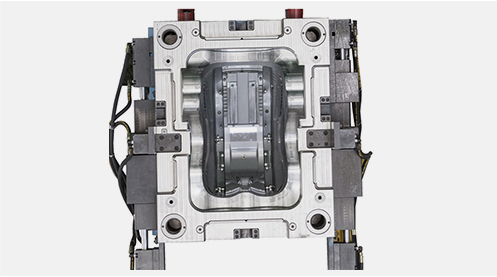

Plastic Connector Mould with Brass Molding Inserts

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an integrated products of both metal and plastic.

The connector is designed with brass insert, it is a good insulator with better strength, so it is applied for electronic and electrical power components, machinery and equipment installation.

High-quality brass inserts for injection molding

This mold is multi-cavities 1*2. The insert positioning block for the copper can be taken out and put in easily from the cavities. The brass insert was preheated to ensure a uniform temperature in the mold cavities.

Basic Information for Connector with Brass

Plastic Connector MouldSpecification

|

Description |

Connector with Brass |

|

Plastic material |

ABS |

|

Mould dimension(mm) |

300*300*410 mm |

|

Mould weight (T) |

350 kgs |

|

Mould cavity & core steel |

H13 |

|

Nos of Cavity |

1*2 |

|

Manufacture time (day) |

30 days |

|

Mould life |

≥50,0000 |

|

Molding cycle (S) |

35 S |

|

Cooling line connector type |

quick coupling |

|

Mold Characteristics |

insert positioning block |

Benefits of Plastic Connector Molded with Brass Insert

Plastic molding part with metal material insert provides you additional functions, you can obtain great advantages including:

It is of electric conduction with brass insert for electronic devices electrical equipment.

To design with screw thread section on the metal, it can be installed to devices and equipment very conveniently.

With metal insert, it enhances the strength of the plastic molding connector.

It is of electrical insulation and heat insulation for safety sake.

With low-level noise.

How To Design A Connector With Metal Insert

Select metal materials with a small coefficient of thermal expansion as inlay materials, such as brass, aluminum, aluminum alloy, etc.

The metal design shall not have sharp corners, and shall be properly rounded to improve the plastic strength. The surface of the insert should preferably be provided with exquisite rolling patterns or grooves to increase the friction.

The plastic thickness around the metal insert shall be sufficient. For example, the plastic thickness around the insert is "h", the outer diameter of the metal insert is "D", the plastic thickness for the aluminum insert should be h ≥ 0.8D, and the plastic thickness for the brass insert should be h ≥ 0.9D.

Green Vitality Industry is a professional injection molding factoryin various industries since 1993. We provide metal insert moulding, plastic insert moulding, brass molding inserts, metal insert molding, injection moldand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Car Seat Mould for Kids | Child safety seats are seats specially designed to protect children from injury or death in a collision. The main structure of the child safety sea... | |

| Medical Plastic Injection Mold | Provide complete solutions from product design/mold manufacturing/injection mass production. Provide professional medical consumables and medica... | |

| Home Appliance Mould | Home Appliance Mould GV Mold has rich experience in home appliance mold(such as television, refrigerators, fans, washing machines, air conditi... | |

| Plastic Food Container Mould | Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... | |

| Industrial Plastic Injection Mold | Plastic Mould Industry The industrial plastic injection moldis replacing metal products in many fields of industrial applications to meet the requ... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |