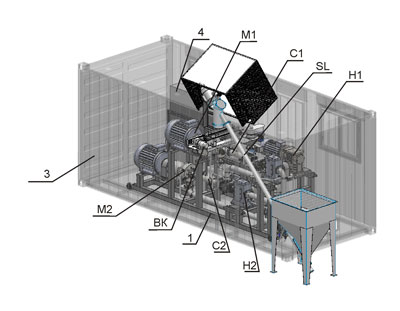

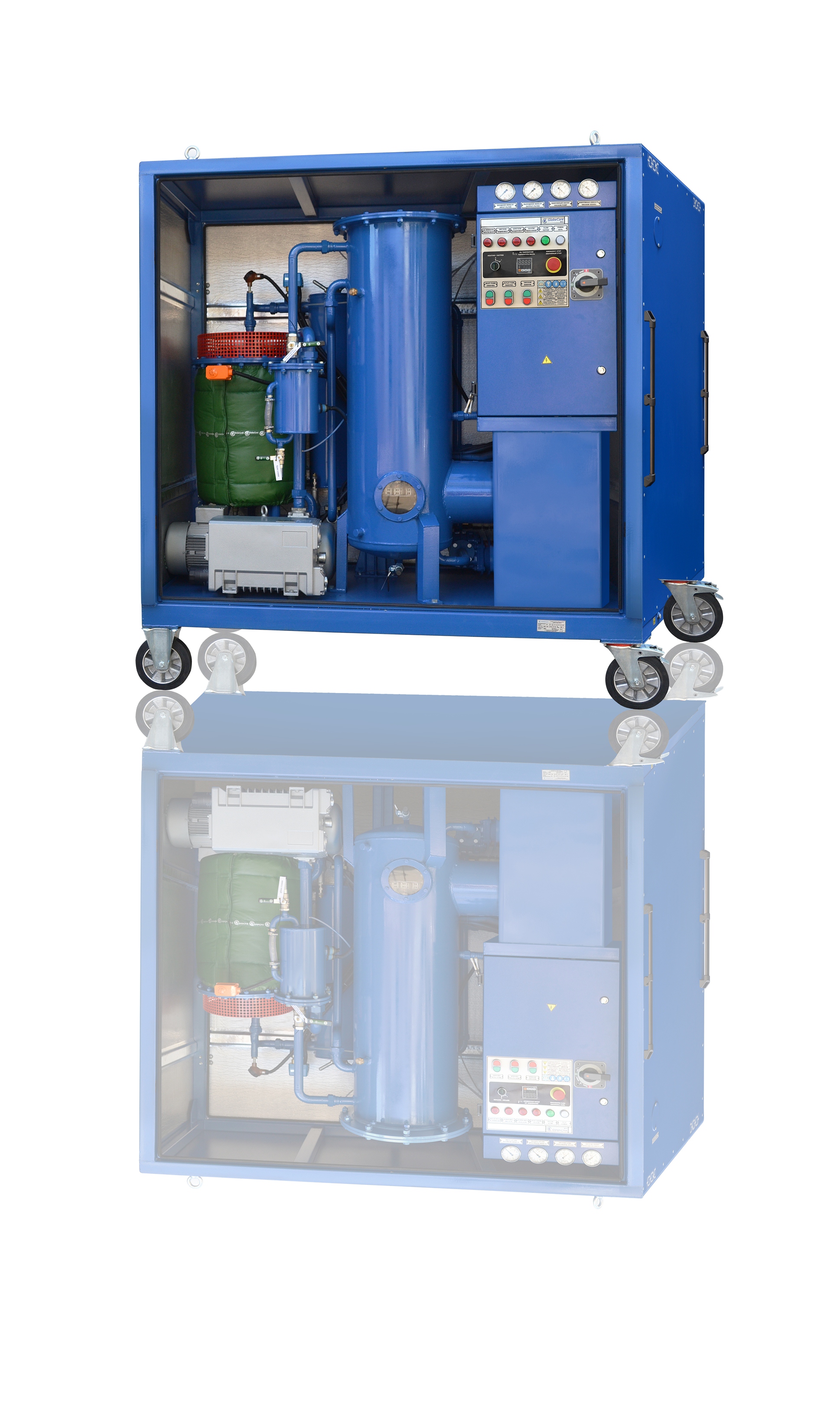

GlobeCore UMBP-22P capacity 22 m3 per hour

UMBP-22P bitumen modification unit is designed for production of modified bitumen, including polymer bitumen binding for preparation of top coat asphalt concrete, surface treatment of roads, protective layers for concrete, membrane type crack sealants, bitumen-elastomeric sealant mastics and roofing by mixing bitumen with polymers.

The unit may be operated either outdoors under canopy or indoors with forced ventilation. The unit may be operated in ambient temperatures from +5°Сto +40°С.

Specifications

Parameter

Value

1. Capacity, ton/hour, minimum 20*

2. Amount of polymer per 1m³ bitumen, kg 10…60

3. Amount of plasticizer per 1 m³ 10…100

4. Amount of adhesive additive per 1 m³ bitumen, liters (max) 10

5. Mode of operation Continuous

6. Nominalpower, kW

-mill 2х55=110

-bitumen pumps 2х18=36

-plasticizer supply pump 1.1

-adhesive additive supply pump 0.25

-screw conveyor drive 3

-weight conveyor and screw conveyor drives 0,43

-screw mixer drive 5.5

-total 157

7. Power

- voltage, V 380

- frequency, Hz 50

8. Dimensions (without assemblies removed for transportation), mm max

- length 6050

- height 2570

- width 3360

8. Max weight, kg 5860

*The performance specification were obtained when operating with power polymers Kraton-D, Kraton D-1107 and Kraton D-1192.

Performance specifications may vary if the unit is operated with the same polymers in pellets or other polymer products. Contact the manufacturer when selecting other polymers

Other supplier products

供应产品

Same products