high-temperature strength creep resistance Molybdenum Piercing Mandrel

With excellent high-temperature strength and creep resistance, TZM alloy can be used for manufacturing mandril ejectors of seamless steel pipe penetration machines. Molybdenum alloy ejectors are formed by adding rear earth materials into molybdenum powder raw materials through mixing, molding, appearance processing, high-temperature sintering and other processes, with the finished product denstity of more than or equal to 9.4g/cm³. Molybdenum ejectors are mainly applied to perforation of seamless steel pipes made of stainless steel, drill steel, bearing steel, high-temperature alloy steel and so on.

在线联系供应商

Other supplier products

| high melting point high-temperature strength good heat resistance Material for Die-casting Mold | Material-based Alloy for Tungsten-based Alloy and Molybdenum-based Alloy Die-casting Mold In the process of die-casting iron/steel materials, the o... | |

| high density no crack bright surfaces Molybdenum Target high purity | Molybdenum targets produced by Achemetal Tungsten & Molybdenum Co., Ltd. include molybdenum plane targets (molybdenum round targets and molybde... | |

| High density Higher machining property Molybdenum-niobium Target | Molybdenum-niobium targets produced by Achemetal Tungsten & Molybdenum Co., Ltd. include molybdenum-niobium plane targets and molybdenum-niobiu... | |

| hard high ductility small expansion coefficient high tenacity Tantalum | antalum has an extremely hard texture and the hardness of 6-6.5. Tantalum is a kind of rare metal with steel grey luster, and has the melting point... | |

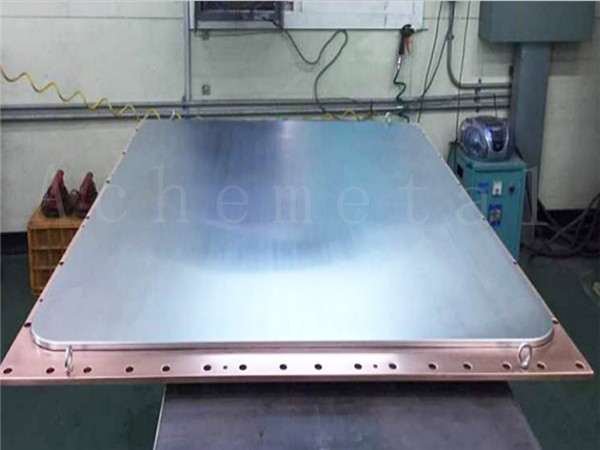

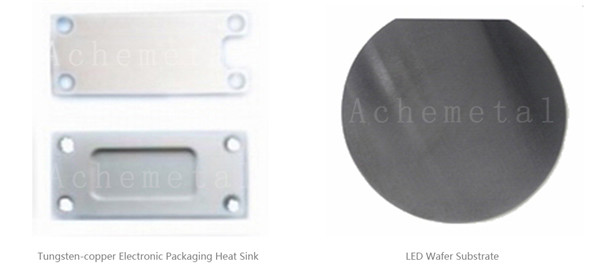

| Heat Sink Material stable operating temperature | With the development of electronic technologies, the heating of components has increasingly become a bottleneck of their functions and service life... |