Plastic Food Container Mould

Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental protectionso, we have to choose proper plastic materials, such as food grade PP,PS,starch material,Plant fiber material etc., then food container mould should be signed with high polish, good injecting and cooling systems to make sure the boxes could be with good shap and finish.For enhancing the speed, normally we suggest to produce plastic container mouldon high speed injection machines.

High-quality Food Container Mould

As the wall thickness of the boxes is normally very thin, it's very important to design and make high-quality plastic food container mould. An efficient mold cooling system can shorten the injection cycle and save more processing costs and time. We pay great attention to the mold cooling system and mold production stability. Our goal is to ensure customers run as little mold repair work as possible and be able to perform mass production efficiently and stably.

Basic Information for Lunch Box Mold

|

Description |

Plastic meal box mold |

|

Plastic material |

PP |

|

Mould dimension(mm) |

1000*860*320 |

|

Mould weight (T) |

|

|

Mould cavity&core steel |

P20 |

|

Nos of Cavity |

1*4 |

|

Manufacture time (day) |

45 days |

|

Mould life |

≥500000 |

|

Molding cycle (S) |

30S |

|

Cooling line connector type |

DME NS350 SERIES quick coupling, |

|

Mold Characteristics |

excellent cooling system design |

|

Short cycle time |

Points of making plastic meal box mold

Designing about 2-3 different sizes of plastic meal boxes with the same lid could save the mold and production cost.

The thickness of the boxes is thin, so we need to design the mold with a good cooling system.

The materials of the boxes should be safe for hot food and meet environmental concerns.

To enhance production efficiency, you need to use a high-speed injection molding machine for production.

Using robots to pick up the parts during production can also enhance production efficiency.

Following our construction to install and use the mold, to make sure there's no any damage for the mold and less repair.

Want to know the details of custom plastic injection moldand plastic molded parts, contact us.

在线联系供应商

Other supplier products

| Mouse Mold | One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which co... | |

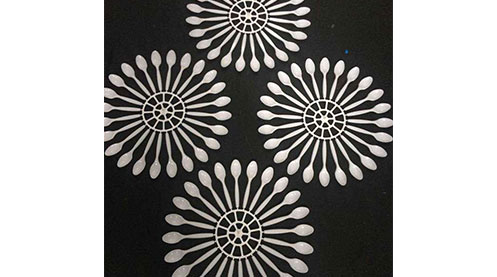

| Plastic Spoon Mould | lastic spoon mainly used for eating, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental protectionso, w... | |

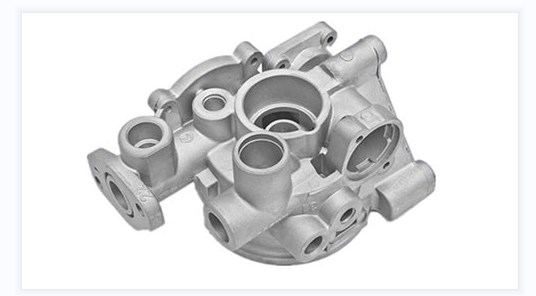

| Aluminum Die Casting Mold | Aluminum High Pressure Die Casting Mold When working at high or low temperatures, they also maintain good mechanical properties and have good co... | |

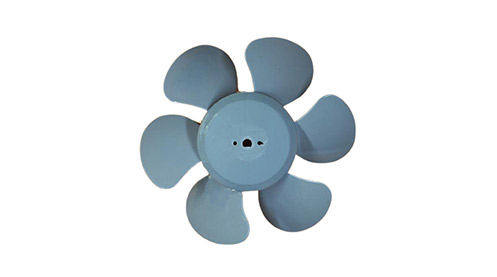

| Fan Mold | If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rot... | |

| Plastic Food Container Mould | Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |