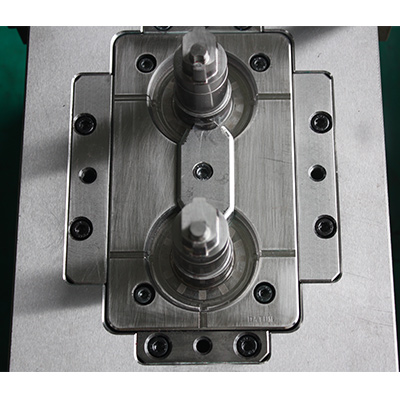

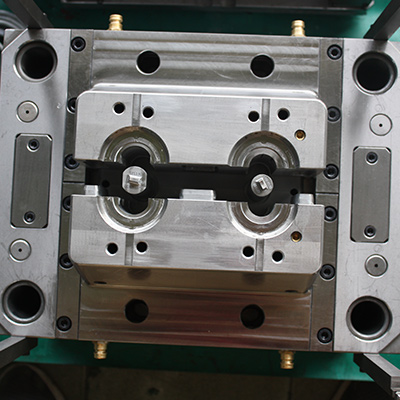

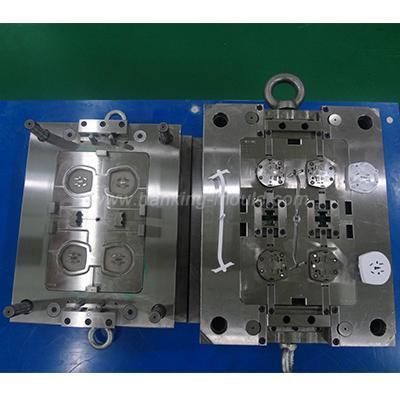

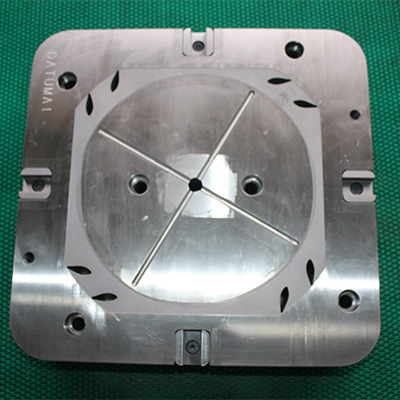

Precision Mould

How to build a plastic precision mould?

We have been manufacturing plastic precision moulds and componentsfor more than ten years. With our expertise and experience, we provide valuable mold opening suggestions to our customers according to their specific needs, thus helping customers save manpower and resources.

Plastic precision mould partsare normally required to be short mold cycle time and long life cycle, a good toolmaker should find the best mould solution combine the specific needs of customers, the mould must be easy handling and maintenance.

In order to ensure the smooth progress of the high precision mould project, detailed mould design analysis(DFM) must be done, and if necessary, mold flow analysis is required.

Before starting the processing, we need to communicate with the clients repeatedly, fully understand the needs of the customers, design the molds that meet the production requirements. DFM, mold design must be confirmed by customers before starting to manufacture the moulds.

Stable employees are also very important. We have a comfortable working environment: central air conditioning, dehumidification system, exhaust system and epoxy floor. Our employees and technicians have been working here for many years and this is an important factor in ensuring quality stability.

High Precision mould trial: With a special mold trial injection molding machine, qualified mold trial operator to ensure professional and on-time sampling service for customers.

In HanKing Mould, we have a complete set of high-precision measurement equipment, capable of providing full dimension FAI measurement reports.

Weekly work schedules, mould pictures, and test reports will be sent to the customers.

With reliable quality, on-time delivery and reasonable price, not only provide professional one-stop service from plastic precision mould development but also flexible service to individual molds or small batch plastic parts production. Whether the order is big or low volume, HanKing will make the best, all customers are VIP.

Hanking Mould, as an excellent precision mould supplier china, offers a wide range of precision mould for you to choose from.

在线联系供应商

Other supplier products

| Family Mould | What is the family mold? A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to prod... | |

| Gear Mold | Custom Plastic Gear Injection Mold Making, with many different dimensions and material, 2 cavities or 4 cavities customized plastic gear mold. HanK... | |

| Adapter Charger Housing Mold 496-1 | Mould Name: Adapter Charger Housing Mould Part Material: PC Product Size: 58.3*57.9*8.6mm Product Description: Adapter Charger Housing UK Mould... | |

| Industrial Mould | Industrial mould is not a mold technology process, but a type of mold that is distinguished from the purpose of use. Generally speaking, product... | |

| Insert Molding Technologies for Automotive Industry | Insert Molding Technologiesfor Automotive Industry Mould Type: Automotive Sensor Plastic Injection Mould Production Material: Nylon PA66 No ... |

Same products

| Galvanized Fishtail Terminal End for Highway Guardrail | 卖方: Wuhan Dachu Traffic Facilities Co., Ltd | Galvanized Road Fence Highway Guardrail Crash Barrier Terminal Endare the specially designed end ... | |

| COMMUNICATIONS PARTS | 卖方: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are radar system componentsin radar systems, where accuracy, reliability, an... | |

| POM CNC TURNING PARTS | 卖方: ShenZhen Haohaichang Industrial Co.,Ltd | CNC POMturning parts are precision components made from polyoxymethylene (POM) using computer num... | |

| Nut | 卖方: ShenZhen Haohaichang Industrial Co.,Ltd | Nuts are essential hardware components that work in tandem with bolts, screws, or other threaded ... | |

| HEATINGS/APPLIANCES PARTS | 卖方: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are essential components in heating and appliance systems, contributing to t... |