Product Design & Development

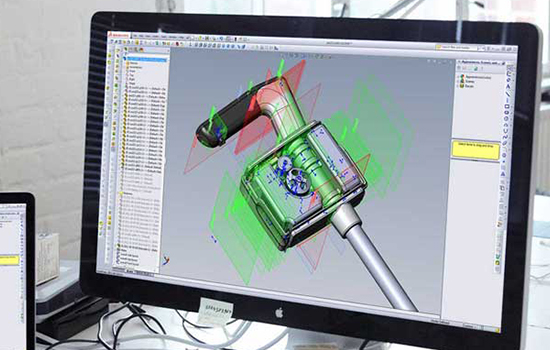

In addition to providing moulding die designsolutions, we can also provide customers with product design optimization solutions to save more cost and time during mold processing. With the continuous development of the company, our engineering department has been constantly optimizing the staffing. They have very rich experience enough to meet your various product design requirements. We can directly do product design or provide optimized solutions for your products, and then provide mold design solutions and moulding solutions.

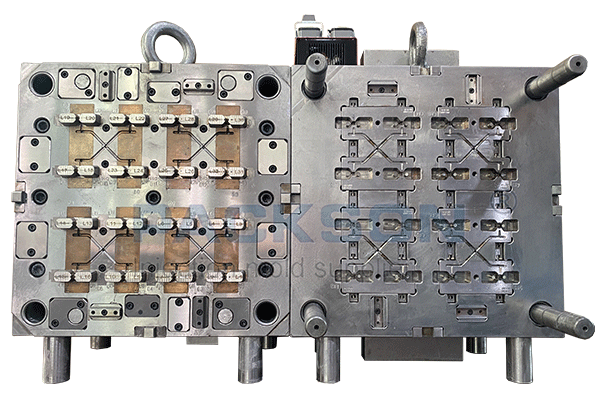

Advantage of Packson MoldDesign

As a professional mold design company, we also have very strict standards and process requirements for molding die design.

We will do our best to provide customers with the most cost-optimized mould tool designsolutions to help customers achieve cost savings and shorten production cycles. This is also a very good solution for us because it also saves us cost and time.

Through the following, you can understand our engineering standards.

Engineering

-Pro/ENGINNER(3D Modeling)

-Solid works(3D Modeling)

-AutoCAD(2D Modeling)

-Mold flow Mold Advisor (Plastic flow/deform simulation)-outsource

-Master CAM (CNC Programming)

-Unigraphics (CNC Programming)

-CNC Machining Centers

-CNC EDM’s (Electro-Discharge Machining)

-Wire-Cut Machines

There are many medical injection molding companies, but we are one of the best choices for you.

在线联系供应商

Other supplier products

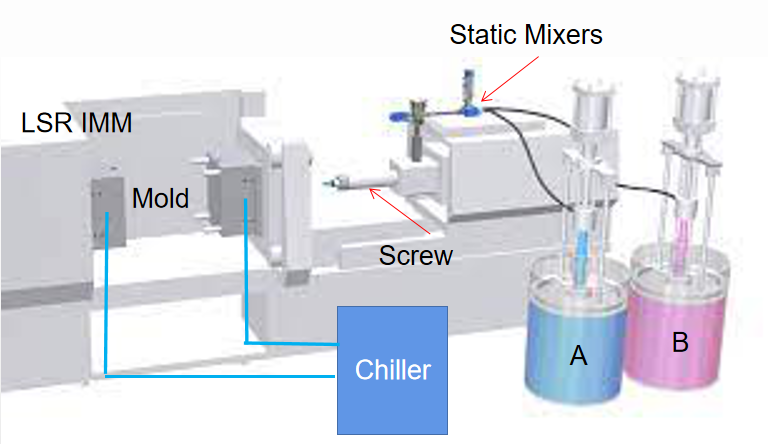

| Silicone Rubber Injection Molding | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability Silicone rubber injection m... | |

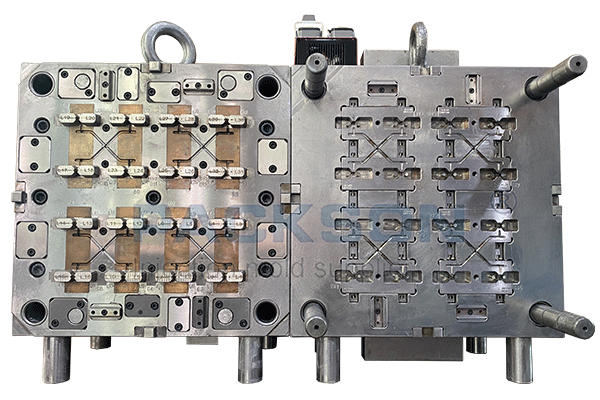

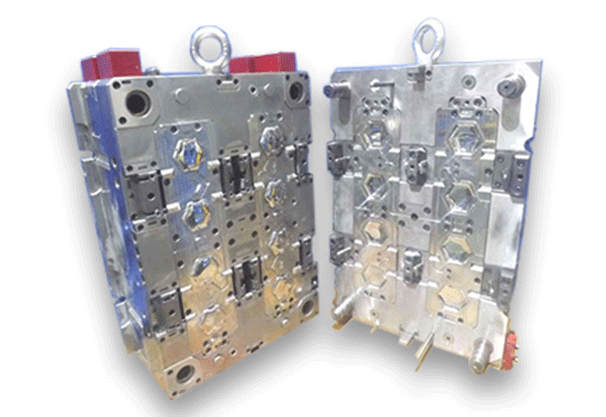

| Multi-cavities Injection Molding | Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold designis to produce m... | |

| Precision Injection Molding | Precision mold componentsis a process that requires high technique and the use of precision molds and precision machines. The process of precision ... | |

| Medical Plastic Parts | To be a qualified medical plastic components manufacturer, the most advanced technology and continuous compliance and certification are the pillars... | |

| Multi-cavities Injection Molding | Multi cavity mould is an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold design is to produce... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |