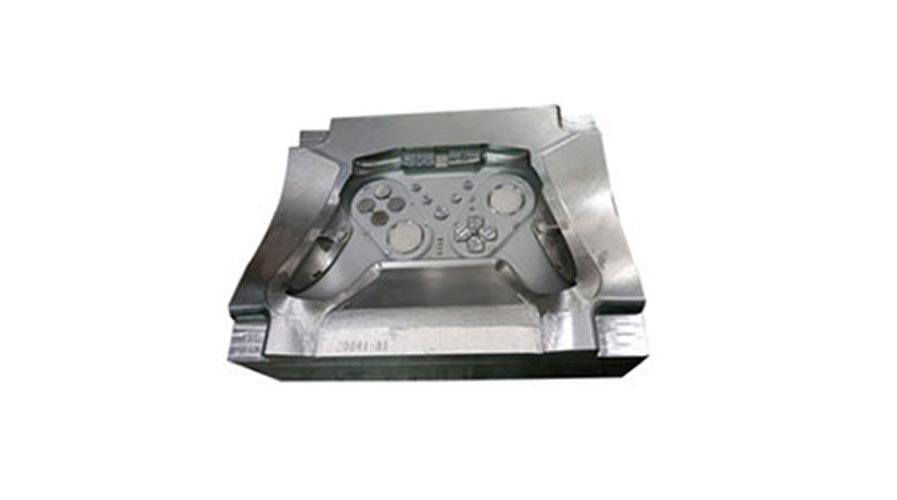

Game Controller Mold

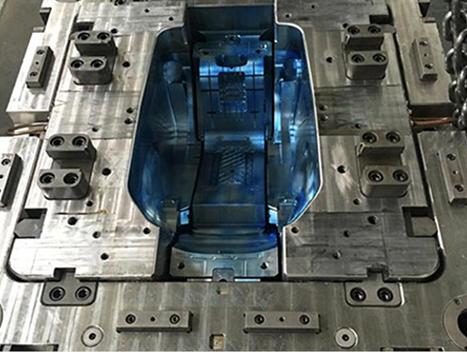

To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time will be saved and the production efficiency increased. Green Vitality concerns a lot on mold cooling system and production stability. Our aim is to make customer run molds as less as possible for mold repair work, the best condition is free of repair work during mass production.

High-quality Game Controller Mould

To produce a high qualifed Gamepad mold, we need to work hard on mold design and analyze injection, ejection and cooling system, so that the gamepad is without flash, sinkmark, deformation and easy demoulding. These are very important factors when making gamepad mold and injection the parts. Some gamepad mold is textured on the surface, while some are glossy. Green Vitality has rich experience in making both textured molds and polished molds. Except mold building, we also provide injection molding, painting, printing, electroplating, ultrasonic welding, assembly service.

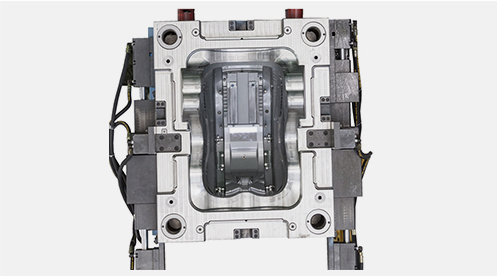

Basic Information for Game Controller Molds

|

Description |

Gamepad Plastic Injection Mold |

|

Plastic material |

ABS |

|

Part dimension(mm) |

180*140*70mm |

|

Mould dimension(mm) |

400*550*460*mm |

|

Mould weight (KG) |

730KG |

|

Mould cavity&core steel |

718 |

|

Nos of Cavity |

2 |

|

Manufacture time (day) |

30 days |

|

Mould life |

≥500000 |

|

Molding cycle (S) |

The 30s |

|

Mold Characteristics |

Multiple cavities mold |

|

Slide and ejector pin structure |

Why Choose Us To Make Your Electronic Molds And Molding Parts?

Green Vitality offers a turnkey plastic molding solution from concept ideas to actual products. We make 3d printing, mold design, mold making, parts injection, surface treatment, and post-molding operation services.

State of art mold processing and parts testing equipment.

Professional engineers, technicians, workers, sales, and after-sales teams.

ISO9001:2015 quality control system and modern Japanese management

24hours a day, 7days a week, two shifts working to meet your output demands.

25years experience in plastic injection mold and molding field.

Our motto is Quality is First, Customer is First.

As a plastic mould supplier, we can offer kinds of plastic injection moldingpartsfor sale, anything you need, please contact us.

在线联系供应商

Other supplier products

| Auto Part Mold | With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by inje... | |

| Car Seat Mould for Kids | Child safety seats are seats specially designed to protect children from injury or death in a collision. The main structure of the child safety sea... | |

| Filter and Flow Limiting Apparatus | The family mold is used to produce injection parts for liquid filtration and flow monitoring and control systems. These accessories are custom... | |

| Game Controller Mold | Game Controller Molds To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, mach... | |

| Medical Plastic Injection Mold | Provide complete solutions from product design/mold manufacturing/injection mass production. Provide professional medical consumables and medica... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |