Medical Plastic Injection Molding

Packson - Medical Plastic Injection Molding Expert

Packson sets itself apart from other medical injection molding companiesthrough its distinguished ISO certification for medical injection molding services. Holding certifications for both ISO 13485:2018 and ISO 9001:2008, Packson guarantees the exceptional quality of its services.

Since 2008, Packson has been a trusted provider of Medical Plastic Injectionservices to esteemed healthcare and medical enterprises like BD and Wondfo. Our dedicated team of 30-40 highly skilled production operators works tirelessly in three shifts, 24 hours a day, to ensure seamless handling of your long-run medical plastic injection molding production. This unwavering commitment enables us to expedite the delivery of your medical plastic partsto the market promptly and efficiently.

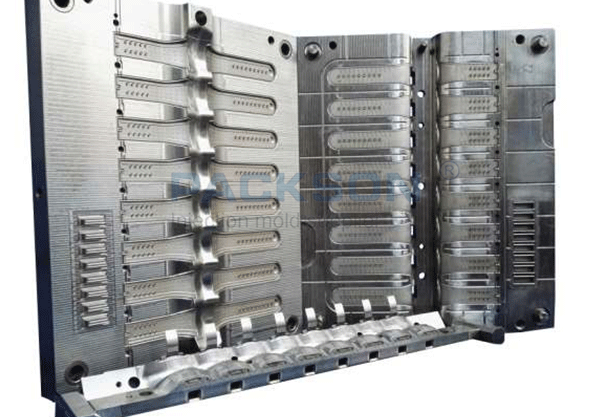

As a professional China-based medical device injection molding companies, Packson helps customers by providing optimized multi-cavities solutions for high-volume medical plastic moldingproduction. Packson's "weapons" include a comprehensive and automated assembly line equipped with mechanical arm part handling systems, sonic welding, heat staking, laser-engraving, plastic package sealing, and custom packaging capabilities.

With extensive experience in OEMs for medical contract manufacturing services, Packson is a trustworthy partner for those seeking reliable medical injection molding solutions.

Packson Clean Room Injection Molding

Packson's clean room manufacturing and assembly services encompass a comprehensive range of capabilities. These include:

ISO Class 8 Cleanroom Injection

Laser Welding

Bonding (UV and solvent)

Decorating

Flaring

Tipping

Packaging (pouch and tray)

Force testing (pull force, burst, and torque)

IQ/OQ/PQ validations

With our expertise in these areas, Packson is well-equipped to handle diverse medical device projects and deliver high-quality products that meet stringent industry standards.

Packson Medical Device Cleanroom Capabilities

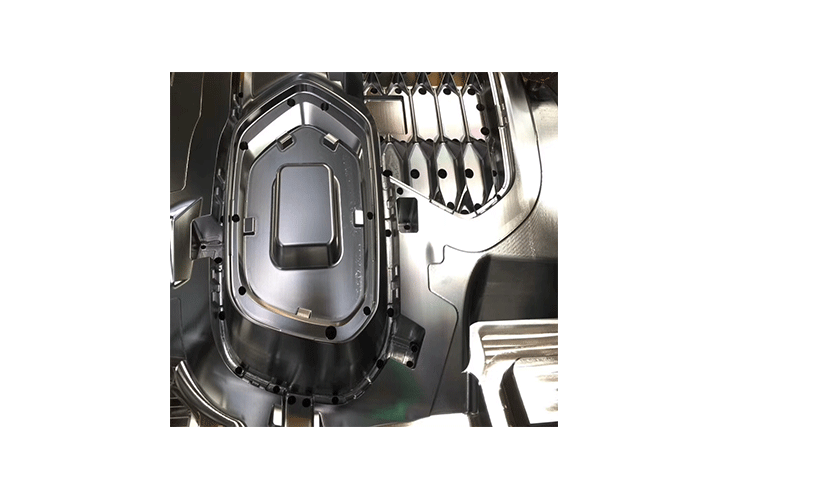

At Packson, we take great pride in our advanced medical device injection molding cleanroom, meticulously designed to meet the most stringent cleanliness requirements. Our cleanroom provides the ideal environment for producing medical devices of unparalleled quality, combining various materials with precision to cater to our customers' unique demands.

Our Commitment to Efficiency and Excellence: State-of-the-Art Equipment: Equipped with cutting-edge technology, our cleanroom houses the latest injection molding machinery to ensure precise and efficient production processes.

Skilled Engineers: Our team of highly skilled engineers brings their expertise to every project, reducing the risk of errors and streamlining the manufacturing process.

Time and Cost Savings: By leveraging our advanced technology and skilled workforce, we have significantly reduced project lead times and overall costs, translating into greater efficiency for our customers.

Meeting the Demands of the Medical Industry: As a leading medical plastic injection molding companies, we are dedicated to serving the needs of the medical industry. Our cleanroom facilitates the molding and assembly of medical devices, utilizing a wide array of materials, including medical-grade thermoplastics, to meet various healthcare and medical standards.

Focused on Precision and Scale: From small-batch productions to high-volume manufacturing, our cleanroom remains committed to creating precise medical components. Operating within ISO Class 7&8 cleanroom environments, we maintain the highest level of cleanliness and quality assurance.

Value-Added Services for Comprehensive Solutions: To provide a full spectrum of OEM medical device injection molding services, we offer a range of value-added services such as ultrasonic welding, printing, assembling, packaging, and sterilization. This comprehensive approach ensures that our customers receive end-to-end solutions tailored to their requirements.

If you are interested in our cutting-edge medical plastic injection molding cleanroom and wish to learn more, please don't hesitate to contact us today. Our team is ready to address any inquiries and collaborate with you to bring your medical device projects to fruition.

Expanded Packson Clean Room Medical Injection Molding Services

Packson Clean Room Injection Molding Process

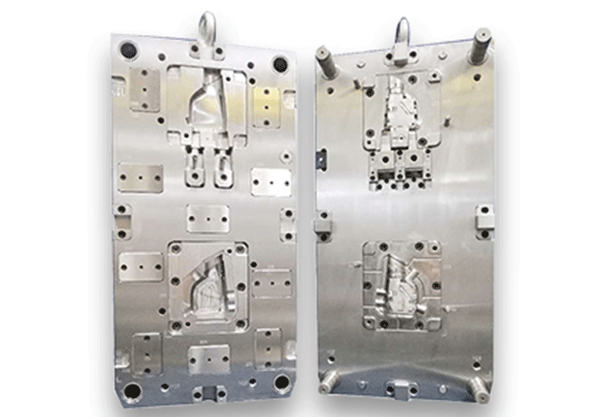

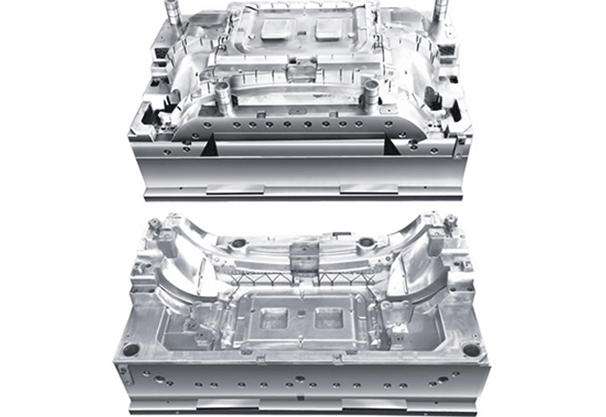

Our medical device injection molding parts are made by injection mold. The first step for making mold is to review the part design. Our medical device injection molding normally can reach 100,000 cycles even more if we use suitable steel material for the mold. Packson offers clean room injection molding service of a lifetime warranty for molds by mold maintaining. Here we have a professional engineering team that is dedicated to your injection molding production.

Process for Clean Room Injection Molding Production:

Quick response for mold and part quote

Analyzing part design and make a personal solution

Create a professional team of project management

Ordering steel material and start mold processing

Weekly schedule for mold processing

Mold Trial and make samples production

Samples checking and make mold modification

Finish final version samples and mold shipment

If you need any kinds of clean room injection molding, please contact us, as a professional injection molding factory, Packson Mold is willing to offer you high quality products.

在线联系供应商

Other supplier products

| Overmolding Injection Molding | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability Overmolding... | |

| Explore Packson's Injection Molding Services | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more than 20 years exp... | |

| Prototype Injection Mould | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CNC machining, micro-injection molding, and prototyp... | |

| Silicone Rubber Mold | Silicone rubber is a kind of elastic material, which is widely used in industry and family. It has become an important part of our life. Meanwhile,... | |

| Custom Metal Machining Parts | Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more. Our t... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |