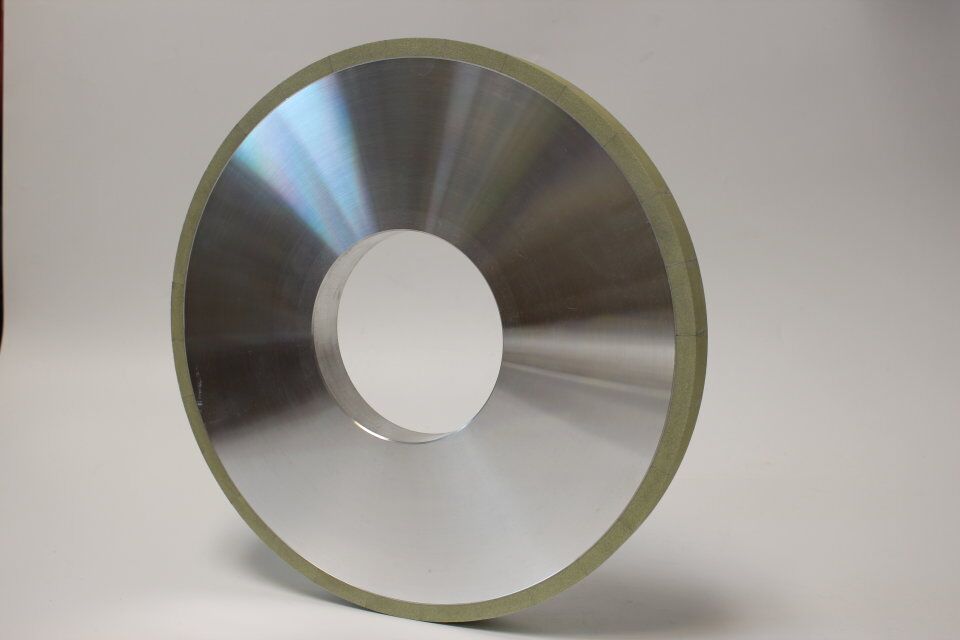

Universal Crankshaft Grinding Wheel

Features of universal crankshaft grinding wheel:

Crankshaft grinding wheel can be classified into parallel shape, single groove shape, double groove shape, multi-interface wheel and wheel with heat radiating groove. Grinding products are characterized with superior performance, good self-sharpening, good balancing performance.

In the process of grinding, it can maintain the R angle precision and roughness of crankshaft neck. We can design and develop crankshaft grinding wheel according to the requirements of customers.

Advantages of universal crankshaft grinding wheel:

It is ofdurable sharpness, lower grinding temperature and vibration of the work piece, energy-saving and minimum deformation layer in the metal processing. It can be achieved that the work piece is flat and straight accurately, which is helpful to provide customers with better quality. Tolerance of the work piece is easier to be achieved and effectively maintained.

It is of excellent self-sharpening,which can increase the feed rate and speed, and improve the efficiency. In addition, it can prolongthe dressing interval, reduce the dressing times and make the life of grinding wheel longer. The life is five times longer than that of the general grinding wheel.

It is superior for steel and alloy steel processing.

Application of universal crankshaft grinding wheel:

The crankshaft grinding wheel is mainly used for grinding crankshaft for engines of cars, trucks, motorcycles, aircraft, and large-scale marine diesel engines that is made of the high-strength wear-resistant alloy steel, forged steel, cast steel or ductile iron.

Size of universal crankshaft grinding wheel:

|

Model Name |

D(mm) |

T(mm) |

H(mm) |

Application |

|

Crashaft Grinding Wheel |

650 |

33-40 |

305 |

Grinding crankshaft for engines of cars, trucks, motorcycles, aircraft,etc |

|

750 |

20-75 |

305 |

||

|

900 |

20-100 |

305 |

||

|

1065 |

22-60 |

|||

|

1200 |

25-100 |

|||

|

According to customers’ requirements |

||||

在线联系供应商

Other supplier products

| Metal Bond Cutting Disc, Cutting Wheels | Metal Bond Cutting Disc, Cutting Wheels Metal Bond Cutting Discs Are Mainly Used For Grooving And Cutting With High Accuracy And Slight Cutting ... | |

| Reasaw BANDSAW BLADES | diamond band saw blade with segment used for cutting marble /granite Advantage Using high quality grit electroplated to the blade edge - NIABRA... | |

| vitrified diamond grinding wheel | Cylindrical vitrified diamond grinding wheel is used for PCD tools grinding with large cylindrical grinding machines.The PCD tools in automotive in... | |

| The Used PDC Cutter | PCD Polycrystalline Diamond NaturalDiamondProcessingIndustry Type: cylindrical, Square, Flake And so on Lead Time: 10 ~ 12 Days Payme... | |

| PDC Bits, PCD Bits | CVD Diamond Tools PCD & PCBN Tools Processing Industry Application: Dressing Tools Payment Terms: T/T, Western Union, MoneyGram, PayPal... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |