Slewing Drive

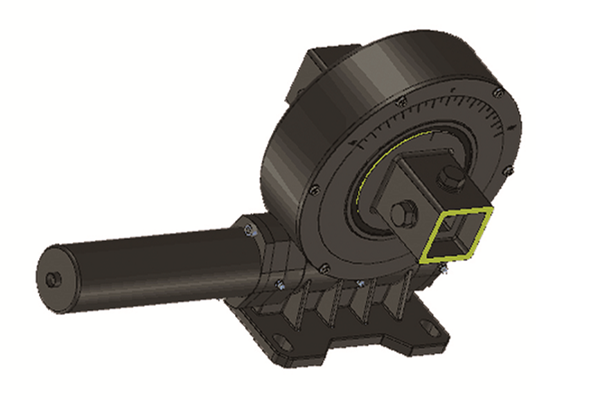

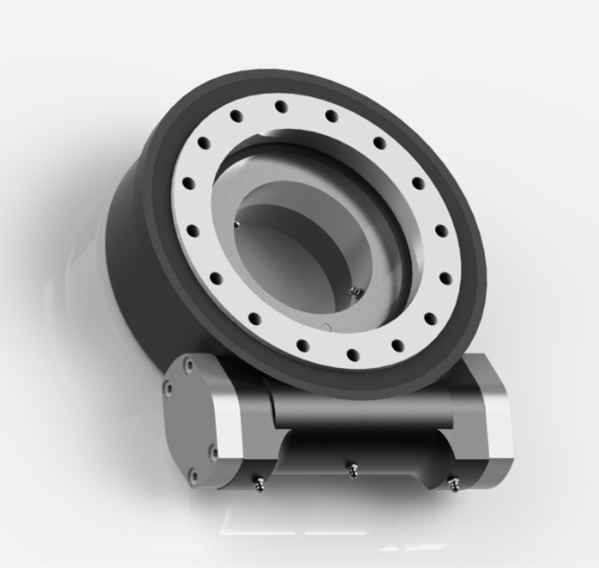

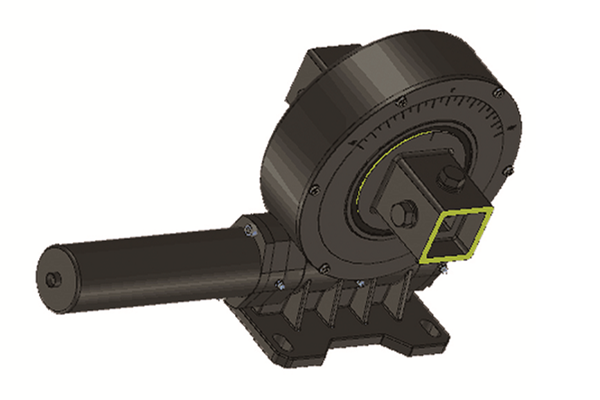

The worm gear slew driveis a full-cycle rotary reduction transmission mechanism integrated with a driving power source. The high precision bearingsareused as a transmission follower and a mechanism attachment member, and an active member and a driving source are attached to one of the inner and outer rings of the slewing ring. And the casing, and the other ring is regarded as both the transmission follower and the connecting base of the driven working part, so that the slewing bearing itself is a feature of the full-circle rotary connecting member, and the driving power source and the main transmission are efficiently configured. The part makes it a general-purpose reduction transmission mechanism that integrates the functions of rotation, deceleration and drive, while having a simple structure and convenient manufacture and maintenance.

According to the form of the variable speed transmission of the slew drives, it can be divided into a tooth type slewing drive and a worm gear type slewing drive, inheriting the respective characteristics of the gear drive and the worm gear drive, and the two slewing drives can be adapted to medium and high speed and low speed applications respectively. In terms of carrying capacity, the worm-and-worm type performs better than the gear type, and its load carrying capacity, deformation resistance and transmission rigidity are further improved when using an envelope worm drive, but the efficiency of the worm-gear type slewing drive is Inferior to the toothed rotary drive. According to the openness of the slewing drive transmission mechanism, the slewing drive can be divided into open type and closed type. Generally, the open structure is mostly used in applications where the environment is too harsh, the maintenance and maintenance cycle is short, and the open structure is more convenient for the machine. Inspection, maintenance and maintenance are also easier to replace. Closed structures provide a longer maintenance lifecycle where environmental conditions do not change much and are below the level of environmental pollution below medium.

As one of the most professional slew drive manufacturersin China, Maanshan Fuyong Intelligent Technology Co., Ltd. isspecialized in the manufacturing and development of slewing ring drivefor many years. We sincerely invite and welcome people from all around the world to invest and create more values together.

在线联系供应商

Other supplier products

| SE9 Helical Tooth Slewing Drive | To accommodate the rotation of the relative rotating structure, you can design the installation location parallel to the ground or with a few degre... | |

| Double Drive HSE25-2-2 Heavy Duty Vehicle Series | Slewdrivecan also be called slew drive gearbox. Most of our slewing ring driveis kind of worm gear reducer. And the slew ring bearing is a gear dri... | |

| VE Vertically-Mounted Slewing Drive-2019 | The VE Series Dual Axis SlewDrive is a vertical mounted design for low-speed (<1 RPM) outdoor applications. Its special structure effectively si... | |

| Slew Drive & Slewing Ring Bearing | Fuyong Intelligent is a leading manufacturer of slew drive and slewing bearing. Our products benefit from advanced technology, engineering experien... | |

| Double-Row Ball Type Slewing Ring | Double-Row Ball Slewing Ring The double row ball slewing bearingshas three races. The steel ball and the spacer block can be directly discharged... |

Same products

| Uratech : High-Quality CNC Tool Storage for CAPTO C3 holders | 卖方: Uratech USA Inc | Uratech: High-Quality CNC Tool Storage for CAPTO C3 holders When it comes to CNC tool storage, q... | |

| Mobile Counterattack All-In-One Machine | 卖方: Shanghai Dongmeng Road and Bridge Machinery Co., Ltd. | Stone Crushing Machine Factory Machinery Weight: 54-63t Max Feeding size(mm): ≤600mm | |

| Coaxial Wire Stripping Machine Automatic Rotary Stripping Machine Cable Harness Stripping Machine | 卖方: 816004 | 可编程同轴剥线机 概念:4806 是一款半自动同轴剥线机,适用于加工同轴、三轴、多芯和单芯电线。它采用最新的电子元件、用户友好的显示屏、精准的机械稳定性和卓越的剥线质量。该机器配备程序数据库和... | |

| Vinyl Exam Gloves | 卖方: 00000 | Vinyl Exam Gloves Powder Free Vinyl Exam Gloves are designed to provide a safe and economi... | |

| JN-IV850高效立式加工中心 | 卖方: 江南数控机床有限公司 | 加工灵活性,铣削、钻孔、攻丝等多种加工操作 高精度,高效率 发那科系统、三菱系统、西门子828D系统三种选择,标配原厂电机; 针对产品加工,可选择皮带式或直联式 |