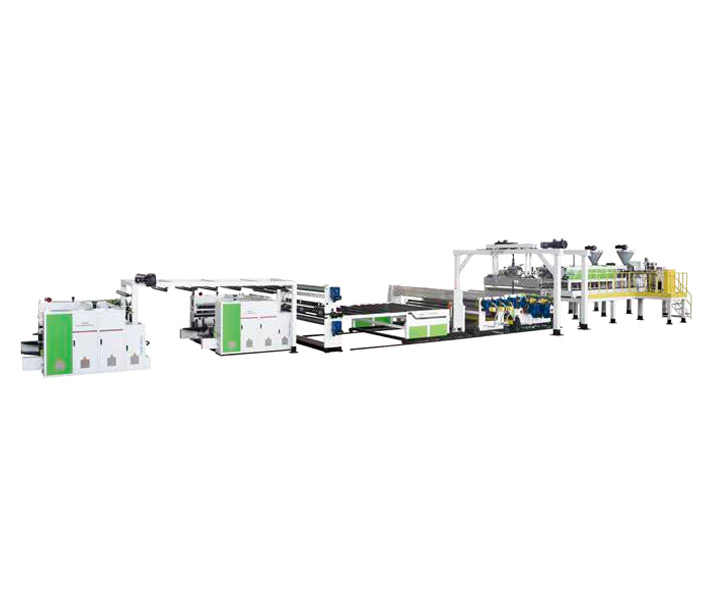

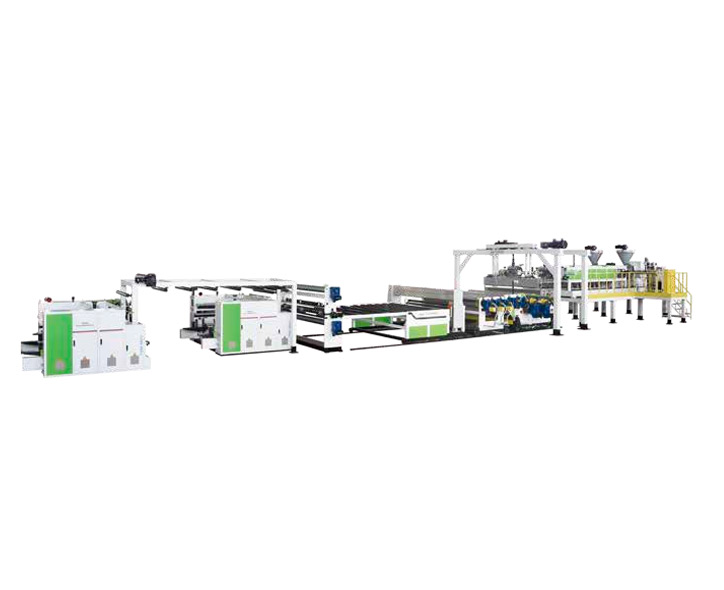

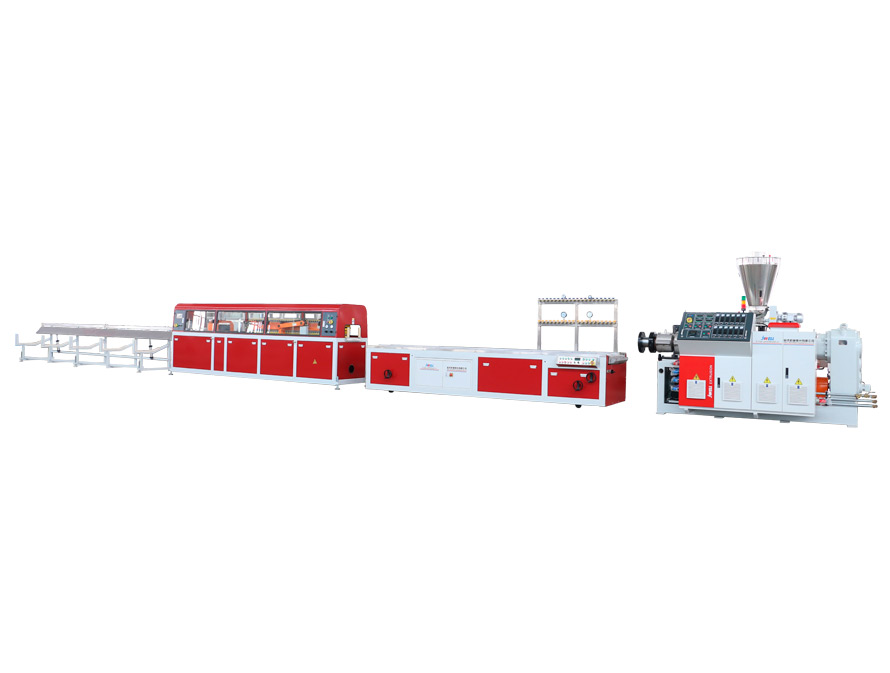

Film Extrusion Line

We have own experimental institution and professional company to research and develop high-performance plastic film extruder machine. The main film production lines include EVA, POE photovoltaic film extrusion line, PVB, SGP glass interlayer film extruder machine, TPU film extrusion line, PE breathable film extrusion line, cast film extrusion line, stretch film and medical film extrusion line. Based on the proven JWELL extrusion technology, the core processing components(screw, barrel, mold, machine frame, metal heating treatment and other spare parts) have been newly designed and produced by our own professional factory. Our screw&barrel manufacturing company has been founded in 1978, and produced the first high-quality screw in China at that time, also has been the famous and reliable brand in the market.

What Are the Production Technologies of Plastic Film?

The complete film extrusion production process includes: mixing raw materials and additives, feeding, single screw plasticization, change screen, extrusion, roller forming, cooling, traction and cutting. As one of film extrusion companies, we choose famous roller and special designed screw for precise production.

What is the Difference Between Blown Film and Cast Film?

The film blowing process is mainly divided into two forms: upper blowing cooling and lower blowing cooling. In terms of appearance, the cylindrical film is the main performance feature, and the tensile strength is better than that of the cast film. The casting method is mainly composed of multiple extruders, multiple channel distributors, T-die, casting system, horizontal traction system, oscillator and winding system. The main characteristics are that the produced film products have good surface gloss, high flatness, small thickness tolerance, good mechanical elongation, good flexibility, and higher transparency than blow molding.

How Do You Improve Plastic Film Production?

As we all know that uniform film thickness and smooth surface are very important for good quality film. Before production, we need to choose good extrusion machine firstly, including special screw structure, precise temperature control system, high quality rollers and experienced technology. If you need these help, please contact us at any time.

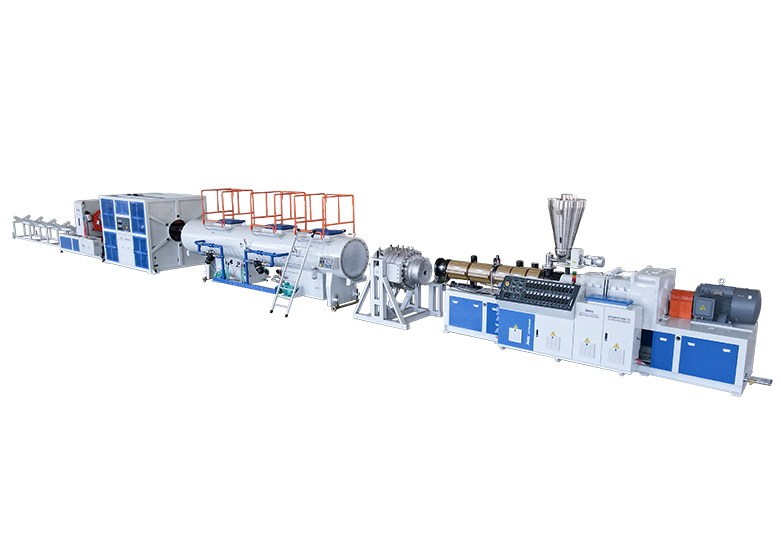

As a reliable china extruder supplier, we can offer different kinds of plastic pipe extruderfor sale with great prices, anything you need, please contact us.

在线联系供应商

Other supplier products

| Film Extrusion Line | We have own experimental institution and professional company to research and develop high-performance plastic film extrusion machines. The main fi... | |

| Pipe Extrusion Line | As a pipe extrusion line supplier, Jwell offers different types pipe extrusion machine to meet production for various pipes with different applicat... | |

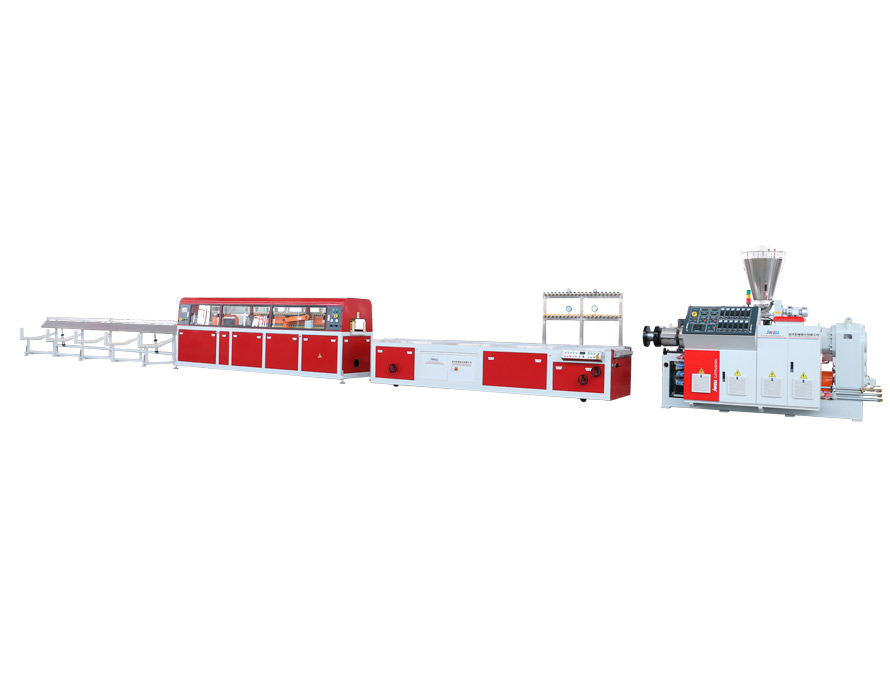

| PVC Ceiling Panel Extrusion Line | We've focused on providing good quality PVC ceiling panel extrusion line / pvc ceiling extrusion line for over 25 years since 1997, and have accumu... | |

| PVC Wall Panel Extrusion Line | PVC Wall Panel Extrusion Line JWELL Machinery specializes in complete solutions for various PVC wall panel extrusion lines, from plant planing to ... | |

| PVC Ceiling Panel Extrusion Line | We've focused on providing good quality PVC ceiling panel extrusion linefor over 25 years since 1997, and have accumulated rich experience and matu... |

Same products

| High Vacuum Pump 2be 203 Series Water Ring Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | Application scope and characteristics: Greentech International (Zhangqiu) Co., Ltd is the profes... | |

| Advanced technology Electric regulating valve T967H-64 for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Advanced technology Electric regulating valve T967H-64 for thermal power plant The use of advanc... | |

| High Security Superheater outlet plug valve SD61H-P54.5150V for power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High Security Superheater outlet plug valve SD61H-P54.5150V for power plant Deyang YOYIK is a st... | |

| "Low Failure Rate Bellows valves WJ10F-1.6 for power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Low Failure Rate Bellows valves WJ10F-1.6 for power plant Deyang Dongfang Yoyik is a trade produ... | |

| Customized Check valve H42H-16C for power station | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Customized Check valve H42H-16C for power station Our company is equipped with high-precision cu... |