water jet cutting stone plate

EAAK water jet cutter application:

Cutting materials are not limited (stainless steel, steel, copper, aluminum and other metals, glass steel, stone, glass, ceramics, plastics, composite materials...), waterjet cutting is currently the most applicable cutting process;

Metal cutting:

1 Decoration of stainless steel,aluminum.iron,brass and other metal cutting process.

2 Manufacture of machinery and equipment control cabinets such as food machinery,medical machinery,CNC machinery.

3 The metal parts cutting such as stainlesssteel flange,semi-finished,steel construction, non-ferrous metal and so on.

Glass cutting:

1 Gas stove surfaces, range hood,disinfecting cabinet, TV, bathroom products.

2 Construction and decoration glass,automotive glass.

Ceramic and stone cutting:

1 Ceramic cutting for decoration and construction.

2 Marble mosaic,granite mosaicmstone plate cutting.

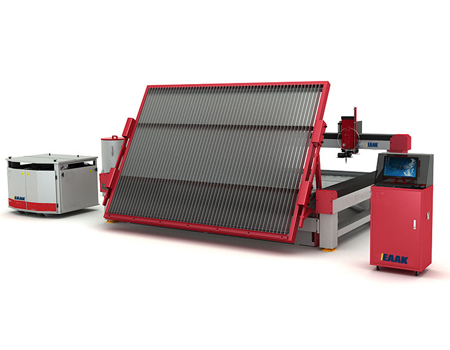

Feature of hydraulic lifting platform:

The lifting platform is specifically designed to solve the handling problems of large glass after processing. This platform can cut glass up to 4000 mm, the platform load is 1000 kg, the maximum angle of rotation is 85 degrees, and the hydraulic lifting method is adopted. After the glass is cut on the ordinary water cutter platform, especially after cutting a large number of irregular holes on the glass, the breakage rate of the glass during the process of glass uplifting is quite high, which is the most popular in the market. The cutting of tempered glass countertops is most obvious. Under the unanimous recommendation of the customers of glass deep processing, the glass cutting and turning platform has finally been successfully designed. At present, many problems have been solved for domestic and foreign glass deep processing customers, and the equipment has been well received by users.

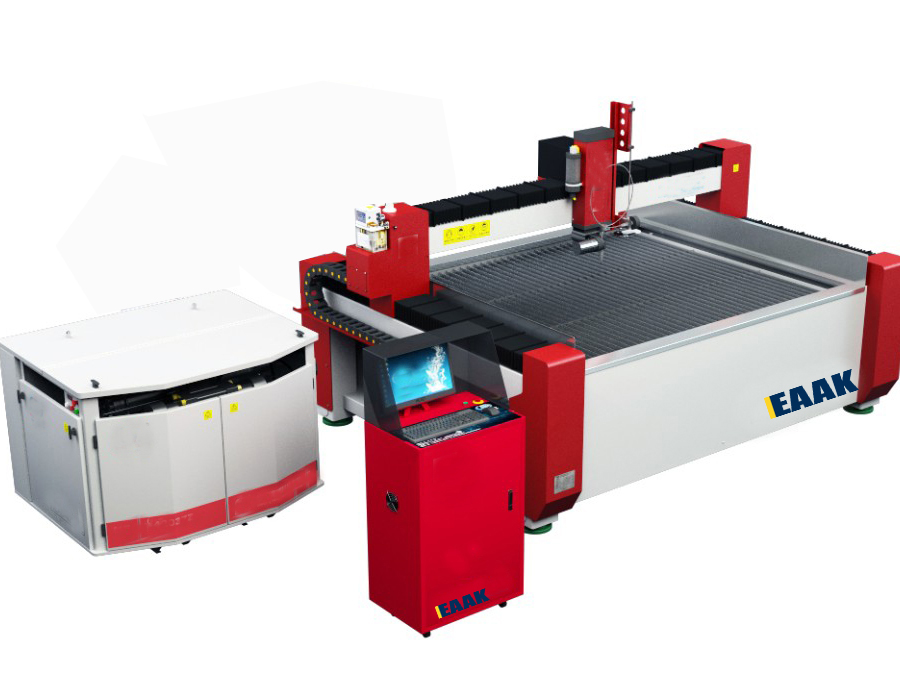

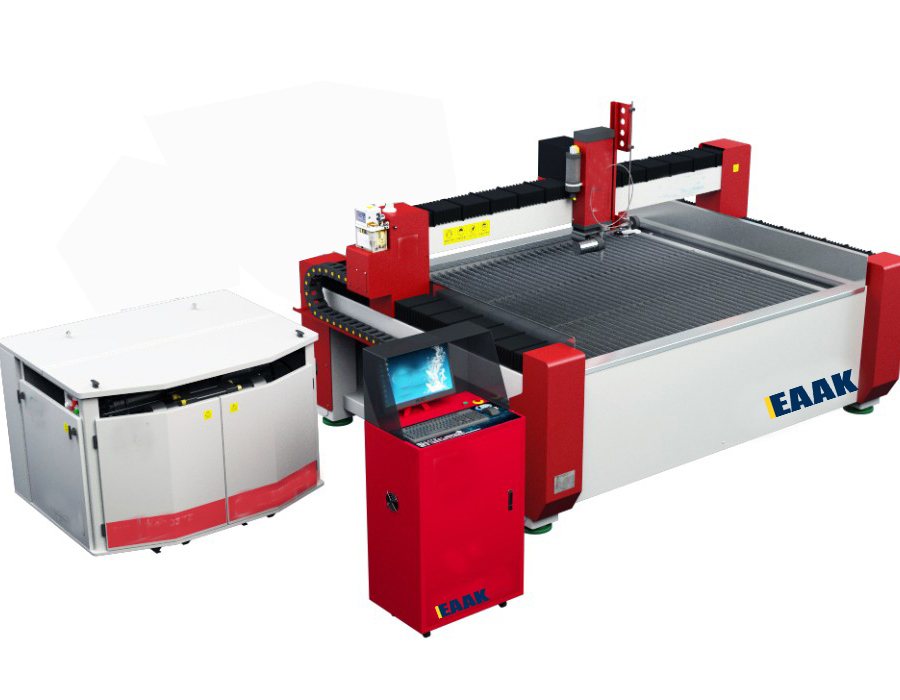

Specification of EAAKCNC water jet cutting machine:(as follows)

| Model |

EK3020R |

| X Y axis Working size |

3000mm*2000mm |

| Z working height |

150mm |

| Cutting Pressure |

380Mpa 30kw UHP pump |

| Control accuracy |

0.01mm |

| Cutting accuracy |

0.1-0.2mm |

| Repositioning Accuracy |

0.05mm |

| Max cutting thickness |

300mm(depends on materials) |

| Max. moving speed |

6000mm/min |

| Power supply |

380V 50Hz |

| Environmental temperature |

-10-50°C |

| Max flow rate |

3.7L/min |

| Max oil discharge |

206L/min |

| Max delivery capacity of oil pump |

106L/min |

| Control system |

Ncstudio (Shanghai) software IPC controller |

| CAD/CAM software |

AutoCAD,ArtCAM |

| Drive motor |

Japan Yaskawa servo drive motor |

Other supplier products

供应产品

Same products