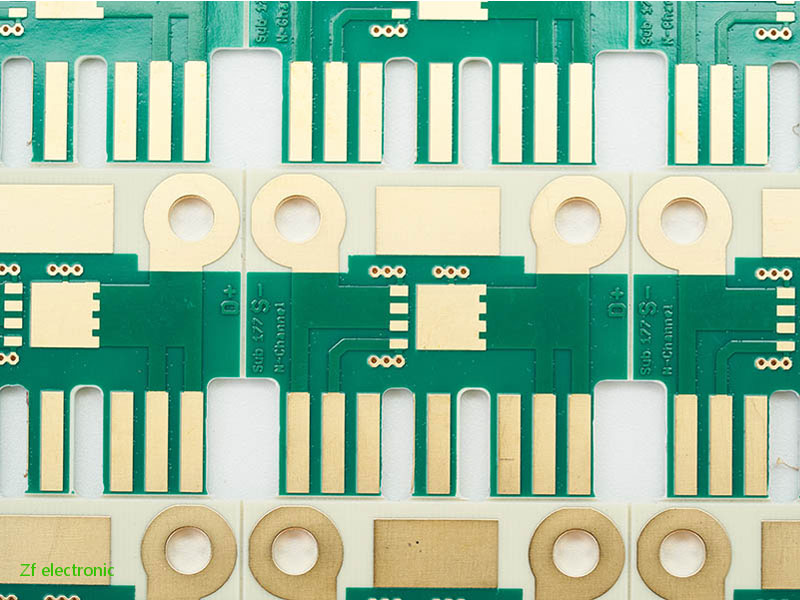

Not surprisingly, there are various strategies to reduce lead times, one of which is the use of parallel prototyping strategies. Parallel prototyping can be defined as physically testing different board implementations collectively rather than sequentially, as is done for typical prototypes. Parallelization allows all aspects of the design to be tested or analyzed with a view to improving the overall design more quickly than sequential iterations would allow. There are many measures to improve the effectiveness of parallel prototyping when it is implemented, which includes using cheaper components, larger boards, or otherwise relaxing board parameters.

These methods may be effective and can be applied in typical prototyping; however, each will need to be determined individually and sequentially to provide an accurate comparison, which will, in effect, extend the prototyping process. However, if these alternative designs are manufactured and tested in a simultaneous or parallel manner, they can make the prototyping process more efficient. In these cases, parallel PCB prototyping offers clear advantages.

Parallel prototyping allows the development of a single design or multiple competing designs that meet the design objectives. In fact, because board manufacturing must be stopped until testing and redesign is completed, the typical process can only be as fast as parallel processing. For parallel prototypes, alternative designs can be manufactured during this downtime, which will significantly increase efficiency.

Clearly, learning from software development and establishing a parallel prototyping strategy can be very beneficial in improving PCB development, but to take full advantage of this approach, manufacturers should have an agile manufacturing process and be able to respond quickly to changes in board design.

Do you need a PCB prototype? We offer our customers high-quality PCB prototypes and the best service. Please do not hesitate to ask for information if you need it. And if you have questions about our PCB production capacity, or the specifications required for your custom project are not listed on this page, please feel free to contact us. We will reply within one workday. We will continue to provide quotation support and design support. Welcome to learn about our production process.

Those prototype pcb board manufacturerprovide prototype circuit board fabrication. And if you want buy pcb prototype, you can contact us. And the pcb prototype priceis very reasonable,because of the pcb prototype low cost.

在线联系供应商

Other supplier products

| Multilayer PCB | Printed circuit board (PCB) now plays the most important role in electronic products. The PCB used in the past was very simple and limited to a sin... | |

| Rogers PCB | With the development of electronics, the production of electronic products also requires more and more materials, such as high-frequency materials.... | |

| Thick Copper PCB | ZF Electronics, as one of the top pcb assembly supplierin China, can provide customers with single-sided PCB, double-sided FR4 PCB, metal core PCB,... | |

| Halogen-Free PCB | ZF Electronics is a China Shenzhen-based printed circuit board assembly manufacturerand PCB assembler. Shenzhen has been the world's center of elec... | |

| Thick Copper PCB | PCBs are usually bonded to a layer of copper foil on a glass epoxy substrate, the thickness of which is usually 18μm, 35μm, 55μm and 70&mu... |

Same products

| 断路器开关 | 卖方: 839459 | 断路器开关产品: 断路器开关,作为电路保护的核心元件,集安全、高效、智能于一身。它能自动检测并切断异常电流,有效防止电气火灾和设备损坏,为家庭、工业及商业用电提供坚实的安全屏障。采用先进技术与材... | |

| VZO-12系列户外高压真空断路器 | 卖方: 839459 | 户外高压真空断路器: VZO-12系列型户外高压真空断路器(以下简称断路器)为额定电压12kV,三相交流50Hz的户外配电设备。它采用真空灭弧和SF6气体作为绝缘介质,是MVXOZ-12型柱上真... | |

| 真空断路器 | 卖方: 839459 | 固封式户内高压真空断路器: VZCN-12系列户内高压真空断路器,额定电压为12KV,三相交流50Hz的户内高压开关设备,适用于发电厂、变电所及工矿企业输配电系统的控制或保护开关,尤其适用于高海... | |

| 真空断路器 | 卖方: 839459 | 侧装式户内高压真空断路器: 真空断路器通常可分多个电压等级,低压型一般用于防爆电气使用,例如煤矿等等。其额定电流达到5000A,开断电流达到50kA的较好水平,并已发展到电压达35kV等级。 ... | |

| DELIVER MOLDING MECHANICAL DESIGNS SYSTEMATICALLY | 卖方: GreensTone (Shenzhen) Electronics Co., Limited | GreensTone mechanical design engineers will work with your team to design and test the best solut... |