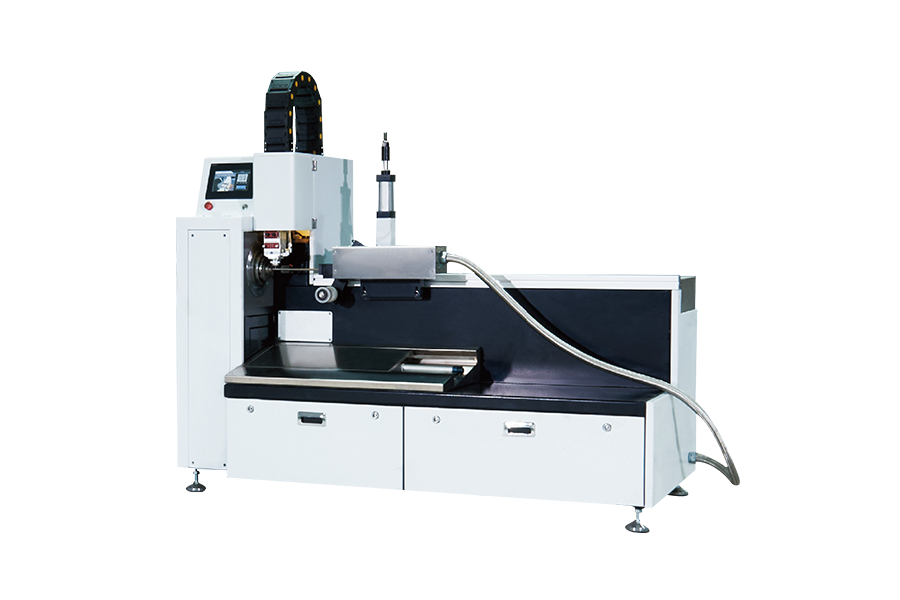

Features and Advantages:

- Focus on thin metal sheet cutting that less than 8mm thickness.

- Compact structure, reliable and cover an area of an area small.

- Suit many varieties of small, middle batch and mass production.

- Humanizing design, convenient operation. Just to finish CAD drawing with computer, save processing time and cost.

- High performance price ratio, low operating The cost is only 1/8 of the same kind of co2 laser cutting machine, and maintenance costs only 1/10.

- High precision serve motor, lead screw and guide ways imported ensure the efficiency and accuracy, increasing the stability and reliability greatly.

- High cutting efficiency and quality, no noisy. Cutting speed is 100 times larger than the EMD wire cut. Small heat influence area, cutting seam smooth and no deformation, post treatment is not needed.

|

CNC Laser Cutting Machines Series Model:

- SD-YAG1212 Laser Cutting Machine (cutting area:1200X1200mm)

- SD-YAG2513 Laser Cutting Machine (cutting area:2500X1300mm)

- SD-YAG3015 Laser Cutting Machine (cutting area:3000X1500mm)

Laser Metal Cutting Machine Application:

Application Materials: CNC Laser Cutting Machine is good at cutting various metal sheets: Stainless Steel, Mild Steel , Carbon Steel , Alloy Steel , Spring steel , Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Sheet, Copper Plate, Brass Plate, Bronze Sheet, Gold Plate, Silver Sheet, Titanium Plate, Metal Tubes and Metal Pipes, etc.

|

Application Industries: Soullon Metal Laser Cutting Machine are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

|

Quality Control:

We always pay more attention to the quality of laser cutting machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser powermeter. In the mechanical assemble process, the laser interferometer, laser callimator, dial indicator and marble plate are used; In the laser assemble process, the laser powermeter and optical microscope are adopted.

After-sale Service:

- Technical support online service provided.

- Technical files service provided.

- On-site training service provided.

- Spare parts replacement and repair service provided.

|

|