Pillow Block Bearing

Pillow block bearing is an independent bearing unit that can provide support, load, and fix functions, and reduce friction resistance. Pillow block bearings are generally a unit composed of gray cast iron, ductile cast iron or cast steel bearing housings, rolling bearings and related sealing structures, fasteners, etc.

Pillow block bearing generally has a sealing mechanism and is filled with an appropriate amount of grease to ensure the normal operation of pillow block bearing during the lubrication cycle, and can provide relubrication oil injection holes.

Pillow block bearings are generally divided into two types, intergrated type and split type, which can be selected according to different installation occasions and requirements. The split bearing housing(also called as plummer blocks) is of upper and lower halves, and the bearings in the bearing housing also have a split type or an integral type.

The types of pillow block bearings include ball bearings, roller bearings and tapered roller bearings, etc., depending on the load and work requirements.

The fixing method of pillow block bearing and the shaft generally adopts a set screw, an eccentric sleeve, etc.

Plummer Block

The plummer block is a kind of large and extra-large bearing seat that can stand comprehensive loads and has a special structure. It has the characteristics of compact structure, sensitive rotation, and convenient device maintenance.

Pillow Block

Vertical housing ball bearing unit/flange housing ball bearing unit/vertical housing roller bearing unit/flange housing roller bearing unit

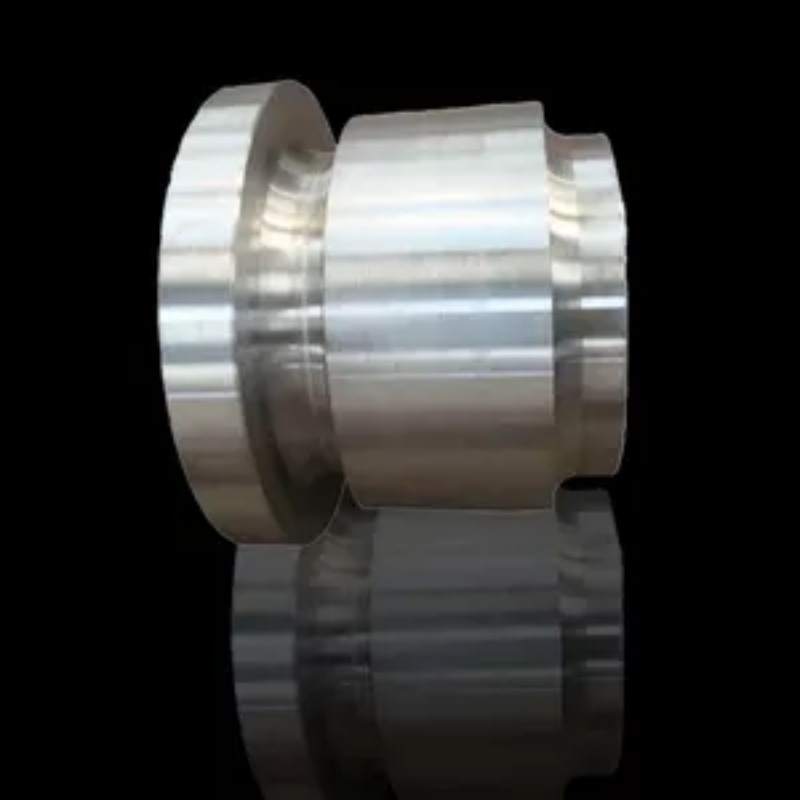

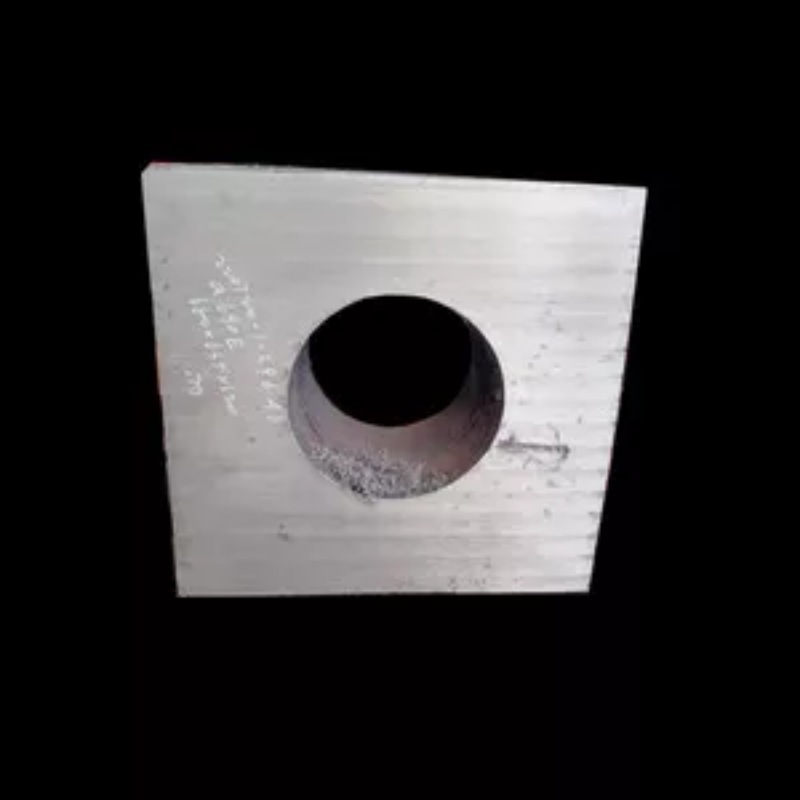

Special Housing / Pillow Blocks With Different Material

Pillow block bearing is a kind of bearing unit that combines rolling bearing and bearing housing/blocks. Most of the insert bearings are made of spherical outer diameter and installed together with housings/blocks with spherical inner holes. They have various structural forms, with good versatility and interchangeability.

How to Choose Pillow Block Bearing?

Shaft diameter or bore of pillow block bearing: calculate the loads according to the customer's selection, and determine the shaft diameter or the bore of pillow block bearing with sufficient rigidity and deflection.

Shaft height position: Determine the height of the shaft center from the mounting base of pillow block bearing according to the structure size of the mechanism.

The shaft maximum speed: According to the working speed of the shaft, THB, as a professional pillow block bearing supplier, determines whether the limit speed of the bearing with a seat can meet the application requirements.

The maximum load of the pillow block bearing: According to the load of the entire shafting system, the load of pillow block bearing would be verified, including the fatigue life of the bearing and the strength of the pillow blocks.

Misalignment performance: According to the misalignment information required in the shafting design, select the appropriate type and configuration of pillow block bearing.

The Installation of Pillow Block Bearing

Mounting steps for pillow block bearing:

Check whether the position tolerance of the connecting hole at the mounting position of pillow block bearing and the flatness of the fixed base surface of pillow block bearing meet the requirements.

Clean pillow block bearing and pillow block bearing to be installed on the base position and the surface of the shaft with a cleaning agent to keep the surface free of impurities and dust, and coat the surface with a layer of anti-rust oil.

Install the shaft into the bore of inserted bearing, during the installation process, only use tools such as a rubber hammer or nylon rod to strike the end face of the insert bearing's inner race to move, and do not strike other positions of other bearing housings.

After pillow block bearing is installed in the proper position of the shaft, fix pillow block bearing on the base, and tighten the bolts according to the specified torque requirements.

After installing the pillow block bearings at both ends, the shaft should be able to move axially between the bearing holes with a certain amount of force, which can ensure good alignment of pillow block bearing at both ends. Otherwise, it is necessary to reposition and adjust pillow block bearing.

Use appropriate torque to alternately tighten the eccentric sleeves on the inner ring of the bearing at both ends to ensure that the bearing is firmly fastened to the shaft.

As a bearing exporter, we will offer types of high quality products for sale, if you are interested, please contact us.

在线联系供应商

Other supplier products

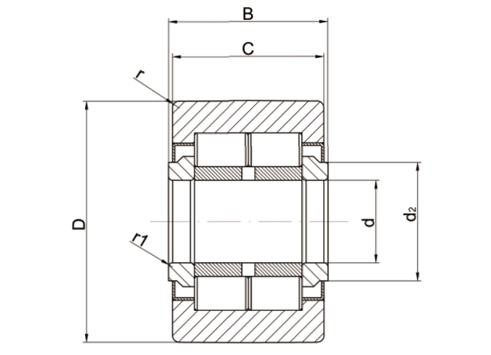

| NUTR 17 Support Roller | Specifications of NUTR 17Support Roller Item NUTR17 (Mass) m≈g 147 Dimensions D 40 ... | |

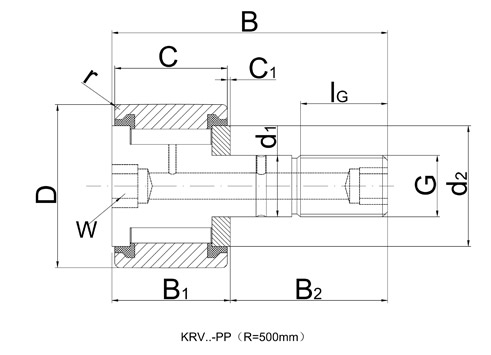

| KRV 30 PP/ CF 12 VBUUR Cam Follower | Specifications ofKRV 30 PP/ CF 12 VBUURCam Follower Designation KRV30PP CF12 VBUUR (Mass)m&... | |

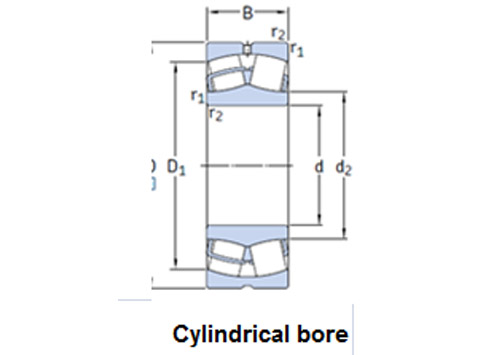

| 24148 CC/W33 Spherical Roller Bearings | Specifications of 24148 CCW33Spherical Roller Bearings Designations (Bearing with cylindrical bore) 24148... | |

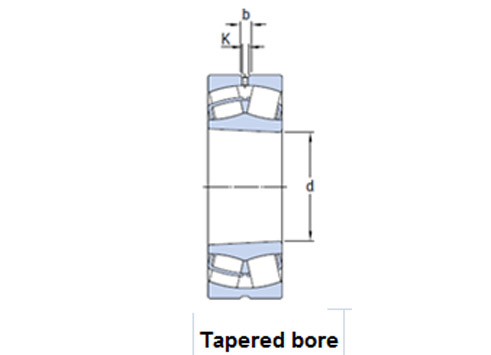

| 22211 EK Spherical Roller Bearings | Specifications of 22211 EKBearings Designations (Bearing with tapered bore) 22211EK Principal dimensions (mm) d 55... | |

| Pillow Block Bearing | Pillow block bearing is an independent bearing unit that can provide support, load, and fix functions, and reduce friction resistance. Pillow block... |

Same products

| Drum Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Drum Forging Drum Forging Brand origin: Runchi shandong Processing ability: turning, milling, pla... | |

| Wheel Hub Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Wheel Hub Forging Wheel Hub Forging Main features: [Manufacturing Standards] Strictly produce for... | |

| Nozzle Forging Nozzle | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Nozzle Forging Nozzle Forging Brand origin: Runchi shandong Processing ability: turning, milling,... | |

| Marine Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Marine Forging Marine ForgingMain features: [Manufacturing Standards] Strictly produce custom f... | |

| Bearing Housing | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Bearing Housing Product Name: Bearing housingBrand origin: Runchi shandong Processing ability: ... |