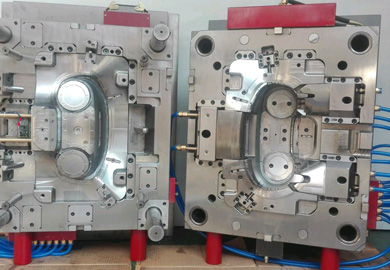

Home Appliance Mould

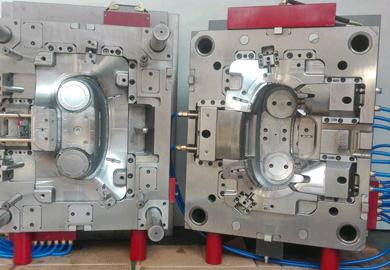

Household appliances mouldcombines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, household appliances are closely related to china home appliance mold.

As a leading home appliance plastic injection moulding manufacturer, GM-TECH makes sure all the products made by moulding meet the demanding requirements of our customers. We are devoted ourselves improving the service and home appliance mould quality continuously.

Features of Home Appliance Mould

With the development of the home appliance industry, applications of home appliance mold are popular in the injection process such as fan mould, computer mould, air conditioner mould, refrigerator mould, and so on. So why are there wide applications of home appliance mold?

High precision and long service life

The home appliance mould adopts an inlaid or fully assembled structure, improving the high processing accuracy of plastic injection moulding parts.

Off-site design and off-site processing

The plastic home appliance mold process requires to meet customer needs and provide mass production by off-site design and off-site processing.

Short processing time

For injection home appliance mould parts, most of them are matched with other injection molding types, which can save processing time.

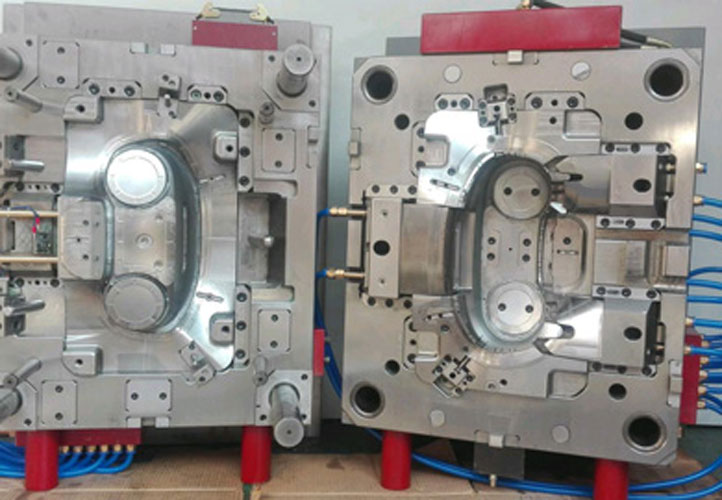

The Specification of Home Appliance Mould

|

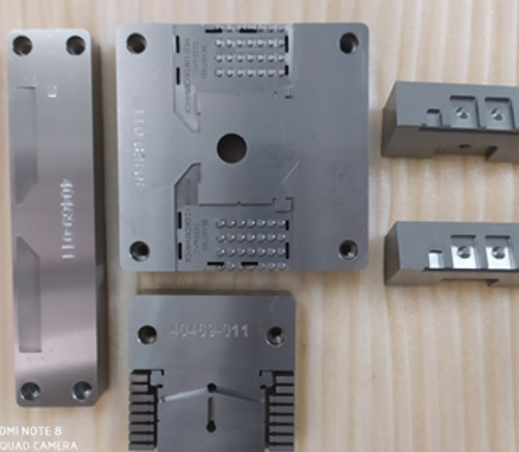

High precision mould |

|

|

Part material |

PBT |

|

Cavity |

1L + 1R |

|

Mould accuracy |

+ / - 0.02 |

|

Mould steel |

|

|

Mouldbase steel |

|

|

Mould life |

100W |

|

Mould standard |

HASCO |

|

Mould structure |

4 slides |

|

Exporting country |

Russia |

|

Leadtime |

6 weeks |

|

Mould quality customer satisfaction |

96% |

|

FAI pass rate |

98% |

|

Project cooperation service customer satisfaction |

99% |

How does Home Appliance Mould Work?

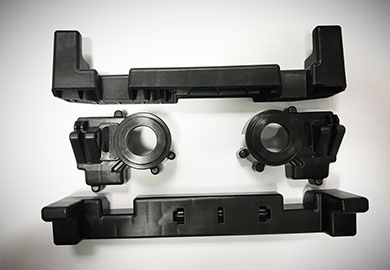

Before we explore the working principle of home appliance mould, the first stage is to make a mould. Then the material is fed into a heated barrel and mixed using a helical-shaped screw.

Heating bands make the material melt. Next, the mixed materials, generally metal and plastic, are fed to the cavity of the home appliance mould to keep cooling. Finally, the shape of the home appliance mould is formed as we designed.

More details of mold technology, please visit our website.

在线联系供应商

Other supplier products

| CNC Components | Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. If we want to ch... | |

| Electronics Product Part | Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injectio... | |

| CNC Prototype CNC | GM-TECH, plastic injection molding factory,has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Mould Component | Plastic injection mold componentsare also a part of the mould. As one of plastic injection molding companies, GM-TECH not only produces precision m... | |

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |