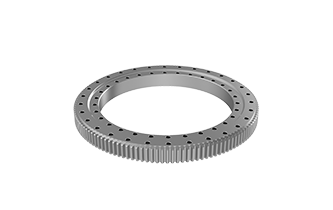

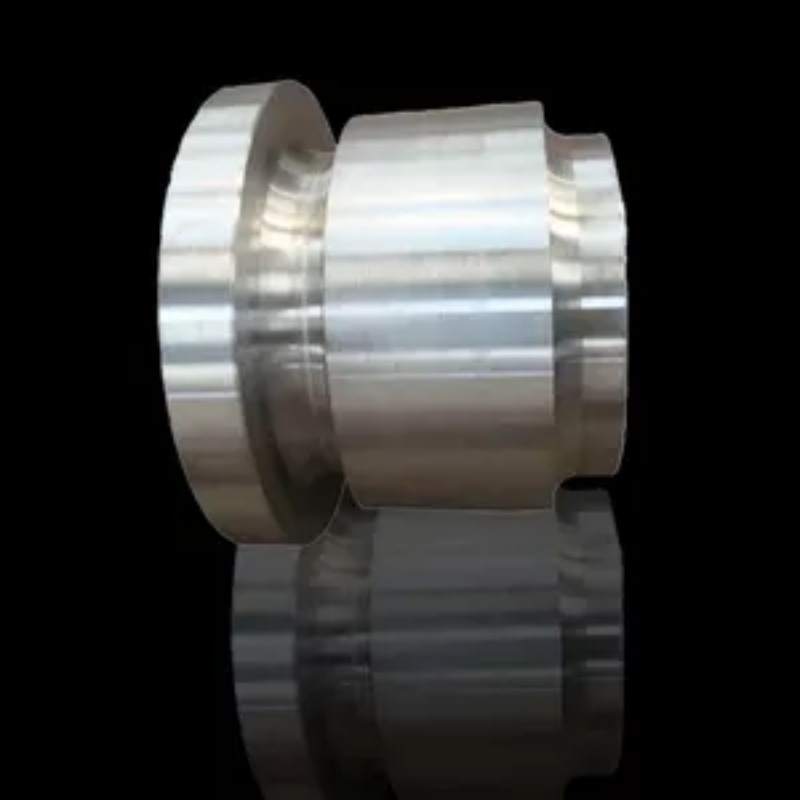

Slewing Ring

Slewing Bearing Application

Slewing bearings are generally composed of an inner ring and an outer ring, and also have a split structure of the inner ring or the outer ring. The inner ring or the outer ring can be machined with teeth at the same time and have mounting holes.

This makes the connection between adjacent components easier and faster. Through the joint action of the bearing raceway and the rolling element protection frame or isolation block assembly, slewing bearings can bear unidirectional load, bidirectional load, overturning moment, and combined load in any direction.

According to the form of the rolling element arrangement, slewing bearings can be generally divided into four-point contact ball slewing bearing, crossed roller slewing bearing, three-row roller slewing bearing, and so on. As a slewing bearing supplier, we will devote ourselves to satisfying customers' demands. The followings are the slewing bearing for sale.

Four-point Contact Ball Slewing Ring

Four-point contact ball bearings are radial single row angular contact ball bearings with raceways that are designed to support two-directional axial loading.

Cross Roller Slewing Ring

Cross-roller type slewing bearings, their rollers are arranged at 90° to each other at intervals between the inner ring and the outer ring. They can simultaneously bear loads from all directions (such as axial, radial, overturning moment, etc.). Because the rollers are in line contact with the track surface, the elastic deformation of the bearing under heavy load is correspondingly small and the rigidity is high. At the same time, it has mounting holes and sealing accessories or is equipped with teeth on the inner ring or outer ring to simplify the installation structure.

Three-row Roller Slewing Ring

The three-row cylindrical roller combined slewing bearing is mainly composed of an inner ring, an outer ring, three rows of rollers (two sets of axial and one set of radial rollers), a cage (spacer block), and has the characteristics of high load carrying capacity and good rigidity. At the same time, it has mounting holes and sealing accessories or is equipped with teeth on the inner ring or outer ring to simplify the installation structure.

The Working Principle of Slewing Ring

The working principle of the slewing ring is very simple: the way of moving the object is from sliding to rolling, reducing frictional resistance.

Specifically, the slewing ring mainly relies on lubrication and friction to achieve the effect of operation. Internally, it relies on the mutual friction between the ball and the steel ring to achieve the purpose of operation. Externally, it also relies on the friction between the slewing ring(the own or later added gear) and other components(drive gears, etc.) to start the operation and rub against each other, thereby driving the object to operate. Since it is mostly used to carry heavier large objects, its centripetal force is very high, which is also determined by its working principle, so it also needs a steel material that can ensure quality in terms of materials.

Of course, it is far from enough only with friction. Although it relies on friction to operate, lubrication is also essential. Just like the chain of a bicycle, if it is used for a long time and the friction is too large, it will also affect the use of parts. Therefore, after using this kind of bearing for a period of time, it is necessary to maintain it in time. Brush some lubricating oil or grease (on the external friction surface) and regularly lubricate the inside of the raceway to ensure that it can work well in a more suitable environment.

The Daily Maintenance of Slewing Ring

- In the case of bad working conditions, it is necessary to shorten the time interval for filling lubricating grease.

A specialized solutions provider of bearing technology, THB BearingsCo.Ltd (Shanghai) is one of the most professional Chinese bearing manufacturers and an industrial technical services company that offers customers a simple and convenient source for bearing products, technical services and solutions.

在线联系供应商

Other supplier products

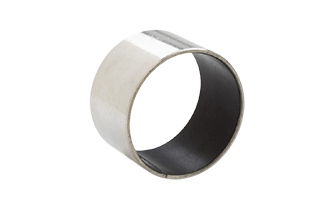

| Self-lubricating Bushing Bearings | Various bushings could be made with different materials. By different materials and structures, bushings could be divided into: solid bronze cylind... | |

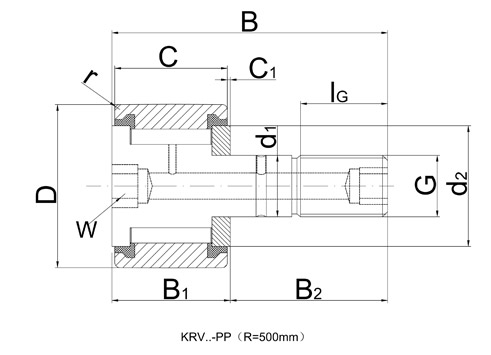

| KRV 26 PP/ CF 10-1 VBUUR Cam Follower | Specifications ofKRV 26 PP/ CF 10-1 VBUURCam Follower Designation KRV26PP CF10-1VBUUR (Mass)m... | |

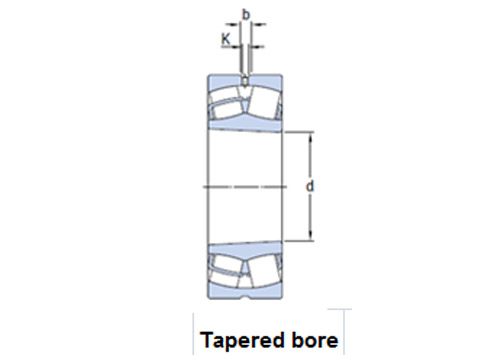

| Double Row Tapered Roller Bearing | Features of Double Row Tapered China VRoller Bearing High carrying capacity Continuous rotating Bearing radial and Bi-directio... | |

| Thrust Ball Bearing | They can only carry axial loads and cannot carry any radial loads. The shaft rings, seat rings and ball cages are separable and interchangeable. Be... | |

| 23168 CCK/W33 Spherical Roller Bearings | Specifications of 23168 CCKW33Spherical Roller Bearings Designations (Bearing with tapered bore) 23168CCK/W33 ... |

Same products

| Drum Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Drum Forging Drum Forging Brand origin: Runchi shandong Processing ability: turning, milling, pla... | |

| Wheel Hub Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Wheel Hub Forging Wheel Hub Forging Main features: [Manufacturing Standards] Strictly produce for... | |

| Nozzle Forging Nozzle | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Nozzle Forging Nozzle Forging Brand origin: Runchi shandong Processing ability: turning, milling,... | |

| Marine Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Marine Forging Marine ForgingMain features: [Manufacturing Standards] Strictly produce custom f... | |

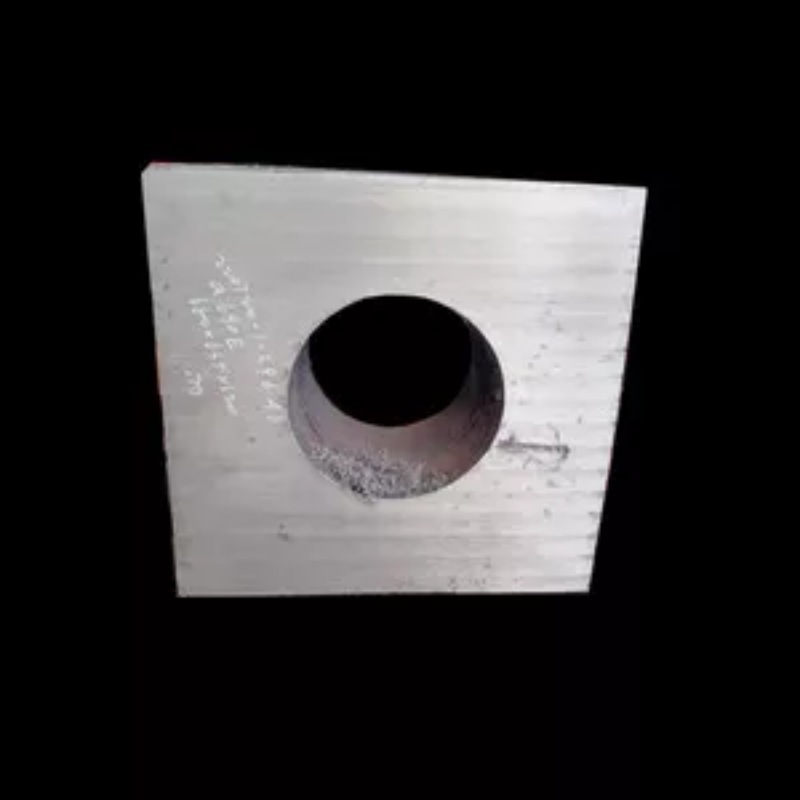

| Bearing Housing | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Bearing Housing Product Name: Bearing housingBrand origin: Runchi shandong Processing ability: ... |