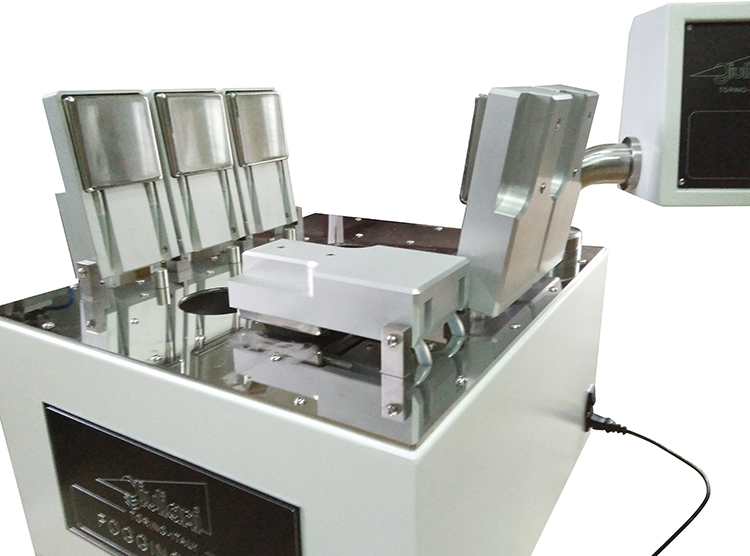

Tracking index tester

Introduction

The electric tracking index test is performed on a surface of a solid insulating material by applying a voltage to a platinum electrode of a predetermined size (2 mm x 5 mm) and dropping a predetermined volume of conductive liquid (0.1% NH 4 Cl) at a predetermined height (35mm) for 30 seconds, to evaluate the electric leakage resistance performance of the surface of a solid insulating material under the combined influence of an electric field and a wet or contaminated medium.

Tracking index tester rigorously is a professional inspection tester, designed and manufactured based on GB4207, IEC60112 and other standard, to measure the comparative tracking index and proof tracking index in the simulated wet condition, with characteristics of simplicity, accuracy, reliability, practical feature, etc.

Application

Tracking index tester is suitable for the research, production and quality inspection departments in the industry of lighting equipment, low-voltage electrical appliances, household appliances, machine tools, electrical machine, electric tools, electronic instruments, electro technical instruments, information technology equipment, as well as insulating materials , engineering plastics, electrical connectors, accessories industry.

Technical Parameters

1.The chamber is paint spray procced, elegant and anti-corrosive, size:1200mm X 600mmx 1200mm.

2.All specimen holders are made by stainless steel material.

3.Equipment consists of the voltmeter, ammeter, delay overcurrent relay, power supply, circuit control system, button switch, signal lights and other components.

4.Automatic drip device contains drip tube, drip nozzle, counting device, drip counting device, drip control device, droplet volume measuring tool, etc.

5.Drip nozzle device can adjust; Adjust height 30 to 40 mm, ensure the drip position between the two electrodes .

6.Electrode device contains platinum electrode, electrode fixing device, 4 mm gauge, etc. The electrode is adjustable and detachable.

7.Electrode is 5 mm wide, 2 mm thick, 99.9% purity of platinum, 30 ~ 60 degrees sharp tip.

8.Electrode pressure to the sample can be adjusted. The adjusting range is 1.00 N (+ / - 0.001 N), electrode distance 4.0 mm + / - 0.01 mm, intersection Angle 60 ° + / - 5 ° .

9. Equipped with sample stage

10.Equipped with glass plate: thickness≥4mm

11. Equipped with electrolyte:1 bottle of ammonium chloride and 1 bottle of alkyl naphthalene sulfonic acid sodium reagent.

12.Test voltage: 0 ~ 1000 v adjustable and digital display. Maximum error of voltage meter display value is 1%.

13. Short circuit current: (1 ±0. 1), A voltage drop value less than 10% .

14.Test current over 0.5 A lasting more than 2 seconds, the system automatically shut down the equipment.

15.Safety door control system: when the door is opened, the test system will not work.

16.Electrode: 5 mm x 2 mm rectangle platinum electrode and brass electrode each one pair, in accordance with the size requirements of IEC60112 figure B. 1.

17.The intersection angle between electrodes is 60 °±5 °, spacing of 4±0.1 mm.

18.Electrode pressure to sample is 1. 00N±0.05N.

19.Drip system: (30±5) seconds (drip initiation of 29.8 S + drip time duration of 0.2 S),

Other supplier products

|

|

Filter Tester MFP Nano Plus 4000 |

MFP Nano Plus 40000 with U-SMPS Real-time determination of fraction separation efficiency with two UF-CPC in raw and clean gas;MFP filter test rigs... |

|

|

Face Mask Field of Vision Tester |

TRANSLATE with x

English

Arabic

Hebrew

Polish

Bulgarian

Hindi

Portuguese

Catalan

Hmong Daw

Romanian

... |

|

|

Fogging tester |

Brief Introduction:The fogging tester used to test the properties under certain environmental conditions for leather and fabric fogging phenomenon... |

|

|

Leather Softness Tester |

TRANSLATE with x

English

Arabic

Hebrew

Polish

Bulgarian

Hindi

Portuguese

Catalan

Hmong Daw

Romanian

... |

|

|

Curl elasticity detector |

TRANSLATE with x

English

Arabic

Hebrew

Polish

Bulgarian

Hindi

Portuguese

Catalan

Hmong Daw

Romanian

... |

供应产品

Same products