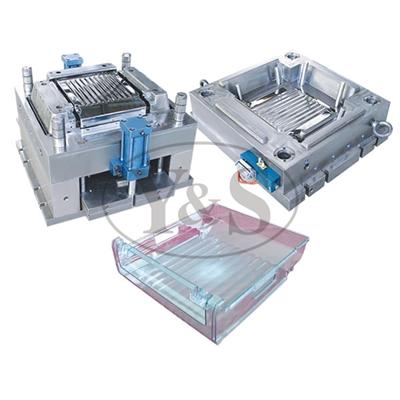

Microwave Mould

Mould name:Microwave Mould Shaping Mode:Injection MouldMicrowave Mold,Website:, Microwave Molds, Microwave MoldingMicrowave Mould and Microwave Ovens Mould manufacturing, door in mould labeling mould and in mould labeling parts supplying, most of our Microwave Moulds are offered to domestic market and we also offer Microwave plastic moulding service, we can cooperate with our customer for Microwave Ovens' plastic components moulding, we invest the moulds with the fixed min moulding quantities.Main Technique ParametersCavity/CoreMaterial718H, P20, NAK80, 2316, 2738, 2344Product MaterialABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc.BaseLKM or by requestedStructureDouble color injection mould, Solid Mould, Insert Mould, Mould with Slide, Mould with LifterRunner SystemHot runner, Cold runnerCavitySingle cavity, multi cavities by requested (support similar products in one mould)FinishCorrosion word, Mirror finish, BrushedLongevityAvailable SHOTS will depend on the steel material you chooseMould standardHASCO, DME, MISUMI, or by requested etc.SoftwareCAD, Pro-E, UG, etcDesign Time3-7 days after we receive your samples or your drawingsMain TechniqueMilling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc.Production time1-3 months, depends on mould structurePackingWooden case, or by requestThe flow chart to place a mould orderReceive inquiries from customersWe will send you quotation within 24 hours after inquiries confirmedCustomers need to offer samples or 2D/3D drawings and some details about the mouldConfirm the order (quality , price , material , delivery time , payment terms etc.)According to your requirement to prepare the productionClients confirm the details of the mouldSurface shapingDrill holes , high speed carve machine ,wire cutting , EDM, etc.Arranging the test mould and sending the samples to customersIf customers do not satisfy the samples, please give us advice to repairRepair , Polish , TextureWe will send samples to customers for confirmingDelivery by sea or by air ,etcWHY CHOOSE US YUESEN MOULDBelow are just a few reasons to do business with yuesen:- Sufficient experience in plastic mold design and manufacture- Outstanding teamwork- Constant technical innovation- High-quality, low-cost, trouble-free molds- Attentive after-sales services

Other supplier products

|

|

|

Mould name:filter Mould Shaping Mode:Injection MouldPurifier Mold,Website:, Purifier Mould, filter Mold, filter Moulds, filter MoldingPurifier mold... |

|

|

|

Mould name:Refrigerator Mould Shaping Mode:Injection MouldRefrigerator Mold,Website:, refrigerator moulding, fridge mould, ice box mould, refrigera... |

|

|

|

Mould name:Cap Mould Shaping Mode:Injection MouldCap Mold,Website:, Cap Moulds, Cap Moulding, cap molding, Cap injection moldCap mold design steps1... |

|

|

|

Mould name:Fan Mould Shaping Mode:Injection MouldFan Mold,Website:, fan molds, fan moulds, fan moding, Fan MouldingFan mould sets, the key point is... |

|

|

|

Mould name:Rice Cooker Mould Shaping Mode:Injection MouldRice Cooker Mold,Website:, rice cooker molding, rice cooker moldsRice Cooker Mould, top do... |

供应产品

Same products