Preform Mould

Mould name:Preform Mould Shaping Mode:Blow MouldPreform Mold,Website:, Preform Molding, Preform Moulding, Preform Molds, Preform MouldsHow preform mold is good?What is the impact of hot runner nozzles select it, I learned a little of the following: product quality, product design, plastic raw materials, molds, cycle time, gates, nozzles, runner, temperature controller, and an injection molding machine performance and so on. When we have a very accurate understanding of these, it is possible to choose the right for a hot runner nozzle. Choosing the right preform mold?1, product weight: different weight for hot runner product requirements are completely different.2, plastic raw materials: Different materials have different Plastic processing variables, those variables will affect the choice of processing hot runner system.3, mold: Cavity like how much? Distribution nozzle distance how? Processing what kind of material? Etc. These are related with the optional hot runner system mold elements.4. cycle: rapid production cycle means increased nozzle requirements. For example, the nozzle to accurately transfer the heat, but also durable.5, gate: For point-gate, in order to maintain a good balance of heat in each molding cycle, the sharp-tongued heat must have melted seal material and cooling functions. The valve gate is used mechanical methods to seal the gate.6, the nozzle: nozzle size can be general, temperature distribution, physical characteristics, the materials (copper, steel, etc.) as well as ease of maintenance and price make that distinction.7, the flow path: use the hot runner system avoids the generation of the material, thereby saving raw materials, while eliminating the need to manually in the past, robots or other means to remove the feeding process.8, the temperature control: Each nozzle must be connected to a relatively complex temperature controller9, performance injection molding machine: the ability to install a given size die, to provide sufficient clamping force, the cycle time required to operate, enough material plastics etc.10, product design: In general, we all know that the product is designed to be completed, but the final molding is done in a hot runner mold. In order to ensure a smooth product appearance at the end of the molding, the mold easily, those factors must be considered in the structural design of the products.Main Technique ParametersCavity/CoreMaterial718H, P20, NAK80, 2316, 2738, 2344Product MaterialABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc.BaseLKM or by requestedStructureDouble color injection mould, Solid Mould, Insert Mould, Mould with Slide, Mould with LifterRunner SystemHot runner, Cold runnerCavitySingle cavity, multi cavities by requested (support similar products in one mould)FinishCorrosion word, Mirror finish, BrushedLongevityAvailable SHOTS will depend on the steel material you chooseMould standardHASCO, DME, MISUMI, or by requested etc.SoftwareCAD, Pro-E, UG, etcDesign Time3-7 days after we receive your samples or your drawingsMain TechniqueMilling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc.Production time1-3 months, depends on mould structurePackingWooden case, or by requestThe flow chart to place a mould orderReceive inquiries from customersWe will send you quotation within 24 hours after inquiries confirmedCustomers need to offer samples or 2D/3D drawings and some details about the mouldConfirm the order (quality , price , material , delivery time , payment terms etc.)According to your requirement to prepare the productionClients confirm the details of the mouldSurface shapingDrill holes , high speed carve machine ,wire cutting , EDM, etc.Arranging the test mould and sending the samples to customersIf customers do not satisfy the samples, please give us advice to repairRepair , Polish , TextureWe will send samples to customers for confirmingDelivery by sea or by air ,etcWHY CHOOSE US YUESEN MOULDBelow are just a few reasons to do business with yuesen:- Sufficient experience in plastic mold design and manufacture- Outstanding teamwork- Constant technical innovation- High-quality, low-cost, trouble-free molds- Attentive after-sales services

Other supplier products

|

|

|

Mould name: Bowl Mould Shaping Mode: Injection MouldBowl Mold,Website:, Food container mold, Food container mouldMain Technique ParametersCavity/Co... |

|

|

|

Mould name:filter Mould Shaping Mode:Injection MouldPurifier Mold,Website:, Purifier Mould, filter Mold, filter Moulds, filter MoldingPurifier mold... |

|

|

|

Mould name:Bottle mould Shaping Mode:blow MouldBottle mold,Website:, Bottle molding, Blowing Bottle MouldBlow molding technology is mainly used for... |

|

|

|

Mould name:Fan Mould Shaping Mode:Injection MouldFan Mold,Website:, fan molds, fan moulds, fan moding, Fan MouldingFan mould sets, the key point is... |

|

|

|

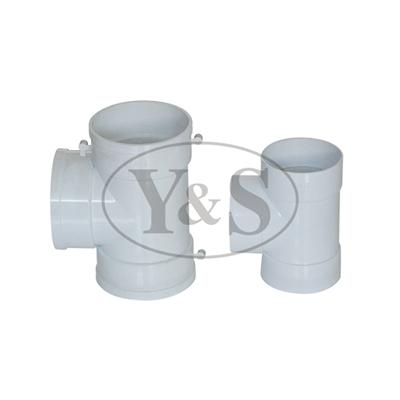

Mould name:Pipe Fitting Mould Shaping Mode:Injection MouldPipe Fitting Mold,Website:, pipe fitting moulds, pipe fitting moulding, Elbow Mould, Elbo... |

供应产品

Same products