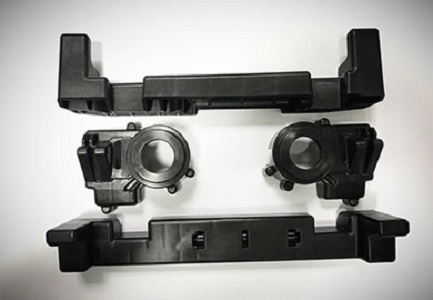

Automotive Part

As the foundation of the automotive industry, injection moulding automotive partsare necessary factors to support the sustainable and healthy development of automotive mold manufacturers.

In particular, the current independent development and innovation in the automotive parts mold industry that is being carried out vigorously and in full swing require a strong component system in automotive plastic injection molding companies. Vehicle independent brands and technological innovation require automotive injection mold parts and components as the foundation, and independent innovation of parts and components has a strong driving force for the development of the vehicle injection molding automotive parts industry.

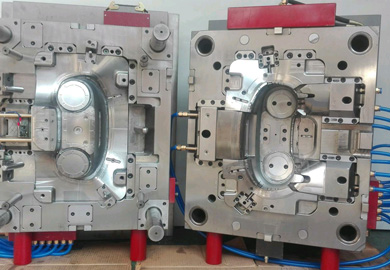

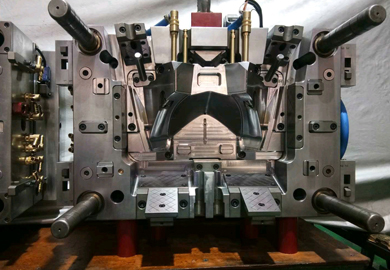

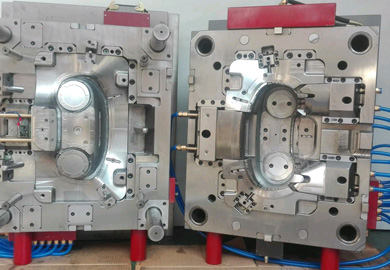

Features of Automotive Injection Mold

Here are three major features of using automotive injection molding for manufacturing injection moulding car parts.

Detailed Features

The automotive plastic injection molding is subjected to extremely high pressure. Therefore, the plastic is pressed harder against the automotive parts mold. This complex and intricate shapes of plastic injection molding automotive parts can easily be designed.

High Efficiency

Once the automotive parts molds have been manufactured to the customer’s specifications, it is very quick to the actual automotive precision plastic injection moulding. The high production output rate makes plastic injection molding automotive parts more cost-effective and efficient.

Enhanced Strength

In automotive plastic injection molding, it is possible to use fillers in the injection molds. This filler reduces the density of the plastic which will enhance strength.

How does Automotive Injection Mold Work?

Automotive injection mold is to first add plastic to the mold, and then the automotive parts mold is continuously rotated along two vertical axes and heated. Under the action of gravity and thermal energy, the plastic in the automotive parts mold is uniformly coated and melted, and adhered to the entire cavity of the mold. On the surface, it is formed into the required shape of injection molding automotive parts and is made by cooling and shaping.

The Specification of injection molding automotive parts

|

Part material |

ABS + PC |

|

Mould Cavity |

1 |

|

Mould steel |

|

|

Mould steel |

A, B, C, plate P20, others 1.1730 |

|

Tooling life |

100W |

|

Mould standard |

HASCO |

|

Exporting country |

Germany |

|

Leadtime |

5 weeks |

|

Customer satisfaction with mould quality |

95% |

|

FAI pass rate |

99% |

|

Customer satisfaction with project cooperation service |

98% |

As an automotive mold technology co ltd, we have types of injection molded partsfor sale, anything you need, contact us.

If you want to know more details of in mold technology, please visit our website.

在线联系供应商

Other supplier products

| Electronics Product Part | With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can... | |

| Mould Slide | The slider is a mold component that can slide in a certain angle perpendicular to or with the opening and closing direction during the opening and ... | |

| Mould Base | After years of development, mold base production industry has been quite mature. Mold manufacturers can purchase customized mold base according to ... | |

| Electronics Product Mould | Electronics Product Mould Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding pr... | |

| Product Development | Our company is not engaged in product development, but we are willing to assist customers to design product appearance and product structure in cas... |

Same products

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... | |

| Plastic Injection Mould For 2009 Audi A5 Front Bumper | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Our Advantage:1.We have developed about 1000 PCS bumper mould since we founded.2.Our company's mo... | |

| Double Color Mold For Car Head Lighting Two-Shot Mold | 卖方: Taizhou Toolsong Mould Co., Ltd. | Double Color Mold For Car Head Lighting Two-Shot Mold Double color lens mold for car head lighti... |