Family Mould

HanKing Mould Enginering Ltd. started the business in the year of 1996 as one of the chinese plastic injection molding companiesin the line of mold making and injection molding in Longgang, Shenzhen, China. With continuous developments and progresses, we have become a professional Chinese plastic injection tooling company, offering custom plastic injection molding service, plastic moldingmanufacturing and other mould making services.

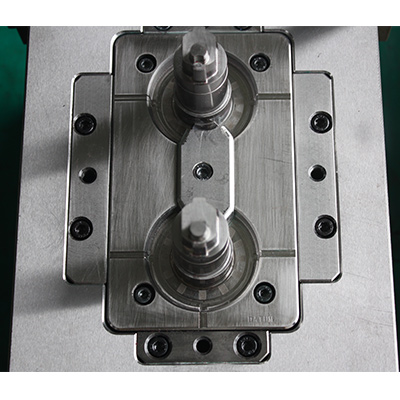

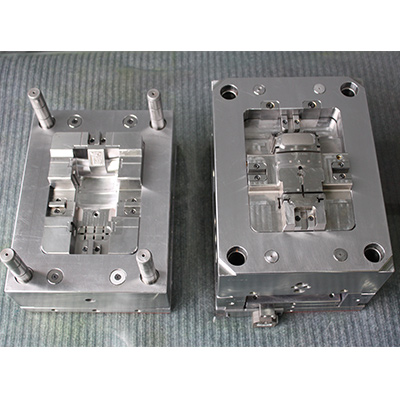

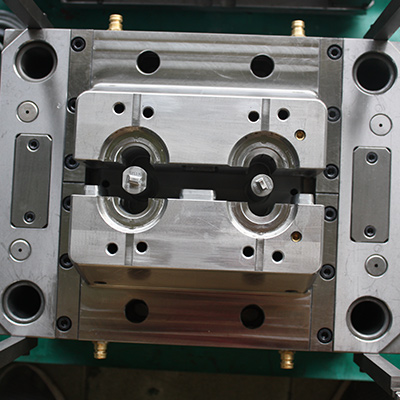

Family Injection Mold

Mould Name: 1+1 Family MouldPart Material: PA6 GF30Product Size: Product Description: Scharnier right & Left Mould Cavity: 1 +1 CavityMould Size: 350*440*498MMSuitable Injection Machine:Mould Cavity Steel: 8...

Family Mold Tool

Mould Name: 1+1 Family MouldPart Material: PA6 GF30Product Size: Product Description: Scharnier right & Left Mould Cavity: 1 +1 CavityMould Size: 350*440*498MMSuitable Injection Machine:Mould Cavity Steel: 8...

Family Mold

Mould Name: 1+1 Family MouldPart Material: PA6 GF30Product Size: Product Description: Scharnier right & Left Mould Cavity: 1 +1 CavityMould Size: 350*440*498MMSuitable Injection Machine:Mould Cavity Steel: 8...

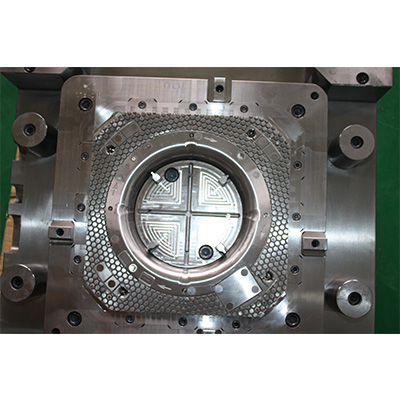

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low industrial mouldmanufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

The plastic parts produced by the multi-cavity mold or family mouldhave low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the family mold injection moldingmachine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold help to molding different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

在线联系供应商

Other supplier products

| Gear Mold | Custom Plastic Gear Injection Mold Making, with many different dimensions and material, 2 cavities or 4 cavities customized plastic gear mold. HanK... | |

| Plastic Precision Car Parts | Mould Type: Plastic Precision Car PartsMould Production Material: PC, PP, PA6, PA66, PE, ABS, HDPE, TPE, TPU, PET, PPS, POM, PBT, PMMA, PPS, SAN... | |

| Plastic Mould for Air Guiding Fan | With continuous developments and progresses, we have become theprofessional china plastic injection mould manufacturers, offering custom plastic in... | |

| Mold Trial | Plastic Mould Trialof Hankingtec In hanking mould’s trial shop, HanKing Mould Enginering Ltd.has7 injection molding machines with a clamping... | |

| Plastic Injection Moulding Die Makers | Plastic Injection Moulding Die Makers Plastic mould die makerin China Focus on all kinds of mould development, various plastic mold manufactu... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |