GLPOLY thermal gap pad is applied in military equipment

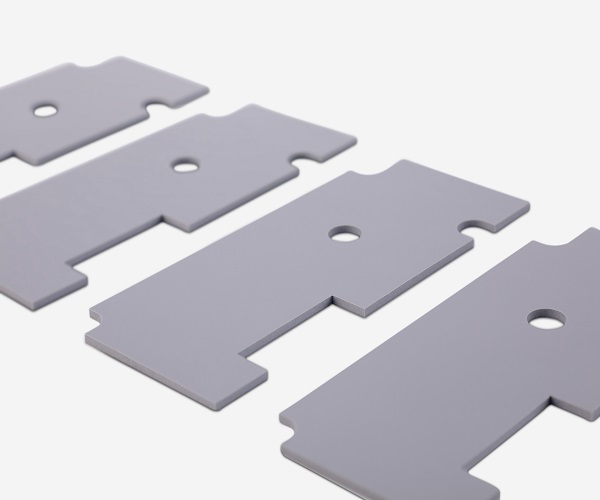

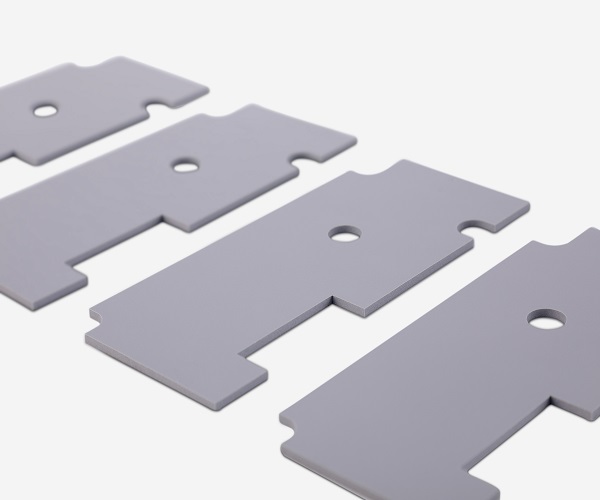

Why can GLPOLY stand out from competition and be applied in military equipment of 2019 National Day Parade? We are not boasting and flaut ourself, actually we had received certificate of merit from department concerned. The market is deluged with thermal gap pads, common customers can not distinguish high performance thermal pad from bad ones, because they don’t have a special equipment to test and verify what the manufacturers marked. Many peers said that they can produce thermal gap pad with 15.0W/mK or 17.0W/mK of thermal conductivity, most of them falsified. We do not want to belittle peers, but after we tested their product, we got fake information often. one is falsification thermal conductivity, the other one is hgih thermal resistance. Bad performance causes distrust of customer in domestics brand. GLPOLY sticks to principle of integrity, we show customer what it is. The raw materials are imported from Germany and Japan, in order to enhance thermal performance, secondary processing will be proceeded by nanoscale grinder. It will reduce the particle size and increase specific surface area to decrease thermal resistance and improve thermal performance. No one else proceeds like this. Customer requested 5.0W/mK of thermal conductivity at least, when we learned application, we recommended thermal gap pads with 5.0W/mK and 6.0W/mK. Customer satisfied with parameters, but they prefered to test by themselves.

Other supplier products

|

|

Thermal Sealing Compound |

GLPOLY Two-part thermal gap filler 1:1 mixed, no by-product, ultra conformable, fast cure by heating. It is designed for automated dispensing syste... |

|

|

GLPOLY thermal gap filler will be applied in volume production by the major auto companies |

GLPOLY Thermal gap filler has been applying in military equipment shown in parade, it’s no doubt that GLPOLY thermal gap filler will be appli... |

|

|

Thermal Grease |

Thermal Grease provides high performance, low thermal impedance and low bondline thickness. As afirst-class thermal interface materials supplier, h... |

|

|

GLPOLY thermal gap pad--high performance, true parameter |

GLPOLY thermal gap pad has been applied in equipment showd on National Day Parade and EV in four major auto enterprises represented by NIO. For tha... |

|

|

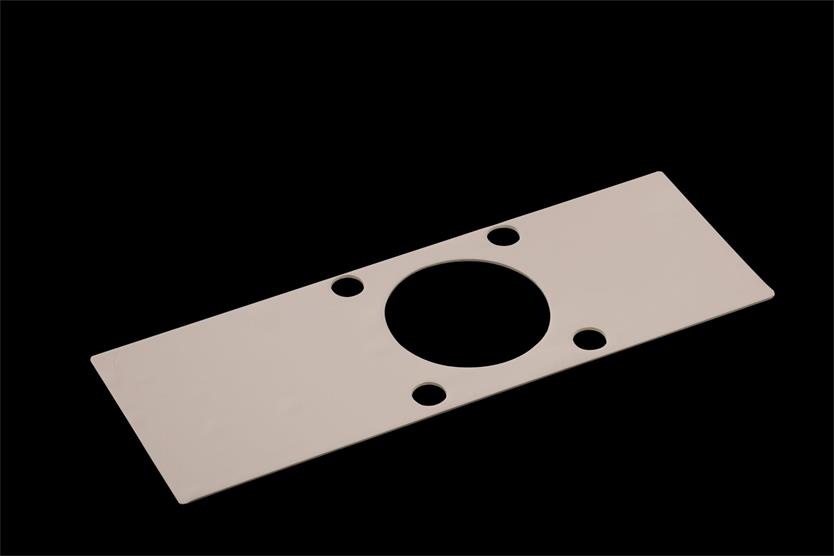

Low Density Thermal Pad for Vehicle |

Thermal pad for EV, Low density, ultra conformable, low stress, designed for new energy vehicle, fiberglass reinforced for punching and tear resist... |

供应产品

Same products

|

|

power steering fluid filter HC9404FCT13H oil-return filter |

卖方: Dongfang Yoyik Engineering Co., Ltd |

Facing the changes in the energy industry, YOYIK keeps pace with the times, not only focusing on ... |

|

|

lube oil filter FRD.V5NE.07F dehydration filter |

卖方: Dongfang Yoyik Engineering Co., Ltd |

As a leading domestic supplier of power station equipment accessories, YOYIK is well aware of the... |

|

|

filter element cartridge DP301EEA10V/-W governor inlet filter |

卖方: Dongfang Yoyik Engineering Co., Ltd |

Since its establishment in 2004, YOYIK has become an indispensable partner in heavy industries su... |

|

|

filter element cartridge DP301EEA10V/-W governor inlet filter |

卖方: Dongfang Yoyik Engineering Co., Ltd |

Since its establishment in 2004, YOYIK has become an indispensable partner in heavy industries su... |

|

|

AIT500-SG High-Precision Current Sensor Transducer |

卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd |

AIT500-SG 凭借其在现有直流传感器技术基础上应用的多点零磁通技术系统和高频纹波传感通道,在全带宽范围内实现了高增益和高测量精度。

多点零磁通技术系统通过结合激励磁通闭环控制、自激励磁通... |