Automated Travelling Head High Frequency Welding Machine

Equipment Description of Automated Travelling Head High-Frequency Auto Welding Machine

Automated traveling head high-frequency welding machine, specializing in the production of architectural stretch film structure, tents, truck tarpaulins, PVC oil tanks, large advertising clothes, fast doors, swimming pool liners & covers, large inflatable models, airline hangars and so on. Special pulse welding can be used as auxiliary weldings such as for non-HF weldable fabrics such as PE and PP.

The stroke of automated traveling head high-frequency welding machine can be selected from 3m to 100m. Continuous welding is performed automatically within the traveling range. The precision of the knife can be controlled within 1mm. On the touch panel of the control panel, the position of the press welding head is constantly displayed, and the welding head can automatically return to the end of the stroke.

There are two walking tables on the back of the press. The operator can operate the machine with the press.

The functional description of Automated Travelling Head High-Frequency Welding Machine

PLC and color touchscreen control

Multiple sets of process parameters can be pre-stored for different materials and products and can be called at any time.

The highly sensitive spark protection circuit

Intelligent high-frequency power adjustment is achieved.

Automatic lifting of molds by the pneumatic system

Humanized design with station lighting

The table is designed with negative pressure adsorption to prevent material slippage.

The press moves along the precision linear slide to ensure high-precision operation.

The machine can be controlled in multiple positions with a control box on both sides and a workstation.

The help we can provide:

Warranty 12 months

We believe that the best after-sales service does not require after-sales service, and strive to improve the quality of equipment. All efforts to make products safe, comfortable and trouble-free.

Perfect protection circuit to avoid the damage to molds and workpieces

Certificates available: CE, ISO9001, CSR, High-Frequency Electromagnetic Radiation Monitoring Report

|

Oscillatingpower: |

10/15/20/25-35kW |

|

PowerSupply: |

15/22/30/38-45Kkva |

|

Weldingsurface: |

400-1200cm2 |

|

Mainfuse: |

32/40/50A |

|

Operatingfrequency: |

|

|

PowerSource: |

3x400V;50Hz |

|

Powertube: |

Air-cooledcermettransistor |

|

FireProtection: |

UltrafastNanosecondSolidStateAntiFlash™System |

|

Automaticadjustment: |

ATSTMautomatictuningsystem |

|

PLCControlSystem: |

10"TouchScreenHMI |

|

Electro-pneumaticpress(in0.1-0,8MPa): |

260-2400kg |

|

Electrodepneumaticpress(0.8MPa): |

1600/2400kg |

|

Electrodelength: |

1500mm(optional1700mm) |

|

Electrodestroke: |

upto160mm(abilitytostopatanyheight) |

|

Tablelength: |

upto100m,800mmsection |

|

Slotwidth: |

600x400mm-standard |

|

Tablewidth(withoutslots): |

800mm |

|

Spacebehindtheelectrode(withgroove): |

1000mm |

|

ElectrodeMounting: |

QuickControl,Pneumatic |

|

Groundpin: |

standard,pneumaticdrive |

|

HFweldingheaddrive: |

automatic,variablefrequencycontrolmotor;linespeedupto0.5m/s. |

|

Size(lengthxheightxwidth): |

1970x1700x5400/8000mm |

|

Weight: |

1300kg |

Liaoning Unify High-Frequency Equipment Co., Ltd is a renowned Chinese company specializing in R&D and high frequency welding machine suppliers, high and medium frequency induction heating equipment and fully solid state equipment. Welcome to order from expert high frequency welding machine manufacturer in China.

Our HF welding machines are extensively applied in manufacturing automobile interior trims and inflatable products, welding PVC, drying timber and insulation paperboard, etc. The quality management of our company is in conformity with ISO9001:2000 and our products are CE certified. To co-operate with us guarantees that you will get the best equipment with affordable price. Tieling Yufei High-Frequency Equipment Co., Ltd is looking forward to providing the best service for you.

在线联系供应商

Other supplier products

| Explore More HF Welders Products | Equipment Description of High Frequency PVC Door Curtain Welding Machine UNIFY's consistent superior quality has been upheld. The width of fully au... | |

| Medical Bags Welders | Liaoning Yufei high-frequency welding equipment co,.ltd has been developing and manufacturing machines for the medical industry for over 60 years. ... | |

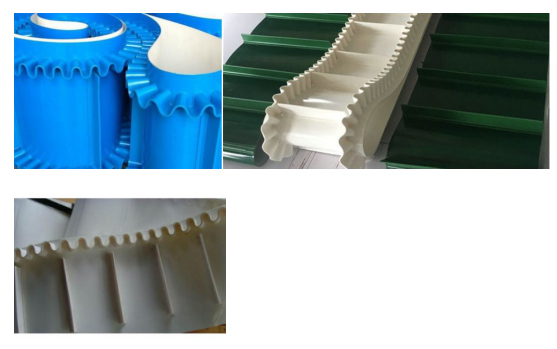

| Industrial Belt Welder 2049 | Are you looking for rf welding supplies? We have rf welder for sale! Mainly application of Industrial Belt Welder Used for industrial belt skirt ... | |

| Water Guide Heat Welding Machine | Equipment Description of Water Guide Pulse Welders The pulse heat sealer is a semi-automatic advanced heat pulse sealer used for welding various te... | |

| High Frequency Dryer For Insulation Cardboard 2019 | It is an advanced process method to dry and mold the insulated board with the high-frequency electric field. This production method has many obvio... |

Same products

| Heavy Equipment Tire Chains | 卖方: Zhejiang Pujiang Bohu Chain Stock Co., Ltd. | Introducing our Heavy Equipment Tire Chains, the ultimate solution for enhancing traction and sta... | |

| 2BV6161 Liquid Ring Vacuum Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | 2BV series liquidring vacuum pumps are suitable for pumping the gases and steam. Its suction pres... | |

| 2BV6121 Liquid Ring Vacuum Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | 2BV6121 Liquid Ring Vacuum Pump2BV series liquidring vacuum pumps are suitable for pumping the ga... | |

| 2BV6111 Liquid Ring Vacuum Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | 2BV6111 Liquid Ring Vacuum Pump2BV series liquidring vacuum pumps are suitable for pumping the ga... | |

| 2BV5161 Water Ring Vacuum Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | 2BV5161 water ring vacuum pump2BV series liquidring vacuum pumps are suitable for pumping the gas... |