High efficiency rotary feeder for conveying

The Rotary Feeder / Rotary valve / airlock introduces material into the conveying system at highest volumetric efficiency when material flow into the feeder is controlled to permit free venting. The feeder may be used under a head of material when appropriate aeration is provided to create a path for relief of the reverse air flow. In operation, air enters a single inlet and passes into the rotor pocket through two (2) ducts integrally cast in the end plates, assuring complete fluidization and discharge. High efficiency is attained through the combination of gravity and air-sweeping of the fluidized material into the conveying line. This design principle assists greatly in discharging materials which have a tendency of hanging up in the rotor pockets. The rotary feeder permits the use of smaller sized components and related equipment in pressure pneumatic conveying systems resulting in savings in initial equipment cost, installation cost and space requirements.

在线联系供应商

Other supplier products

| High efficiency mills for mining industry | ML Series Vertical Roller Mill is large size Powder Grinding Machine that designed and manufactured by our company. Its technology is origin from ... | |

| Mining-ore flotation multistage centrifugal blowers | Valuable minerals in ore can be separated from each other and from worthless components by the froth flotation process. Flotation is a key process ... | |

| Forced oxidation turbo blowers for FGD | Flue Gas Desulphurization Systems remove sulfur dioxide from coal or other sulfur containing fuels. Roots type blowers or centrifugal blowers provi... | |

| Mechanical seals gas blowers for special applications | EURUS blowers apply different michanical seals to diliver different gas. mechanical seals include: Cartridge, single spring, labyrinth, magnetic la... | |

| Forced oxidation Roots type blowers for FGD | Flue Gas Desulphurization Systems remove sulfur dioxide from coal or other sulfur containing fuels. Roots type blowers or centrifugal blowers provi... |

Same products

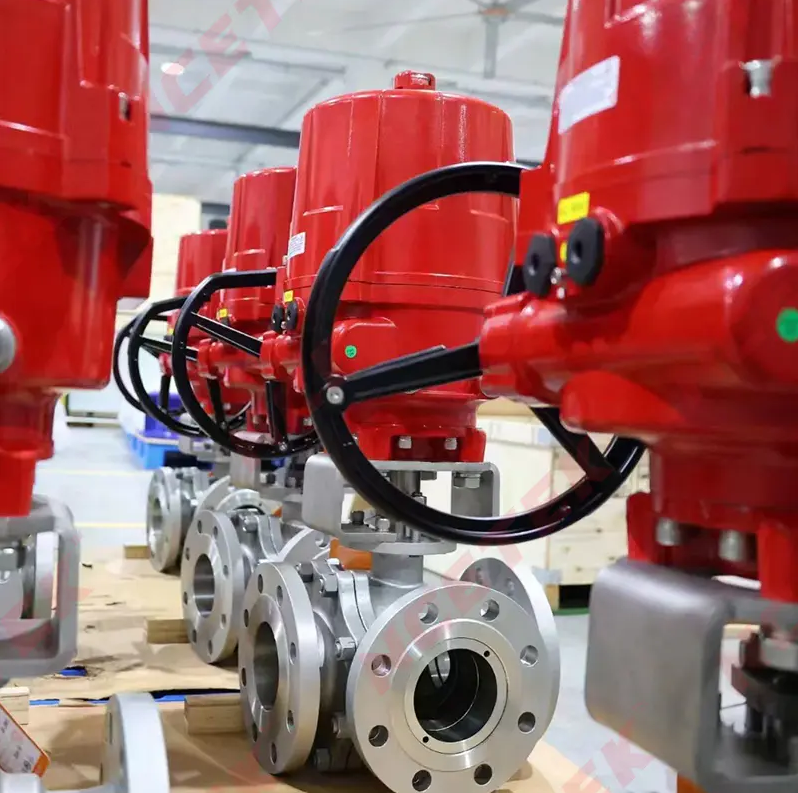

| 中国三通球阀工厂 | 卖方: Zhejiang Naishi Valve Co. | 技术规格◎设计标准:API6D、ASME B16.34、GB/T 19672等◎材质:碳钢、不锈钢、合金钢◎公称尺寸:2"~24"DN50~600◎公称压力:CLASS150LB~2500LB ... | |

| Qianli千里超级相机 Ai Gorilla 4K 相机及巴洛镜套装 Super Camera Ai Gorilla 4K Camera with Barlow Lens Kit | 卖方: 深圳市维客修科技有限公司 | 该套件的核心功能是提供超高清、宽视野、长工作距离的图像,从根本上提高手机维修技术人员的工作流程和效率。 | |

| Displacement Sensor 6000TDGN Raj West Lignite power | 卖方: Dongfang Yoyik Engineering Co., Ltd | ||

| 钙锭切屑机 | 卖方: 濮阳市名利石化机械设备制造有限公司 | 我们有钙锭切屑机和铝锭制粒制粉生产线。该生产线由钙锭切屑机、造粒机(制粒机/磨机)组成。切屑机将钙锭切成屑,造粒机将屑磨成颗粒或粉末。您可以根据需要购买设备或生产线。 | |

| Hirschmann MACH102-8TP 943 969-001 Switch | 卖方: 840499 | The MACH103-8TP is a fanless 19-inch rack mount Managed Modular Fast Ethernet Layer 2 Industrial ... |