Cylindrical Roller Bearing

Compared with ball bearings, cylindrical roller bearings have higher radial load capacity. The design of cylindrical rolling elements also allows such bearings to accept relatively faster speeds than other forms of roller bearings.

Cylindrical roller bearings produced by THB Bearings, a cylindrical roller bearing types supplier owning its own cylinder roller bearing factory, have many designs, series, and sizes. The main design difference between the cylindrical roller bearing types is as follows.

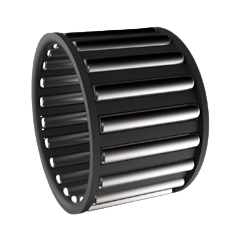

-The number of roller columns (one, two or four)

-The type of cages (with, without or with special design).

As one of the most professional and experienced cylindrical roller bearing suppliers&cylindrical roller bearing manufacturers in China, THB Bearings has its own cylinder roller bearing factory to ensure the quality of our products. So far, we have single-row cylinder roller bearings, double-row cylinder roller bearings, and face-point cylinder roller bearings for sale. Click and learn more info about cylinder roller bearings.

Single Row Cylindrial Roller Bearing

Single-row cylindrical roll bearings are usually only subjected to radial force. Compared with ball bearings of the same size, its radial bearing capacity is increased by 1.5-3 times, with good rigidity and impact resistance. Single row cylindrical roller bearings with unidirectional or bidirectional axial force structures can also be chosen to meet your needs.

Double Row Cylindrical Roller Bearing

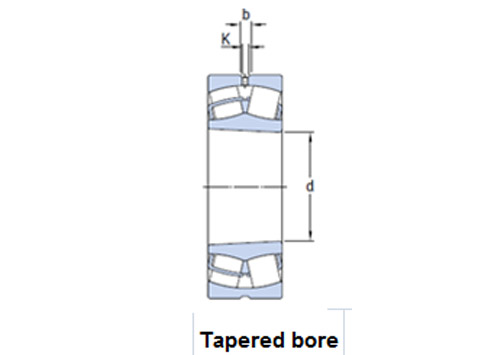

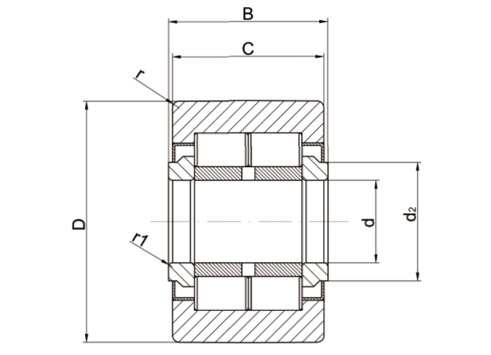

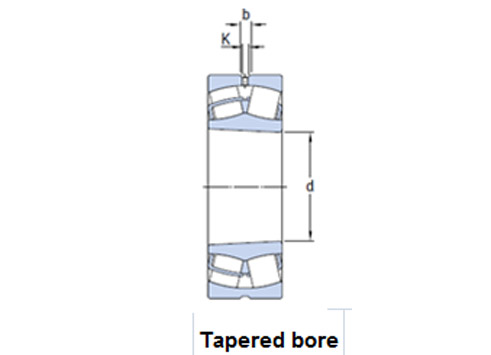

Double row cylindrical roller bearings have two structures: cylindrical bore and tapered bore. Double row cylindrical roller bearings have the advantages of compact structure, high rigidity, heavy bearing capacity.

Four-point Cylindrical Roller Bearing

Four-row cylindrical roller bearings are usually separated type, with heavy load capacity, mainly bear radial load, and are widely used in automobile, rolling mill, mining, metallurgy, plastic machinery and other industries.

Cylindrical Bearing Applications

Cylindrical roller bearings are suitable for rigid double-supported short shafts, shafts that cause axial displacement due to thermal elongation, and machine parts that need to be separated for installation and disassembly. Different types of cylindrical roller bearings created by THB Bearings, a professional cylinder roller bearing manufacturer, can meet various demands from customers all over the world. Cylindrical roller bearings are mainly applied in the following industries: large and medium-sized electric motors, rolling stock, machine tool spindles, internal combustion engines, generators, gas turbines, gearboxes, steel rolling mills, and vibrating screens, lifting and transportation machinery. If you have a need for cylindrical roller bearings, welcome to contact us. THB Bearings is your reliable cylindrical roller bearing types supplier.

Cylindrical Roller Bearing Types

THB Bearings is a professional cylindrical roller bearing types supplier with its own cylinder roller bearing factory.

We can produce different types of cylindrical rollerbearings according to customers' needs. Cylindrical rollers and raceways are linear contact bearings. With huge load capacity, cylindrical roller bearing mainly bears radial load. The friction between the rolling element and the retaining edge of the ring is small, which is suitable for high-speed rotation. According to whether the ring has ribs, it can be divided into single row cylindrical roller bearings such as NU, NJ, NUP, N, NF, and double row cylindrical roller bearings such as NNU and NN. Cylindrical roller bearing has a separable structure with inner ring and outer ring.

Cylindrical roller bearings without ribs on the inner ring or outer ring, the inner ring and outer ring can move relative to the axial direction, so it can be used as a free end bearing. Cylindrical roller bearings with double ribs on one side of the inner ring and outer ring and a single rib on the other side of the ring, can bear a certain degree of axial load in one direction. Generally, stamping steel cages or solid cages made of copper alloy cars are used.

Cylindrical roller bearings are separable bearings, which are very convenient for installation and disassembly. Cylindrical roller bearings can withstand larger radial loads and are suitable for use in high-speed running situations.

This type of bearing allows a very small angular error (inclination) between the axis of the inner ring and the axis of the outer ring, only 2'~4'. Therefore, the machining accuracy of the shaft and the bearing seat is relatively high. Otherwise, uneven load or stress concentration is likely to occur in the contact part of the raceway. But after correcting the roller or raceway contact bus bar, the occurrence of stress concentration can be reduced.

Cylindrical roller bearings can be divided into single-row, double-row and multi-row cylindrical roller bearings according to the number of rows of rolling elements. Bearings of different structures are also shown in the design of the position of the ribs. Among them, the commonly used cylindrical roller bearings have the following forms.

Cylindrical Roller Bearing Features

Roller and raceway are in linear contact or curved contact after modification, with large radial bearing capacity, suitable for bearing heavy loads and impact loads.

The friction coefficient is small, suitable for high speed, and the limit speed is close to the deep groove ball bearing.

The N type and NU type can move axially, can adapt to the change of the relative position between the shaft and the housing caused by thermal expansion or installation error, and can be used as a free end support.

The processing requirements for the shaft or the seat hole are high, and the relative deflection of the outer ring axis after the cylindrical roller bearing is installed must be strictly controlled to avoid contact stress concentration.

The inner ring or outer ring can be separated for easy installation and disassembly.

Cylindrical Roller Bearing VS Deep Groove Ball Bearing

The main difference between the two types of bearings lies in rolling elements, one is spherical rolling element, the other is cylindrical rolling element. It is precisely because the following differences between them have occurred.

Different bearing capacity: the contact surface of spherical rolling element and cylindrical rolling element is different. The spherical contact surface is a point, while the cylindrical contact surface is a line. Therefore, under the same size, the radial bearing capacity of cylindrical roller bearings is greater than that of deep groove ball bearings.

Different speeds: Because the contact surfaces of the rolling elements of the two bearings are different, their speeds are also different. The larger the contact surface is, the slower the relative speed is. Therefore, deep groove ball bearings with spherical rolling elements have an advantage in speed.

The noise is different: When the speed of the bearing of the same size is the same, the noise of the cylindrical roller bearing is greater than that of the deep groove ball bearing. This is also because the friction caused by the different contact surfaces of the rolling elements of the two bearings is different. The greater the friction surface, the greater the noise.

The difference between them is due to their different rolling elements. This also confirms one thing: every component in the bearing is an important part of its overall structure. Bearing products are composed of different structures and different components have different characteristics.

For more informationabout cylindrical roller bearing price, please feel free to contact us!

There are many chinese bearing manufacturers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| 22217 EK Spherical Roller Bearings | Specifications of 22217 EKBearing Designations (Bearing with tapered bore) 22217EK Principal dimensions (mm) d 85 ... | |

| KR 35 PP | A specialized solutions provider of bearing technology, THB Bearings Co.Ltd (Shanghai) is an industrial technical services company that offers cust... | |

| Cross Cylindrical Roller Bearing | Crossed cylindrical roller bearingsselection must confirm below requirement. Rotation by inner ring or outer ring and the rotation speed Di... | |

| NUTR 15 Support Roller | Specifications of NUTR 15Support Roller Item NUTR15 (Mass) m≈g 99 Dimensions D 35 d... | |

| 22216 EK Spherical Roller Bearings | Specifications of 22216 EKBearings Designations (Bearing with tapered bore) 22216EK Principal dimensions (mm) d 80... |

Same products

| Flexible Sports Tape | 卖方: manager | Flexible Sports Tape SCICO CARE specializes in manufacturing high-quality flexible sports ta... | |

| F607 Bearing | 卖方: Guangzhou Rimao | F607 Bearing are a common type of miniature deep groove ball bearings, which are widely used... | |

| Tapered Roller Bearing | 卖方: Guangzhou Rimao | Tapered Roller Bearing Tapered Roller Bearings – Precision Solutions for Heavy-Duty... | |

| Cable Roller | 卖方: 00000 | Cable Roller Cable Roller Your One-Stop Solution for Hebei Long Zhuo Trade Co., Ltd. is... | |

| Cable Laying Tools | 卖方: 00000 | Cable Laying Tools Cable Laying Tools Look for manufacturers that specialize in cable lay... |