Automotive Mold

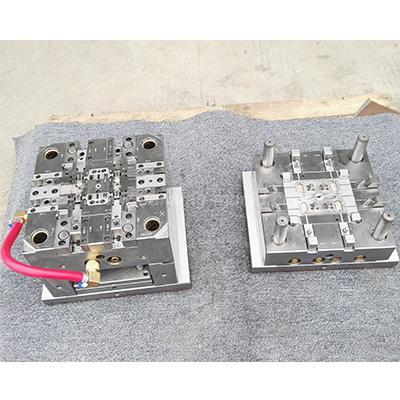

Professional Automotive Injection Mold for Cartridge Fuses

TolerancesPlates and Mold Base Components:± 0.013 mm (± 0.0005 in)Cavity components: ± 0.005 mm (± 0.0002 in)CAD/CAM SoftwareAutoCAD 2007UG NX8.5 CADUG NX8.5 CAMPro-E Wildfire Version...

More

Vehicle Switch Mold Tooling

Vehicle Switch Mold Tooling

Mould Name: Switch Mould for carPart Material: Dupont Zytel Product Size: Product Description: Switch PieceMould Cavity: 8 Cavities Automotive SwitchMould Size: Suitable Injection Machine:Mould Cavity Steel...

More

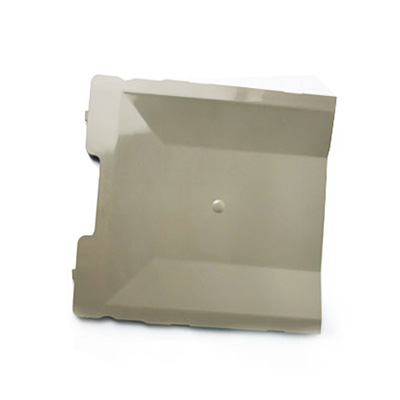

OEM Plastic Housing Auto Parts Mould

OEM Plastic Housing Auto Parts Mould

Specialize in providing plastic injection moulds & molding service to global clients.We provide OEM Plastic Housing Auto Parts Mould to the customers from Germany, USA, Mexico, Italy, Israel...

More

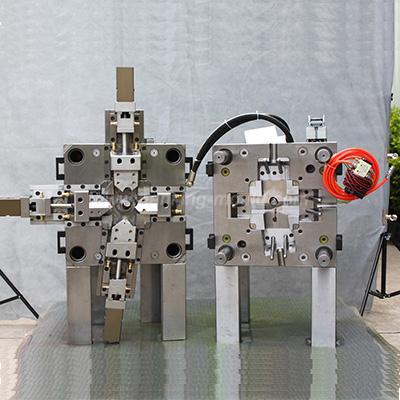

Plastic Auto Parts Sensor Mould

Plastic Auto Parts Sensor Mould

HanKing Mould produce all different kind fuse and connector for international OEM company, we have a lot of experience to short the project development time.

More

Precision Automotive Parts

Precision Automotive Parts

Mould Name: Precision automotive plastic mouldPart Material: PA66 G30Product Size: Product Description: BODY plastic Mould Cavity: 4 Cavities MoldMould Size: Suitable Injection Machine:Mould Cavity Steel...

More

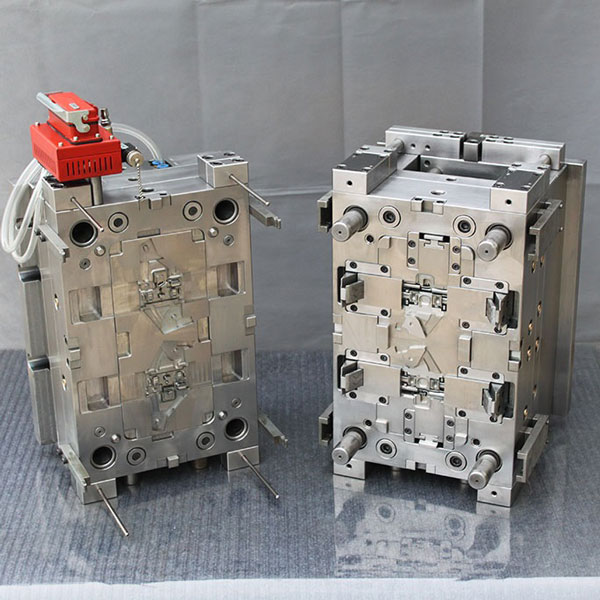

Hot Cold Runner Automotive Injection Mold for Led Protector

Hot Cold Runner Automotive Injection Mold for Led Protector

Mould Making Capabilities:Multi-CavityValve GateHorizontal Valve GateHot Runner3-Plate ToolsStripper Plate2K MouldsCold RunnerFully Automated De-moldingGas Assisted EjectionInsert...

More

Electrode of Auto Plastic Component Mould

Electrode of Auto Plastic Component Mould

HanKing Mould produce all different kind fuse, connectors and electordes for international OEM company, we have a lot of experience to short the project development time.Mould Name: Electrode of Auto...

More

High Precision Auto Injection Mould for Fuse

High Precision Auto Injection Mould for Fuse

HanKing Mould produce all different kind fuse and connector protector for international OEM company, we have a lot of experience to short the project development time.

More

Car Parts Mold

Car Parts Mold

Plastic Injection Mould in HanKing Advantages:1. Professional mould designers; 2. Rich mold making experience, well know standard from different country; 3. Stable and high quality but reasonable price; 4. On time delivery, fast mold development schedule.

More

Custom Plastic Auto Parts Mould

Custom Plastic Auto Parts Mould

Specialize in manufacturing various plastic injection moulds & moldingWe provide Custom Plastic Auto Parts Mould to the clients from Germany, USA, Mexico, Italy, Israel, Romania, Switzerland...

More

Customized Terminal Mould for Auto Plastic Parts

Customized Terminal Mould for Auto Plastic Parts

Developing Flow Chart for Customized Terminal Mould Purchase Order (PO3. Mould Design Design for Manufacturability (DFM) Pre-DesignMoldflow 3D Mould Design Design Approval by Customer....

More

Automotive Diode Plastic Car Component 8 Cavities Injection Mould

Automotive Diode Plastic Car Component 8 Cavities Injection Mould

As a plastic molds maker, HanKing Mould advantage for Plastic Car Component Injection Mould Professional tooling design team with more than 10 years experience.Wide choice for mould steel such as...

More

Expansion Tank Cover Mould

Expansion Tank Cover Mould

Mould Name: Expansion Tank Cover MouldPart Material: PA66Product Size: Product Description: TANK EXPANSION COVER LHMould Cavity: 2 CavitiesMould Size: Suitable Injection Machine:Mould Cavity Steel...

More

Automotive Expansion Tank Mould

Automotive Expansion Tank Mould

Mould Name: Automotive Expansion Tank MouldPart Material: PA66Product Size: Product Description: TANK EXPANSION INTERNAL RHMould Cavity: 2 CavitiesMould Size: Suitable Injection Machine:Mould Cavity Steel...

More

HanKing Mould serves global Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide customers the fast development time and stable quality to ensure the new project running well. HanKing engineer will analysis the filling to obtain the best gate position the best flowing regime, and design the best cooling channel to ensure the minimum wrapping deformation and we have a very good injection operator to help set the best injection parameter to avoid any development time waste and improving the molding parameter reliability.

HanKing Mould is very experienced in small and medium-sized precision automotive molds, in the past years, the types of products we involved were included fuse and fuse box, connector, switch, relay, sensors, actuators, terminal, valve, handle and other body accessories. We are one of the leading automotive mold makers in China.

Why are Automotive Moulds Important?

In the development of the automotive industry, the proportion of plastic parts in automotive parts is very large, and the demand for plastic parts is increasing day by day because plastics have the advantages of beautiful appearance, lightweight and easy processing. Most plastics have a specific gravity of 0.9 to 1.6, and the proportion of glass fiber reinforced composites will not exceed 2.0, while A3 steel is 7.6, brass is 8.4, and aluminum is 2.7. The use of plastic can reduce the weight of parts by about 40%, and the cost can be greatly reduced, which makes plastic the preferred material for automotive light-weighting. Plastic is easy to molding parts with complex shapes. According to the plastic composition of the plastic, by adding different fillers, plasticizers and hardeners to produce the desired properties of the plastic, changing the mechanical strength and processing properties of the material to meet the requirements of different parts of the car. The plastic consumption of each auto part accounts for 20% of the total vehicle materials and may reach 35% in the future. When the auto company develops a new car, it needs to use hundreds of sets of automotive plastic injection molds, which requires the quality assurance of plastic parts in production, and the quality of plastic parts is determined by the mold.

Which Parts of the Car Are Commonly Used in Plastic?

As the automotive mold makerand automotive moulding company. Bumper, the instrument panel accessories, inlet grille, fender, radiator grille, trim panel, engine parts, Water tank accessories, air conditioning accessories, air filter accessories, various kettles, seat accessories, floor panel accessories, roof panel accessories, bar accessories, steering wheel accessories, door trims, rearview mirrors and various fastener, front and rear lamp, etc.

Following the concept of customer first, HanKing Mould dedicates to be a trustworthy tooling company by designing and manufacturing plastic injection molds, providing custom plastic moldingmanufacturing and services according to every individual's requirements. Hanking's successes are ensured by our management capability, technical knowledge, advanced plastic tooling equipment and professional injection molding services. We are pursuing better quality and technical capability to meet the demands of increasing mold making markets.

We are a responsible china plastic injection mold makerand mold maker company and have experience in supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. You can fully trust our production sites, products and place your orders.

在线联系供应商

Other supplier products

| Insert Molding | What is insert molding? Insert molding refers to a molding process in which an integrated product is made by inserting a pre-prepared metal materi... | |

| Double Injection Mold Parts | HanKing MouldEnginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold ... | |

| Insert Molding | What is insert molding? Insert molding refers to a molding process in which an integrated product is made by inserting a pre-prepared metal mater... | |

| Home Appliance Mould | HanKing Mould Enginering Ltd.offer various products to meet people’s needs, including home appliance mold. Embroidery Machine Frame Mould Pl... | |

| Automotive Mold | HanKing Mould serves global Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide cust... |

Same products

| AIT500-SG High-Precision Current Sensor Transducer | 卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd | AIT500-SG 凭借其在现有直流传感器技术基础上应用的多点零磁通技术系统和高频纹波传感通道,在全带宽范围内实现了高增益和高测量精度。 多点零磁通技术系统通过结合激励磁通闭环控制、自激励磁通... | |

| JWA2-M Oil Micro Moisture Sensor | 卖方: Shenzhen Joinwe Smart Co.,Ltd | JWA2-M micro moisture sensorcan quickly and accurately detect oil water activity (moisture satura... | |

| Made in China Displacement sensor 4000TDG for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Displacement sensor 4000TDG for thermal power plant YOYIK professional production ... | |

| China made Control System LVDT 5000TDGN for power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made Control System LVDT 5000TDGN for power plant Dongfang Yoyik has advanced technology a... | |

| China supplier main control board APF7.820.117A-A power plant spare parts | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China supplier main control board APF7.820.117A-A power plant spare parts Dongfang Yoyik is spec... |