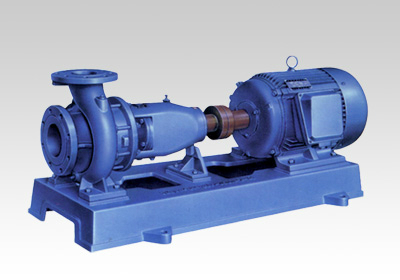

Desulfurization Pump

Product name:Desulfurization Pump

Model:Flue Gas Desulphurization Pump

Application:FGD pumps are sailed Pump Company in LC-T series slurry pump, the successful design manufactured on the basis of experience, in view of industrial flue gas

Product overview

Flue gas desulfurization pump Overview:

FGD pumps are sailed Pump Company in LC-T series slurry pump, the successful design manufactured on the basis of experience, in view of industrial flue gas desulfurization pump characteristics, absorb with similar products within and outside the advanced technology, well-developed The new generation of series desulfurization pumps. Dedicated to the absorption tower circulating pump PH: 2.5 to 13 chlorine ion concentration: ≤60000ppm weight concentration: ≤60% Medium temperature: ≤100 ℃.

Absorber circulation pump is large FGD key equipment, means there is high demand for its reliability and service life. FGD means more than half of the power consumed for driving the absorber circulation pump. Therefore, the circulating pump should have a high efficiency. Hydraulic design of the pump design and selection of materials flow components directly related to the efficiency of the pump operation, reliability and service life.

We developed the absorber circulation pump, pump, pump cover over-current parts are made of 2605N material, impeller, wear plate is used Cr30A material.

Hydraulic design of the pump, drawing the French company J · S phase flow pump design and manufacturing technology, and the use of modern CAD, CFD technical correction.

Second, the flue gas desulfurization pumps structural features:

(1) The pump is single-stage single-suction centrifugal pumps, which form in practice has proved to be particularly suitable for FGD absorber circulation pumping device abrasive, corrosive slurry.

(2) The impeller, wear plate without using mouth ring seal in the form, set the port ring will be slurry rapid wear, leading to the rapid decline in the efficiency of the pump.

(3) having an axial adjustment structure, the impeller can be easily adjusted to maintain an axial gap between the impeller and the wear plate and the front cover, so as to maintain the high efficiency of the pump. It is always easiest to maintain and the most effective and efficient way to pump operation.

(4) is arranged in the form of pump is "pull" structure. This allows the pump impeller during disassembly, mechanical seals and shaft assembly without removing the inlet and outlet pipes.

(5) bearing with thin oil lubrication. Bearing mounted on a rubber ring secondary seal removable bearing box, to prevent dirt and water from entering.

(6) The shaft is a large diameter, short axis head can reduce shaft deflection at work, thus extending seal life.

Third, the flue gas desulfurization pump design advantages:

Overview: back pull-out design of the entire rotor assembly can be pulled from the motor, easy to maintain, the pump can remain in the pipeline, without removing the motor.

1. Front pull-out design wear plates, impellers, mechanical seal can be disassembled inlet end

2. bearing bracket can be adjusted to improve the wear resistance

3. The bearing lubrication oil immersion

4. Pump: pump pressure and wear of sufficient size, materials used 2605N, weldable, volute tongue wear some special treatment, tangential flow channel outlet, the body set foot supporting way.

5. Wear plates: the part is mounted between the pump and imported materials Cr30A, this material has excellent resistance to abrasion and erosion resistance, overall performance, thereby extending the life of the pump and impeller.

6. Impeller: material Cr30A, not welded, taking into account the long run is more economical, since the bearing holder can be adjusted when the situation abrasive wheel, the wheel can be re-processed and prolong life. Front blade structure prevents large particles rushed impeller and wear plate gap, the leading blade and wear plate gap, reducing the media (in impeller and wear plate) flow rate, reducing wear, special blades wear process design, back blade design, reduced axial force, but also to block large particles, high pressure bearing design (simulation without axial force hydraulic model back under the blade), the

7. impeller vent design, can be discharged within the gaseous medium, to prevent dry running mechanical seals.

8. After the pump cover: materials used 2605N, weldable, wear usually occurs in the back of the blade area, the pump head is mounted on the bearing bracket, release stress and allow greater wear and prolong the service life of the pump cover bolts fixed bearing frame for easy disassembly without the card and damage to the pump when dismantling the mechanical seal.

9. A bearing body: the bearing body consists of two parts, the carrier and the bearing housing, the bearing housing and the adjusting screw can be adjusted by means of bolts, move horizontally within the carriage. This has the advantage: in the bearing housing to move the carriage (reprocessing size according impeller), but the inner and outer bearing ring without relative displacement, since no relative displacement, seals fully functional. When removing the lower part of the reservation on the base for easy removal, position accuracy, the installation will not occur mutual jamming of parts.

10. Mechanical seal: The mechanical seal is designed to Single seal cartridge structure, easy disassembly. Wash design there are two options: one, loaded wash water pipe fixed wash water; of the two, without a fixed wash water line, segmental wash. In the mechanical seal the work area, if the medium containing gas, mechanical seals would run dry, so the impeller is designed with vents, you can avoid large, dirty particle contact mechanical seal. Easy emptying drainage pump seal cavity volume, full lubrication, cooling sufficiently.

slurry pump China/factory/supplier/manufacturer/exporter, gravel pump China/factory/supplier/manufacturer/exporter,mud pump China/factory/supplier/manufacturer/exporter, desulfurization pump China/factory/supplier/manufacturer/exporter,swage pump China/factory/supplier/manufacturer/exporter, sage pump China/factory/supplier/manufacturer/exporter,centrifugal pump China/factory/supplier/manufacturer/exporter,industry pump China/factory/supplier/manufacturer/exporter

Shi jia zhuang Bojin pump co.,ltd

Contact: Johnny

Address: No.266 Tianshan Street Shijiazhuang,Hebei Province,China

Tel:

Mobile:

Website:

E-mail:

Postal Code: 050035

在线联系供应商

Other supplier products

| ZHJ Type Mechanical Seal | Product name:ZHJ Type Mechanical Seal Model:ZHJ Type Single-end Mechanical Seal Application:ZHJ Type Single-end Mechanical Seal M Slurry Pump Ch... | |

| LG Vertical Multistage Pump | Product name:LG Vertical Multistage Pump Model:LG Vertical Multistage Pump Application:LG-type multi-stage high-rise buildings to pump Product Ov... | |

| SP Slurry Pump | Product name:SP Slurry Pump Model:SP Slurry Pump Application:The pump is a vertical centrifugal slurry, under immersion fluid, suitable for conve... | |

| IS Centrifugal Pump | Product name:IS Centrifugal Pump Model:IS Centrifugal Pump Application:IS clean water pump for industrial and urban water supply, drainage, can a... | |

| GC Centrifugal Pump | Product name:GC Centrifugal Pump Model:GC Centrifugal Pump Application:GC type pump is horizontal, single suction multistage centrifugal pumps P... |

Same products

| ZGD螺杆式家用增压泵 | 卖方: 才福泵业有限公司 | ZGD螺杆式家用增压泵是一款功能多样、性能可靠的解决方案,专为提升家庭用水压力而设计。该泵采用精密工艺和优质材料制造,运行流畅稳定,可确保满足各种家庭用水需求,提供持续稳定的水流。 | |

| V(WQ) One-Way Submersible Sewage Pump | 卖方: Taizhou Yuansheng Aquacul Ture Machinery Co., Ltd. | TheV(WQ) One-Way Submersible Sewage Pumpis designed for wastewater and sewage transfer in residen... | |

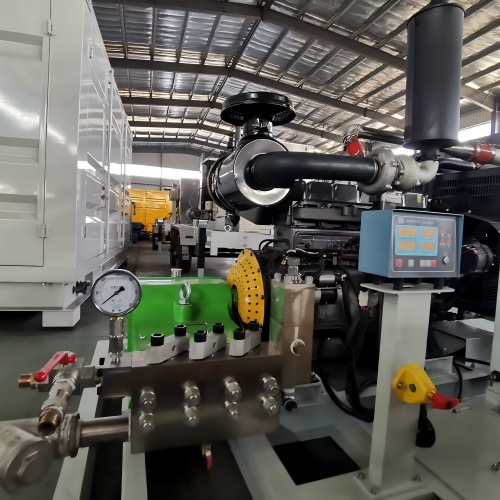

| Multi Purpose High Pressure Pump for Water Jet Cleaning | 卖方: Tianjin Harvest High Pressure Pump Co., Ltd | 3D2F-S pump is our company's latest patented product with a maximum working pressure of 150... | |

| Water Injection Pump for Tertiary Oil Recovery Applications | 卖方: Tianjin Harvest High Pressure Pump Co., Ltd | This pump is suitable for pipeline cleaning ,workpipe cleaning,sand cleaning,rust removal,l... | |

| Secondary Recovery High flow Pump | 卖方: Tianjin Harvest High Pressure Pump Co., Ltd | 3D2C-S series high pressure plunger pump is an improved product of 3D2A-S series high press... |