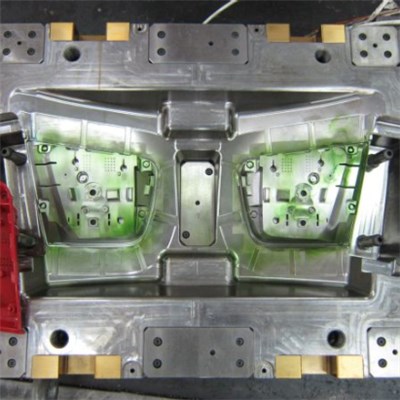

Plastic Injection Moulding

Product Details: Plastic Injection Molding ,Website:, Home Appliance Mold , Auto Parts Moulding , Plastic Injection Mould , Plastic InjectionItem Name:plastic molding parts & injection part1. MaterialABS, flame-resistant ABS,PC,PS,PP,PVC,TPR,TPU,TPE , HDPE,PMMA etc2. Mould CavitySingle or multi-cavities3. Mold baseLKM or Equivalent standard mould base4. Surface FinishlNAK 80 prehardened steel,718, 718H,H13 etc.5. Surface Finishchrome plating, silk-printing, Laser etching, texture, color painting etc.6. Injection Matching Size20 sets range from 120T To 850T7. Max Mould Size1700×1700mm8. Max Product Size1200×1200mm9.Surface TreatmentChrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.10.Mould Leadtime20-30 days depending on the size of the products12.Injection Maching Size:15-30 days depending on the quantity of the order12.Injection Maching Size20 sets range from 120T to 850T13. Mold Life50,000shots to 500,000shotsThe product in the pictures are our customers' OEM products, for reference only.Plastic Molded Parts 1.Professional manufacturer 2.High quality,best prices and quick delivery Plastic Injection Solution:1. Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class production2. Parts are widely used: Industrial, Automotive, Electronics & MedicalTechnical Skills - Development, Design Skills1. Design Consultation & Assistance2. Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysisMaterial Selection Assistance1. Quick turn-around prototype support2. Secondary Operations including machining, welding & assemblyMolding - High Precision, High Concern1. Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stamping2. 40 Molding machines from 80TONS to 1400TONS3. High precision molding from medical to fiber optics componentsSecondary Operations - Value Added Service1. Pad Printing2. Sonic Welding3. Assembly & PackagingOur Professinal injection mold service: 1. Automobile mold 2. Gear mold 3. Cap mold 4. Unsrewing mold 5. Overmold, overmolding, Two Shot Over-Molding, Two Color Over-Molding, Insert Over-Molding 6. Hot runner mold 7. Injection molding Company Advantage:1.Professional manufacturer 2. Advanced equipment and excellent R&D Team3. Highly skilled manufacturing process4. A variety of ODM&OEM product range5. Strict quality Control System6.Software for specification drawings: Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM7. Competitive priceTo Customers: Dear Friends, That is very honor that you find our website! In order to fast efficient reply your requirements, please send us your RFQ to Please also advice detail requirement like surface, quantities and tolerance. You can surely get reply within 24 hours! Best regards, Shenzhen Tasuns Industry Ltd.

Other supplier products

|

|

|

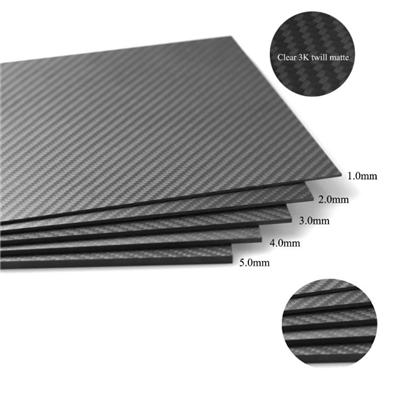

Situated in the convenient China, Tasuns Composite Technology Co.,Ltd is one of the competitive best price of carbon fiber sheets parts with cheap ... |

|

|

|

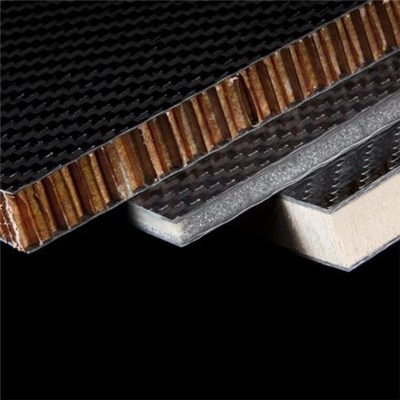

Product Details: Carbon fiber Honeycomb Panel is made of carbon fiber and different core like nomex, PVC, pp, glassfiber and so on, it has high fat... |

|

|

|

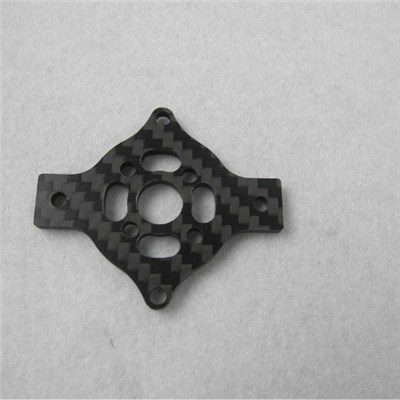

Product Details:Material AcceptableAluminum AL5052,Website:, AL6061, AL6063,AL7075 etc.Stainless steel SS201, SS303, SS304, SS316 etcBrass/CopperC... |

|

|

|

Basic InfoModel NO.: LFCR0224Certification: ISO9001Customized: CustomizedApplication: Metal Cutting Machine,Website:, Metal Processing Machinery Pa... |

|

|

|

Product Details: Place of Origin:ChinaSupply Type:Make-to-OrderRaw Material:Carbon Fiber Fabric&Epoxy ResinWeave:Twill/Plain/UDType:1K, 1.5K,3K,6K,... |

供应产品

Same products