ABS Plastic Injection Mold 49443

Brief Introduction of Hanking ABS molds

Mould Name: Plastic Injection ABS Molds

Part Material: ABS

Product Size: 172*123 mm

Product Description: clear window

Mould Cavity: 1 Cavity

Mould Size: 300*380*250 mm

Mould Cavity Steel: ASSAB 8407

Mould Injection System: hot runner

Mould Ejection System: Round ejector

Mould Cycle Time: 38s

Mould Life Cycle: 500,000

Lead Time: 42 working days

Mold export to: Europe

For ABS plastic part molds, HanKing will make good plastic injection mold design from wall thickness, draft angle, venting, ejector system, balance and a good runner.

Do you know how to mold abs plastic?

Design for ABS Plastic Injection Molds

The wall thickness of the product is related to the flow length of the melt, production efficiency, and use requirements. The ratio of the maximum flow length of the ABS melt to the wall thickness of the product is about 190:1. This value will vary depending on the grade. Therefore, the wall thickness of the ABS product should not be too thin. For products has electroplating requirement, the wall thickness should be slightly thicker to increase the adhesion of the coating to the surface of the article. For this purpose, the wall thickness of the product is preferably between 1.5 and 4.5 mm.

When considering the wall thickness of the product, we should pay attention to the uniformity of the wall thickness, do not make big difference wall thickness. For the products to be electroplated, the surface should be flat without unevenness, because these parts are difficult to remove due to static electricity, which is difficult to remove. The fastness of the coating deteriorates. In addition, the presence of sharp corners should be avoided to prevent stress concentration. Therefore, it is advisable to use arcs for transitions such as corners and thick joints.

The draft angle of the product is directly related to the shrinkage rate. Due to the different grades, the different shapes of the product and the different molding conditions, the molding shrinkage rate has a certain difference, generally 0.3~0.6%, sometimes It is 0.4~0.8%, so its product molding size accuracy is high. For the ABS product, the draft angle is considered as follows: the core portion is 31° in the demolding direction, and the cavity portion is taken 4 (/1° 20' in the stripping direction. For products with complex shapes or letters and patterns, the draft angle should be appropriately increased.

Since the products surface finish has a great influence on the electroplating performance, any slight scratch on the surface will be apparently exposed after electroplating, so that no damage is allowed on the cavity. It is also required a large effective area for ejection, good synchronization of the multiple ejector pins in the abs injection molding processand uniform ejection force.

In order to prevent the occurrence of poor venting in the process of filling, cause melt burning, the obvious seam line and other problems, it is required to open a vent hole or venting groove in which the depth is not more than 0.04mm, so the gas can be exhausted.

Following the concept of customer first, HanKing Mould dedicates to be a trustworthy tooling company by designing and manufacturing plastic injection molds, providing custom plastic molding manufacturing and services according to every individual's requirements. HanKing Mould Enginering Ltd.successes are ensured by our management capability, technical knowledge, advanced plastic tooling equipment and professional injection molding services. We are pursuing better quality and technical capability to meet the demands of increasing mold making markets.

We are a responsible injection moulding companies chinaand mold maker company and have experience in supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. You can fully trust our production sites, products and place your orders.

在线联系供应商

Other supplier products

| Double Injection Mold Parts | Double Injection Mold Parts Part function: Plastic Lid for coffee machine Part Standard according to ISO 11496 Surface: SPI A-2 finish Flammabil... | |

| Industrial Molding Parts | Industrial hanking mould parts are referred to the plastic parts of industrial products, HanKing Mould Enginering Ltd.preferred to think of it as n... | |

| Over-Molding Parts | The plastic injection overmoldingpart is a process that can bond different materials by the injection molding. Over-molding in HanKing is a techno... | |

| Plastic Parts Gallery | It is a complex task to design plastic parts involving many factors according to varoius requirements for different industires. "How is the part to... | |

| Plastic Precision Car Parts | Mould Type: Plastic Precision Car PartsMould Production Material: PC, PP, PA6, PA66, PE, ABS, HDPE, TPE, TPU, PET, PPS, POM, PBT, PMMA, PPS, SAN... |

Same products

| AIT500-SG High-Precision Current Sensor Transducer | 卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd | AIT500-SG 凭借其在现有直流传感器技术基础上应用的多点零磁通技术系统和高频纹波传感通道,在全带宽范围内实现了高增益和高测量精度。 多点零磁通技术系统通过结合激励磁通闭环控制、自激励磁通... | |

| JWA2-M Oil Micro Moisture Sensor | 卖方: Shenzhen Joinwe Smart Co.,Ltd | JWA2-M micro moisture sensorcan quickly and accurately detect oil water activity (moisture satura... | |

| Made in China Displacement sensor 4000TDG for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Displacement sensor 4000TDG for thermal power plant YOYIK professional production ... | |

| China made Control System LVDT 5000TDGN for power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made Control System LVDT 5000TDGN for power plant Dongfang Yoyik has advanced technology a... | |

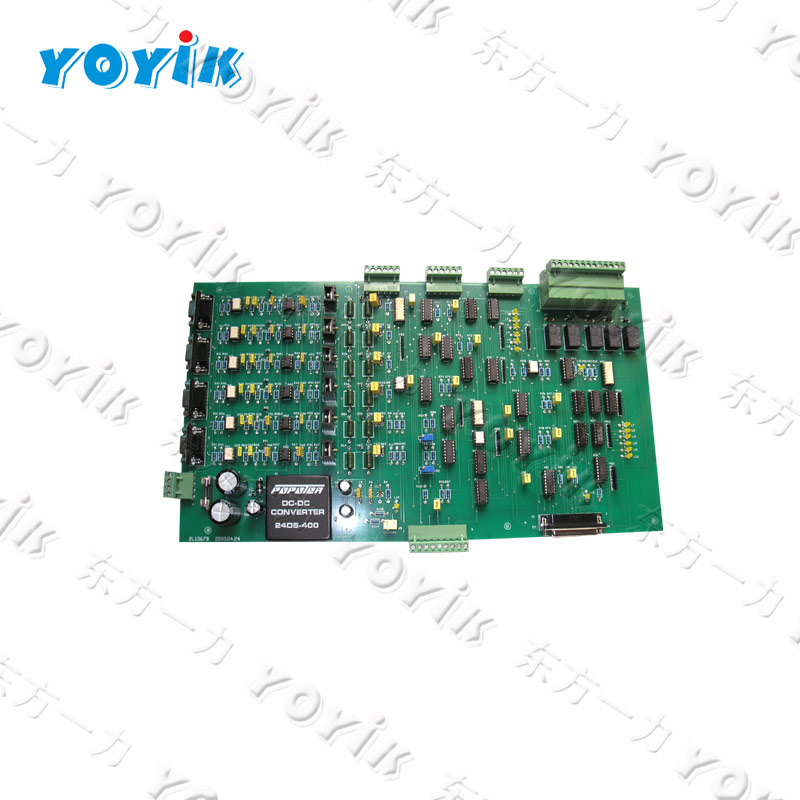

| China supplier main control board APF7.820.117A-A power plant spare parts | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China supplier main control board APF7.820.117A-A power plant spare parts Dongfang Yoyik is spec... |